Updated: November 11, 2014 (Originally published November 13, 2013)

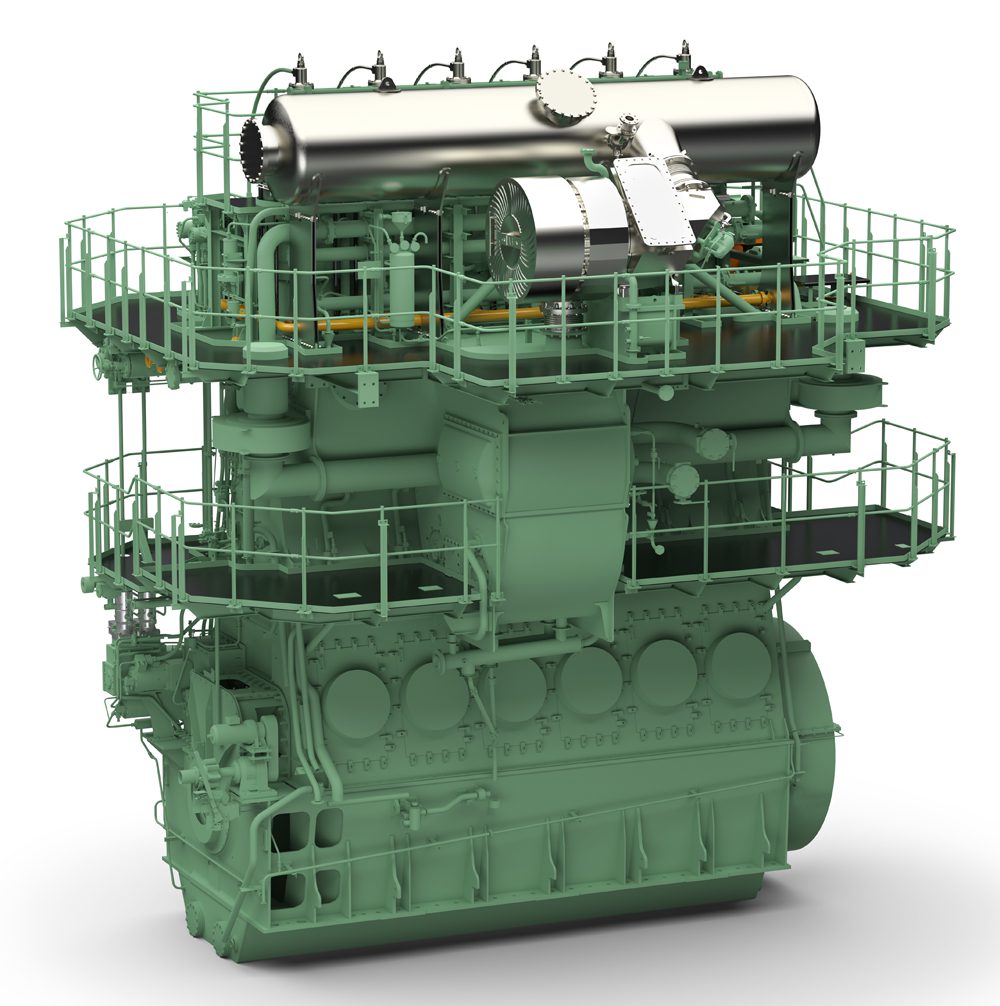

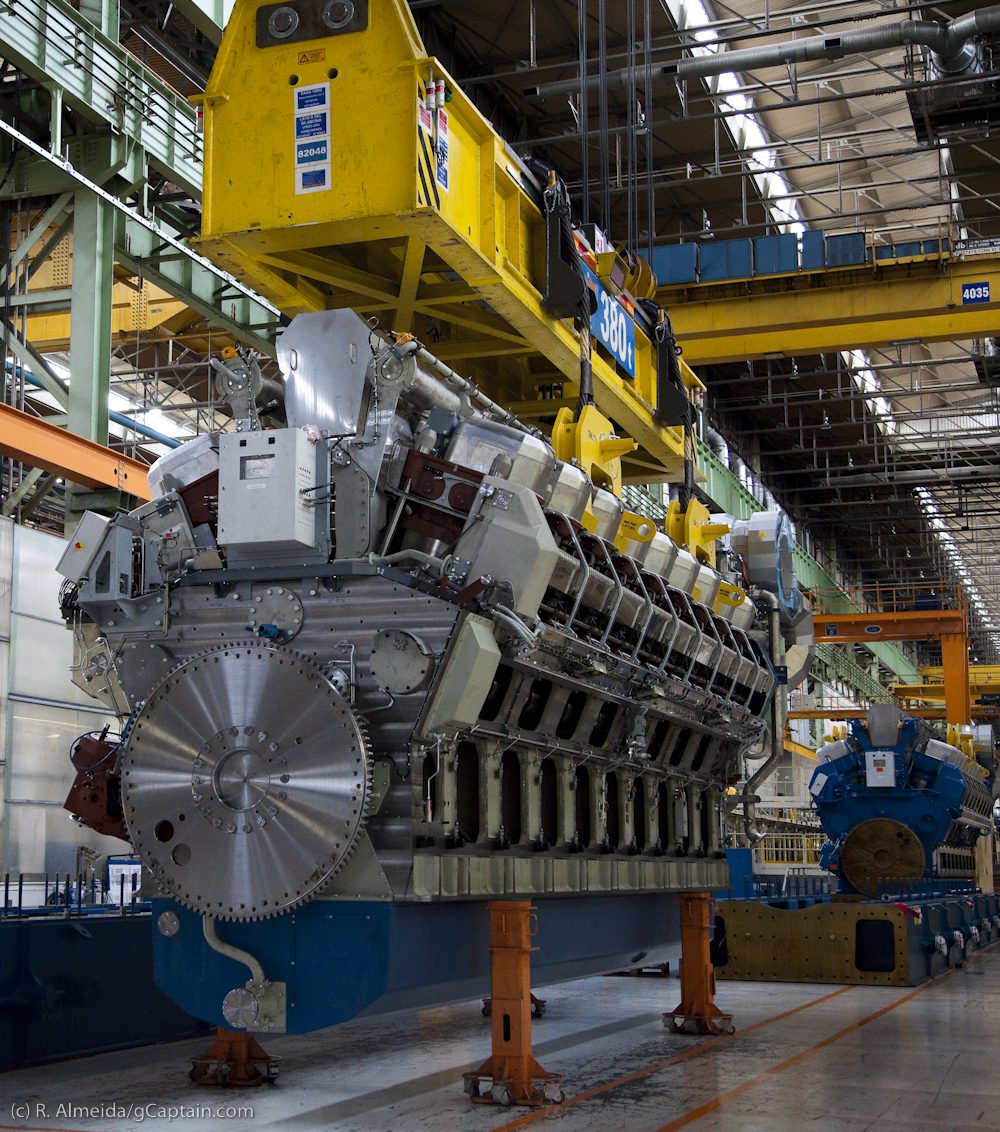

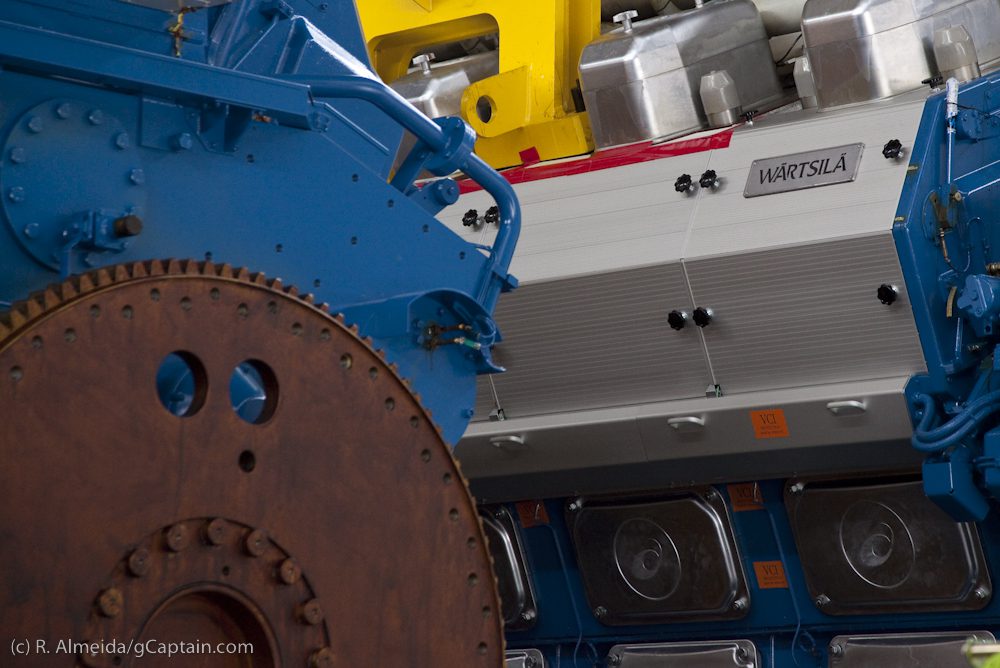

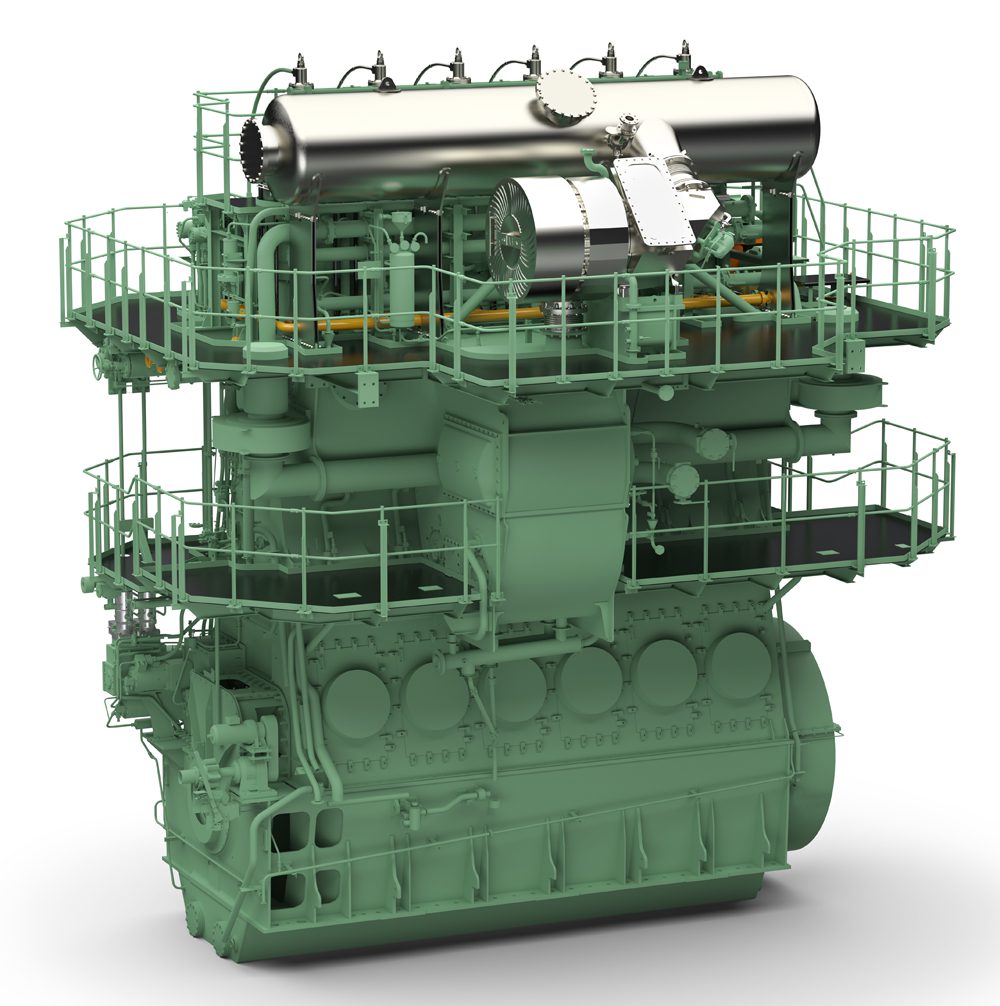

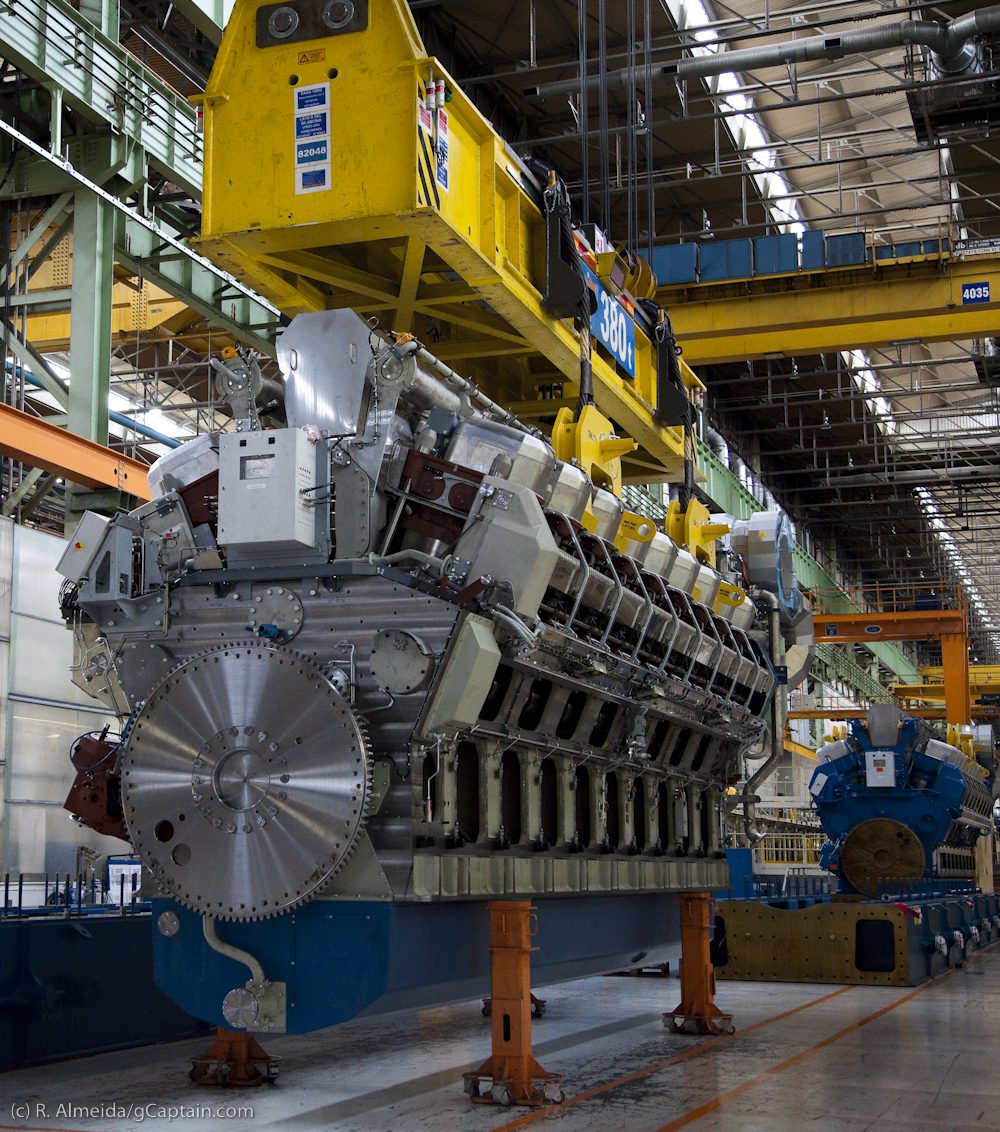

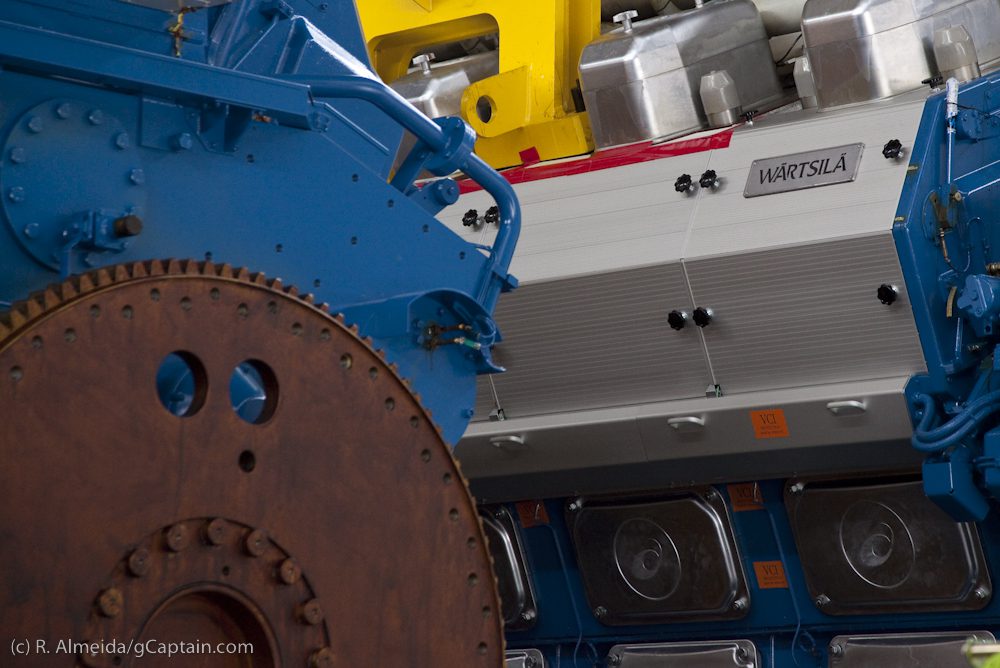

At a press event in Trieste, Italy this week, Finnish marine engine manufacturer Wärtsilä pulled the curtain to reveal the RT-flex 50DF, the world’s first 2-stroke, low-pressure, dual fuel engine. By all accounts this is a very unique engine, one that Wärtsilä emphatically declares will be a game-changer for the shipping business.

Although Wärtsilä is not the first engine manufacturer to introduce a 2-stroke dual fuel engine, the technology inside the engine enables it to operate seamlessly with two different fuels while far surpassing IMO Tier III emissions regulations without the use of emissions after treatment systems.

No other 2-stroke engine in the world can achieve this.

The key to such low emissions is the engine’s low pressure fuel system. Instead of pumping gas at 300 bar into the engine near Top Dead Center (TDC), gas is ported into the engine mid stroke at less than 10 bar which allows the gas to mix thoroughly into the cylinder and subsequently burn more evenly. This pre-mixed lean burn combustion process results almost zero NOx emissions. In addition, because this is a low pressure system, high pressure compression systems are not required.

Wärtsilä noted in their presentation that the flame created in a high pressure gas engine burns in a far different manner resulting in the creation of NOx at levels well outside the limits required by IMO Tier III .

In the RT-flex 50DF, the ignition process is started via the combustion of a 1% portion of diesel in a pre-chamber. When in gas-mode, this portion of diesel is the primary contributor of NOx emissions.

When speaking about gas-powered engines, the emission of unburned fuel into the atmosphere is always an important factor as natural gas has upwards of 25 times the potency as a greenhouse gas as compared to CO2. Wärtsilä’s Vice President of 2-Stroke Ship Power, Dr. Martin Wernli notes that “methane slip” inherent in the RT-flex 50DF engine is less than what is found in the equivalent 4-stroke engine and still results in 25 percent less equivalent CO2 emissions.

Because this engine burns diesel fuel, a relatively expensive fuel, and natural gas, a fuel that is priced quite variably depending on the geographic region, the target market for this engine would appear to be companies that operate on long-term charters between ports that are currently expanding their LNG bunkering capabilities. Wärtsilä’s Director of 2-Stroke Engine Sales, Rolf Stiefel, notes that most of the big European ports, as well as Fujairah, Busan, Incheon, Singapore, and Buenos Aires have definitive plans to expand their LNG bunkering facilities while dozens more around the world are currently in the planning stage.

Stiefel notes that an announcement may occur in the very near future regarding the first order for such an engine. First engine delivery is planned for Q3 2014.

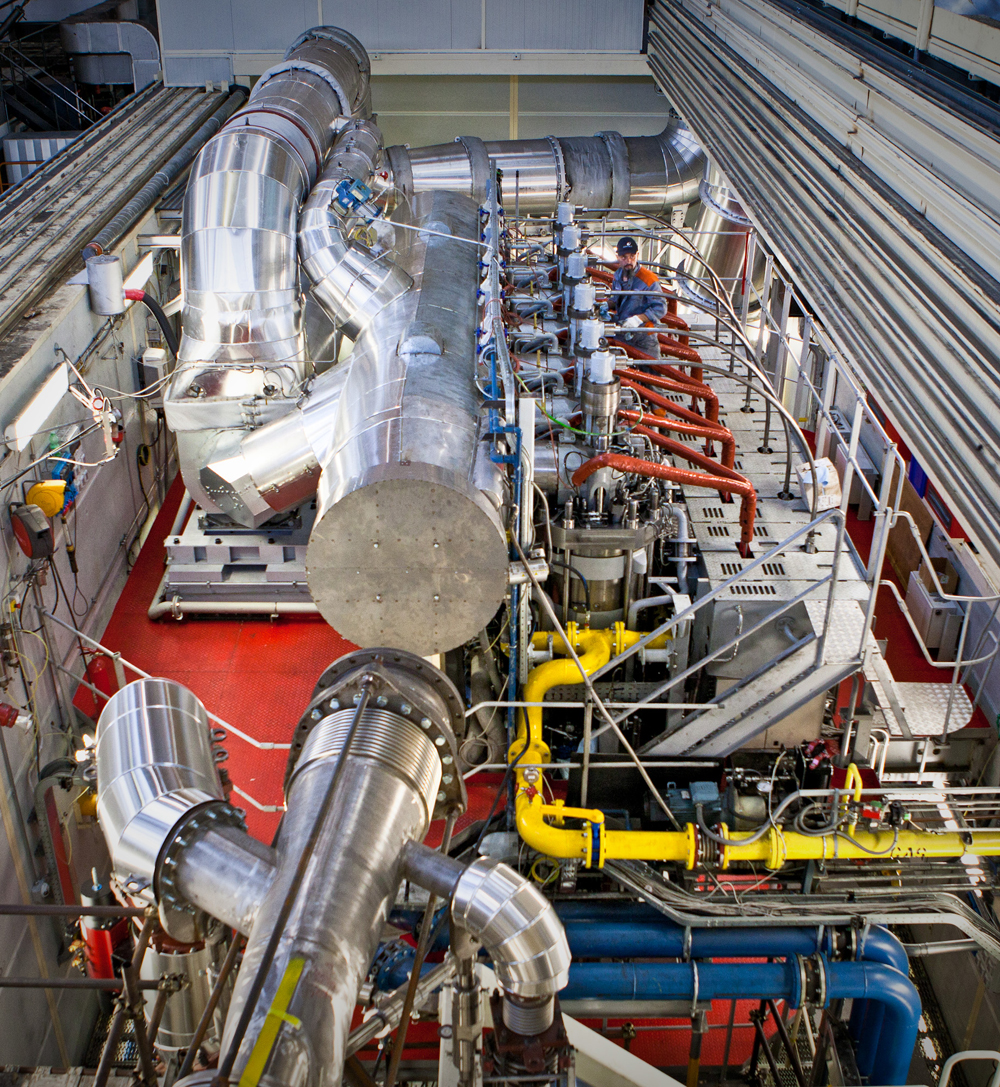

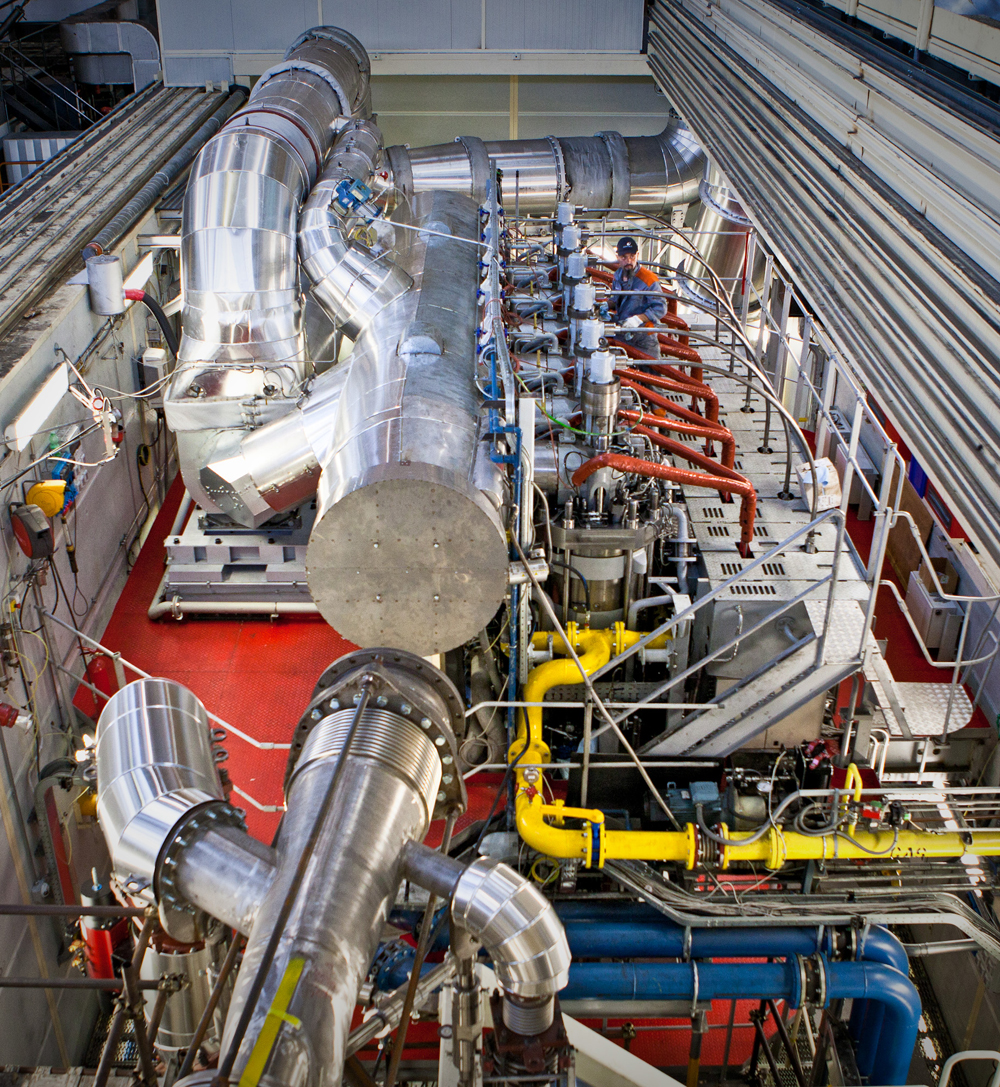

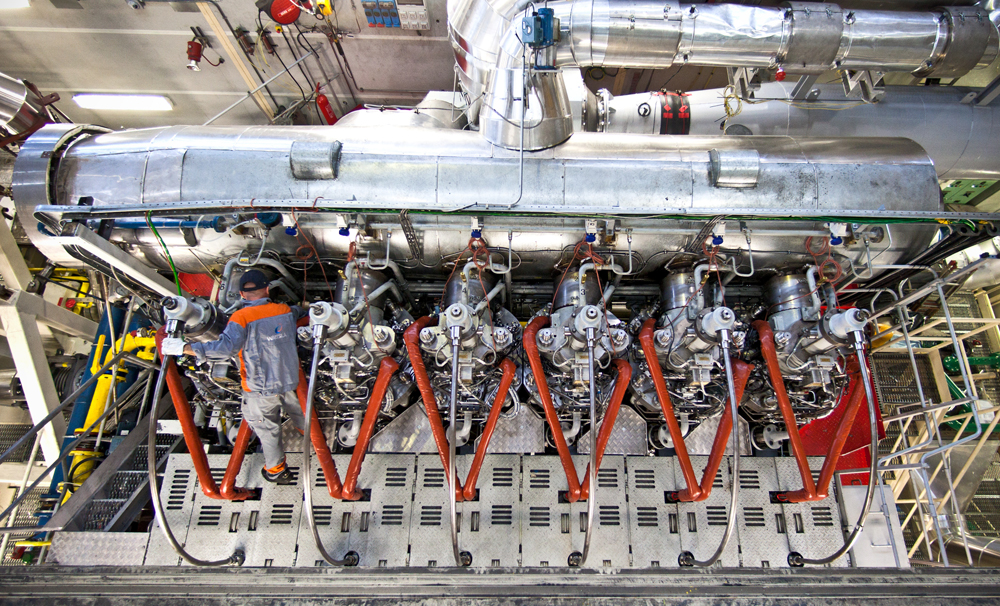

Besides unveiling their skunkworks dual fuel operations, Wärtsilä showed us around their European manufacturing headquarters, a facility they claim is the largest engine manufacturing facility in Europe which produces about 200 engines per year.

The following images may not be copied or reproduced in any way without written permission from gCaptain and Wärtsilä.

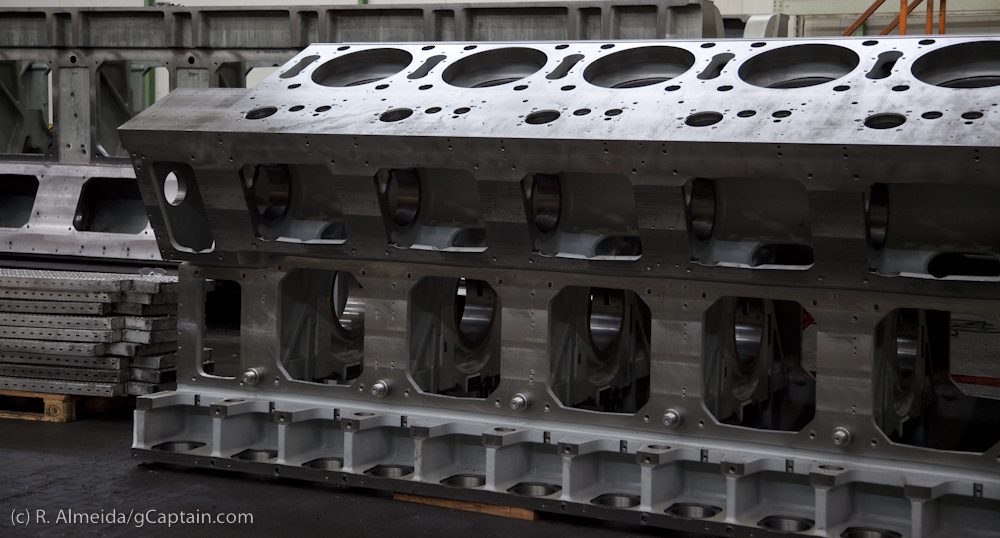

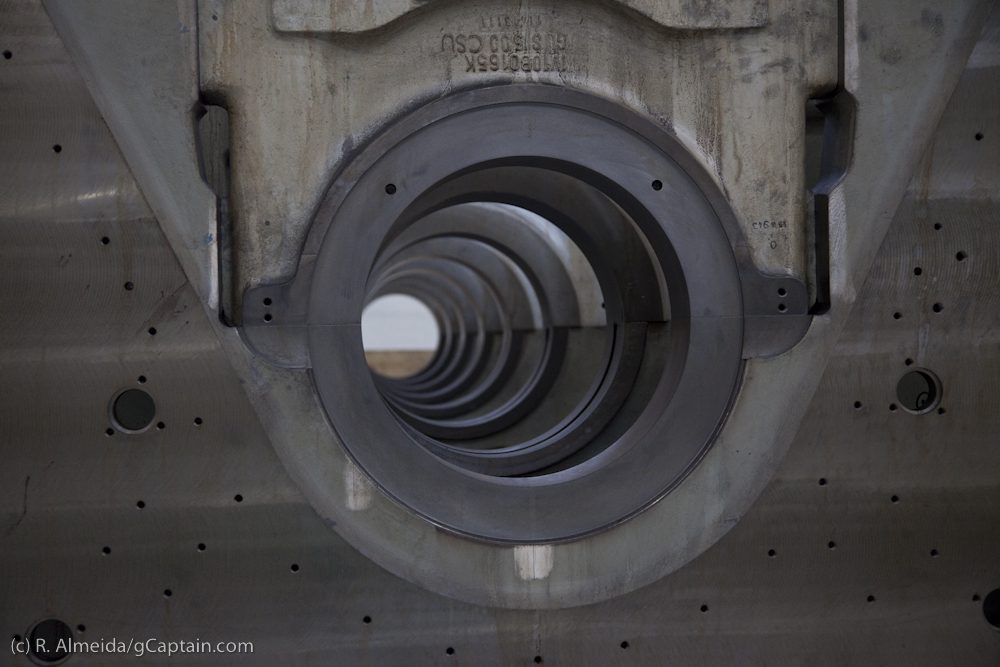

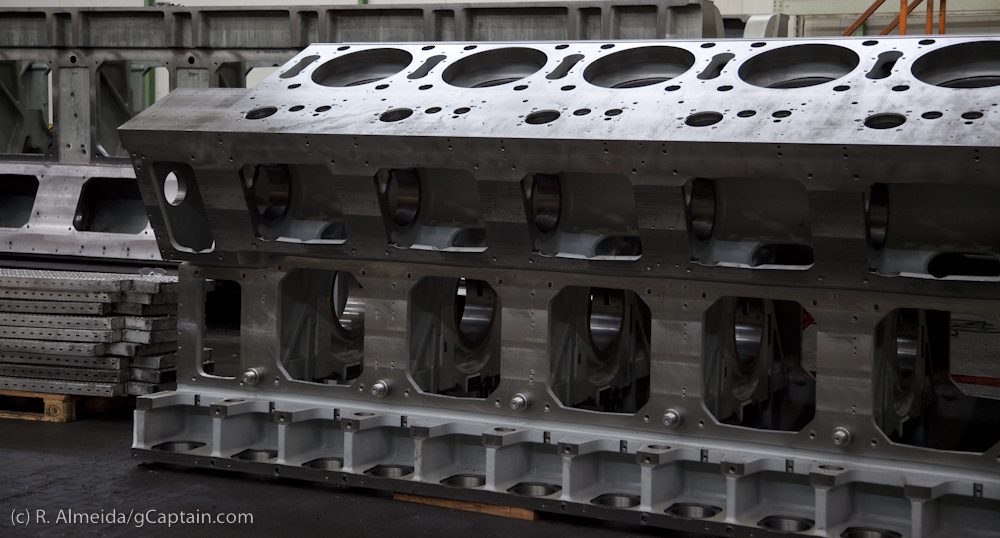

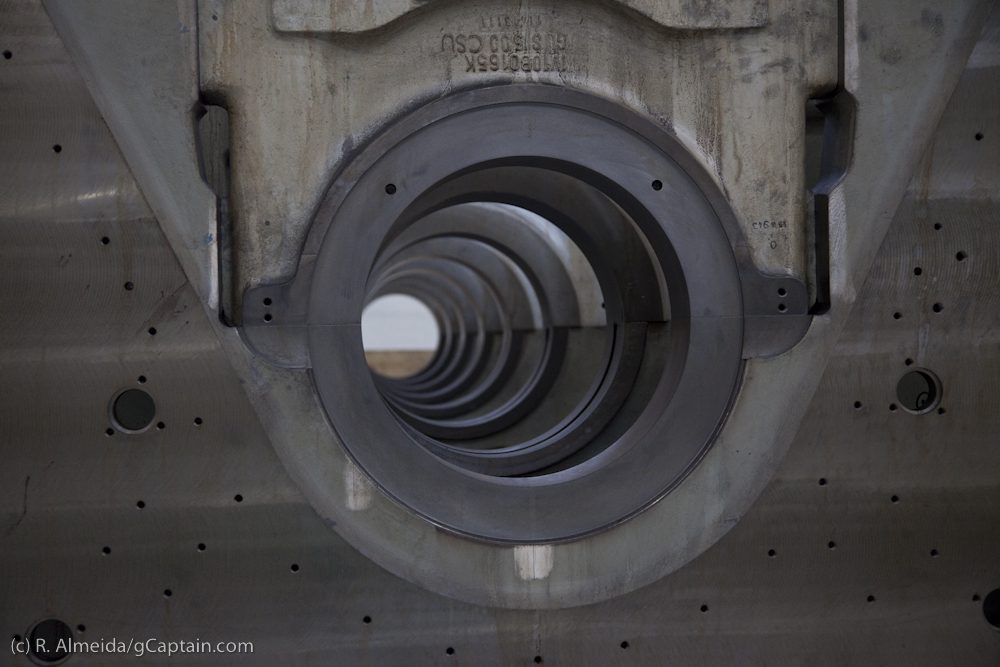

Once the casted blocks arrive, they are run through giant, and very expensive, CNC milling machines to get the steel blocks to the micro-level tolerances needed.

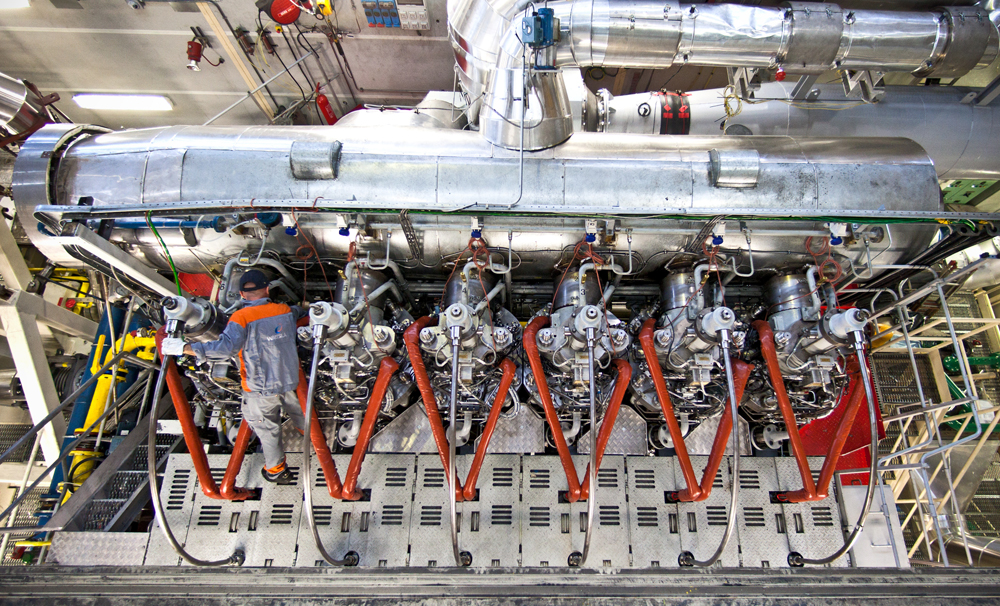

After milling, mechanics begin the work of preparing all the surfaces and hundreds of bits and pieces that will soon be meticulously put into place.

Wärtsilä’s Director of Manufacturing Development, Paolo Pierdomenico notes that considering the engine blocks of a particular power range are a standard size, the liners pictured below can be changed out in order to upgrade an engine from conventional fuel to dual fuel. That is, going from a 46cm conventional engine to a 50cm dual fuel is a matter of a liner changeout, plus a few other relatively simple modifications.

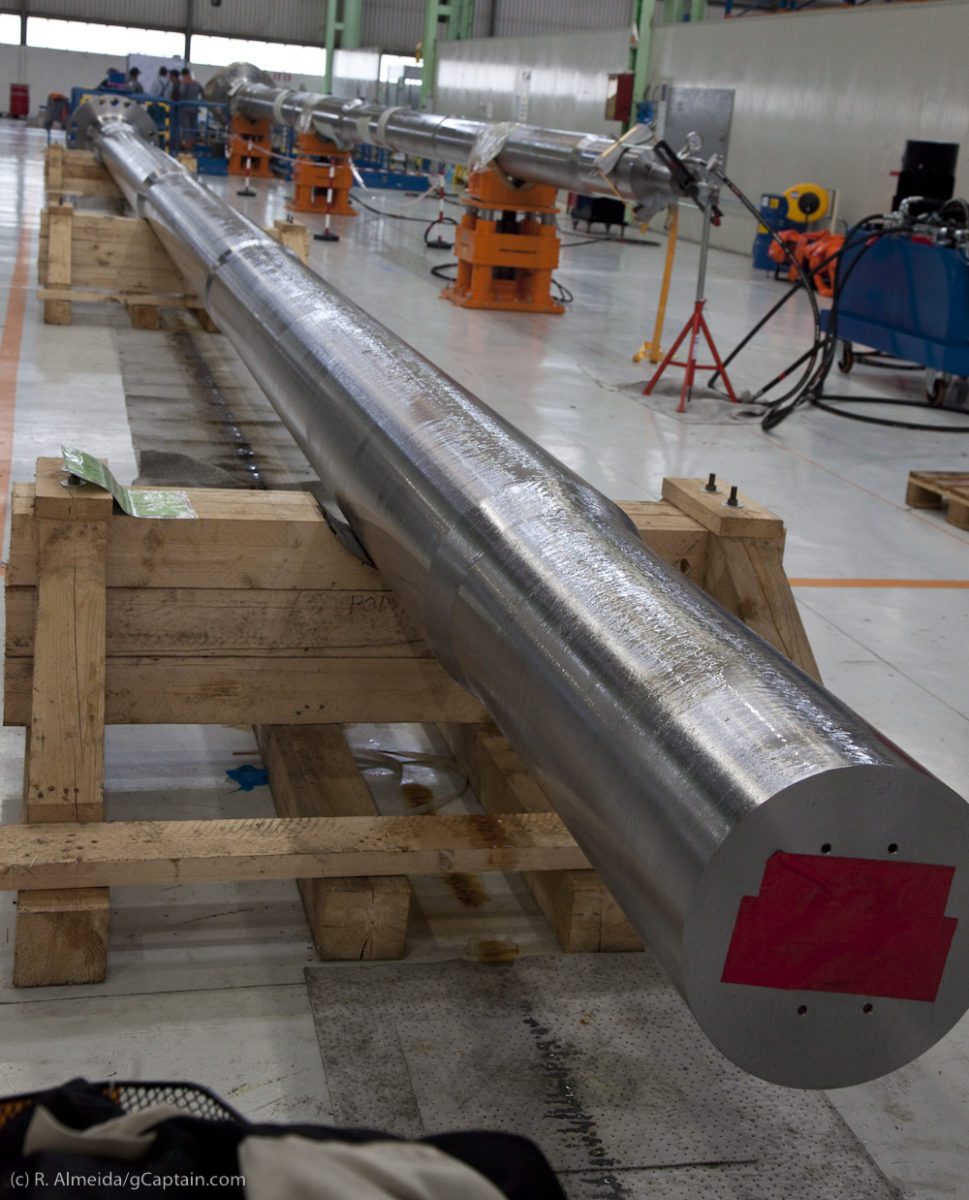

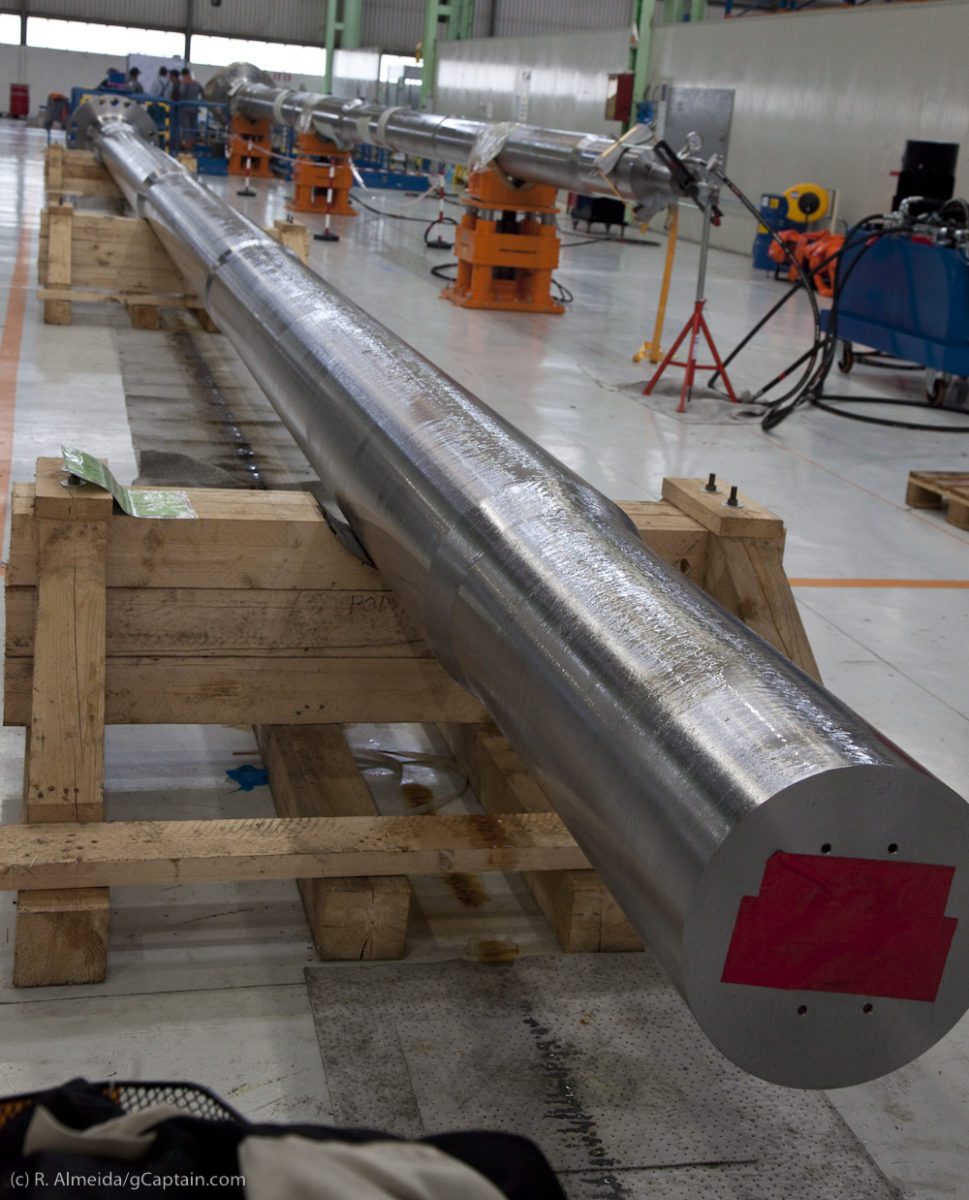

Besides building engines at their Trieste facility, Wärtsilä is also busy putting together propulsion systems such as the controllable pitch propeller shaft pictured below.

Editorial Standards · Corrections · About gCaptain

Join The Club

Join The Club