Second Gaza Relief Aid Ship Leaves Port

By Yiannis Kourtoglou (Reuters) – Ships carrying 332 tons of food for Gaza left Cyprus’s Larnaca port on Saturday in a convoy which will reach the besieged enclave early next week, authorities said. It...

Wärtsilä put together a presentation recently that evaluated a number of new technologies and design concepts aimed at cutting operating costs, while at the same time reducing ship emissions.

Combining these areas and treating them together as an integrated solution can result in truly efficient ship operations.

The following are design concepts and their associated contribution to a more efficient ship design.

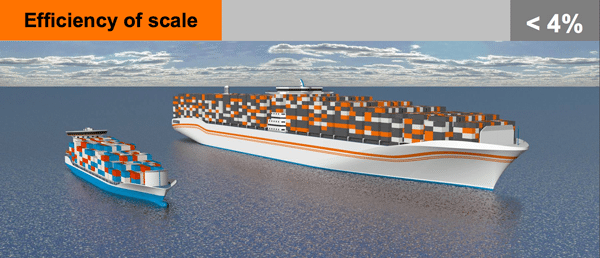

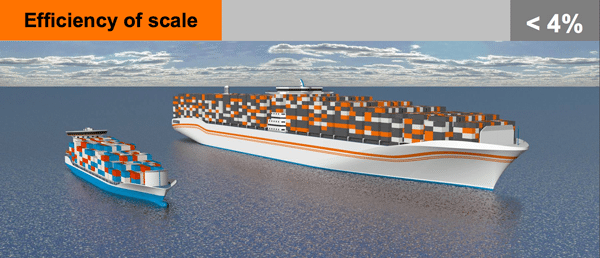

A larger ship will in most cases offer greater transport efficiency due to efficiency of scale. A larger ship can transport more cargo at the same speed with less power per cargo unit. Limitations may be met in port handling.

Regression analysis of recently built ships show that a 10% larger ship will give about 4-5% higher transport efficiency.

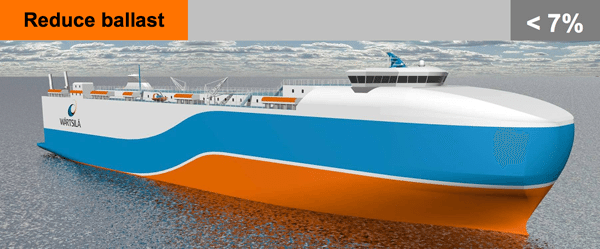

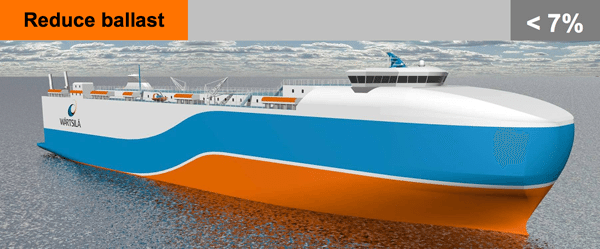

Minimising the use of ballast (and other unnecessary weight) results in lighter displacement and thus lower resistance. The resistance is more or less directly proportional to the displacement of the vessel. However there must be enough ballast to immerse the propeller in the water, and provide sufficient stability (safety) and acceptable sea keeping behaviour (slamming).

Removing 3000 tons of permanent ballast from a PCTC and increasing the beam by 0.25 metres to achieve the same stability will reduce the propulsion power demand by 8.5%.

The use of lightweight structures can reduce the ship weight. In structures that do not contribute to ship global strength, the use of aluminium or some other lightweight material may be an attractive solution.

The weight of the steel structure can also be reduced. In a conventional ship, the steel weight can be lowered by 5-20%, depending on the amount of high tensile steel already in use.

A 20% reduction in steel weight will give a reduction of ~9% in propulsion power requirements. However, a 5% saving is more realistic, since high tensile steel has already been used to some extent in many cases.

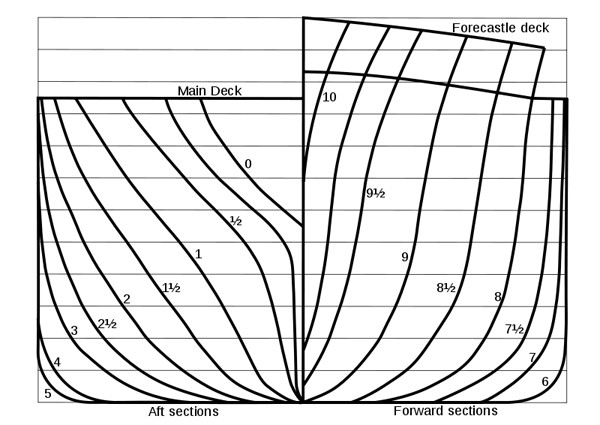

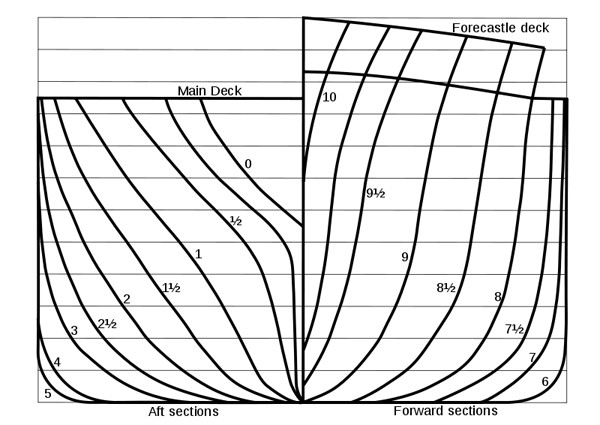

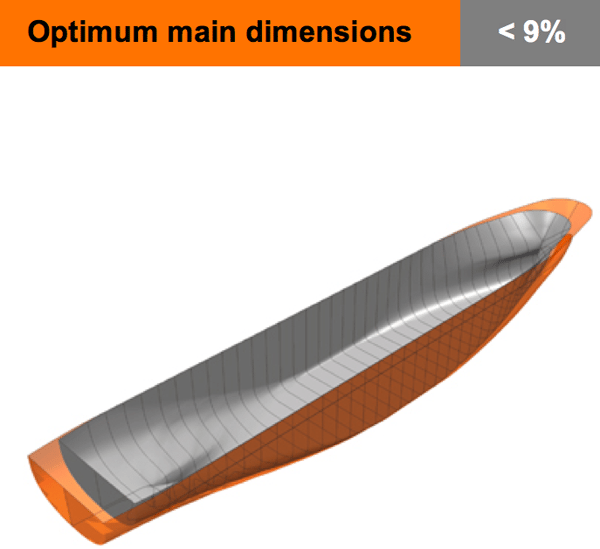

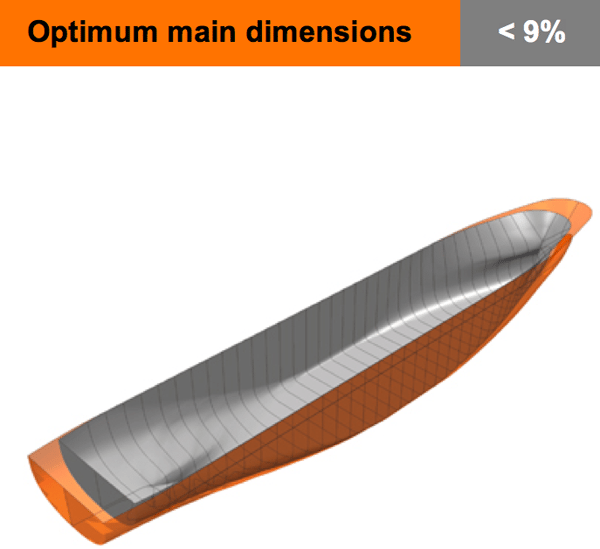

Finding the optimum length and hull fullness ratio (Cb) has a big impact on ship resistance.

A high L/B ratio means that the ship will have smooth lines and low wave making resistance. On the other hand, increasing the length means a larger wetted surface area, which can have a negative effect on total resistance.

A too high block coefficient (Cb) makes the hull lines too blunt and leads to increased resistance.

Adding 10-15% extra length to a typical product tanker can reduce the power demand by more than 10%.

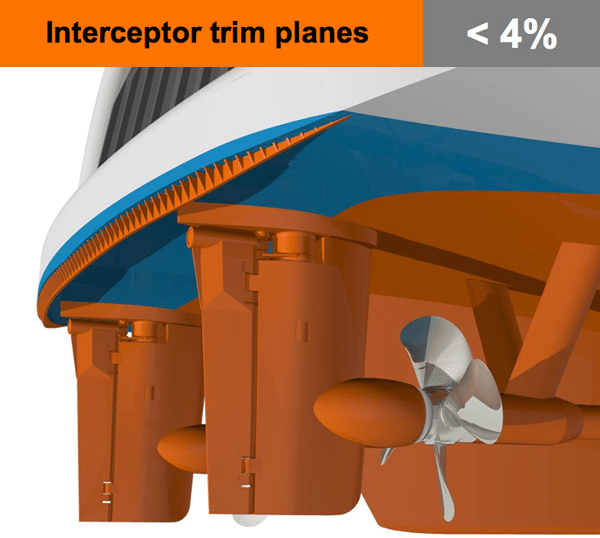

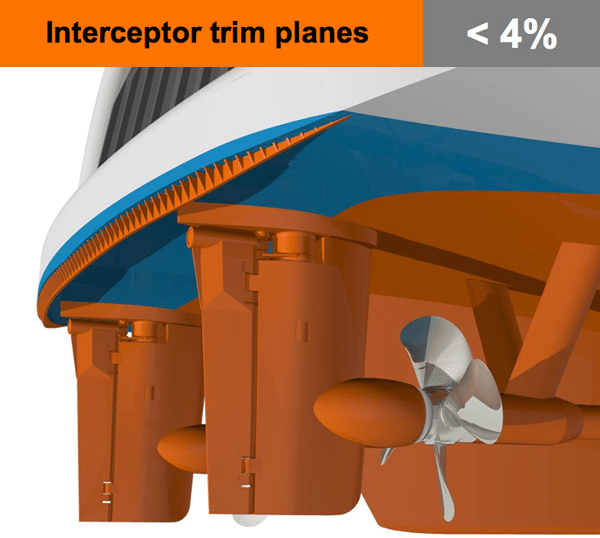

The Interceptor is a metal plate that is fitted vertically to the transom of a ship, covering most of the breadth of the transom. This plate bends the flow over the aft-body of the ship downwards, creating a similar lift effect as a conventional trim wedge due to the high pressure area behind the propellers. The interceptor has proved to be more effective than a conventional trim wedge in some cases, but so far it has been used only in cruise vessels and RoRos. An interceptor is cheaper to retrofit than a trim wedge.

1-5% lower propulsion power demand. Corresponding improvement of up to 4% in total energy demand for a typical ferry.

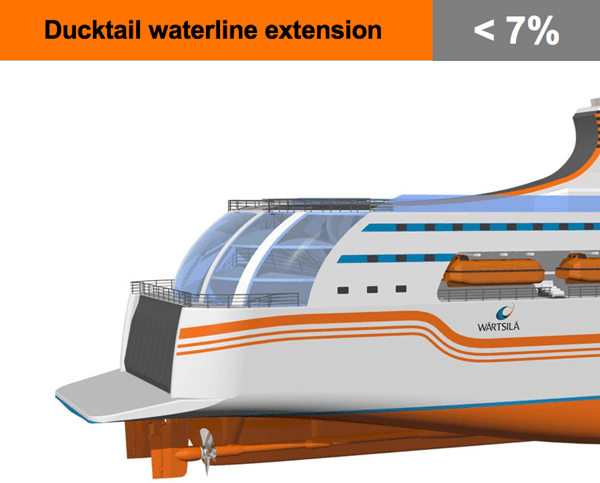

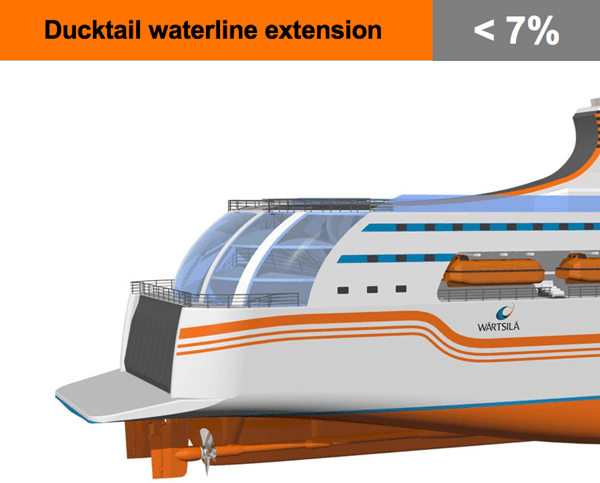

A ducktail is basically a lengthening of the aft ship. It is usually 3-6 meter long. The basic idea is to lengthen the effective waterline and make the wetted transom smaller. This has a positive effect on the resistance of the ship. In some cases the best results are achieved when a ducktail is used together with an interceptor.

4-10% lower propulsion power demand. Corresponding improvement of 3-7% in total energy consumption for a typical ferry.

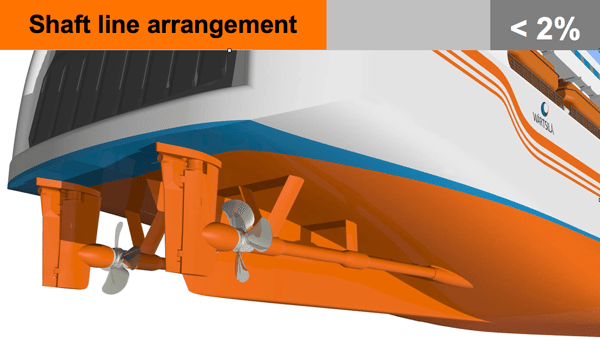

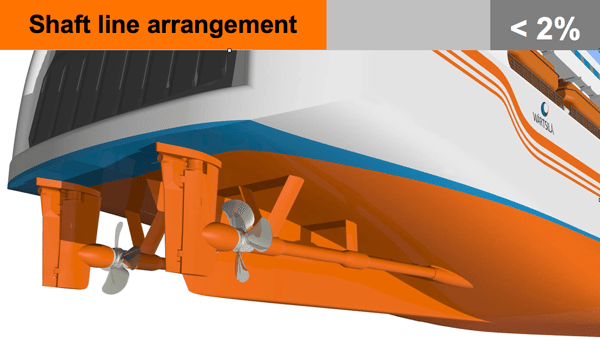

The shaft lines should be streamlined. Brackets should have a streamlined shape. Otherwise this increases the resistance and disturbs the flow to the propeller.

Up to 3% difference in power demand between poor and good design. A corresponding improvement of up to 2% in total energy consumption for a typical ferry.

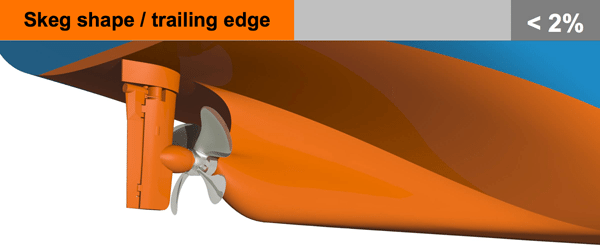

The skeg should be designed so that it directs the flow evenly to the propeller disk. At lower speeds it is usually beneficial to have more volume on the lower part of the skeg and as little as possible above the propeller shaftline. At the aft end of the skeg the flow should be attached to the skeg, but with as low flow speeds as possible.

1.5%-2% lower propulsion power demand with good design. A corresponding improvement of up to 2% in total energy consumption for a container vessel.

The water flow disturbance from openings to bow thruster tunnels and sea chests can be high. It is therefore beneficial to install a scallop behind each opening. Alternatively a grid that is perpendicular to the local flow direction can be installed. The location of the opening is also important.

Designing all openings properly and locating them correctly can give up to 5% lower power demand than with poor designs. For a container vessel, the corresponding improvement in total energy consumption is almost 5%.

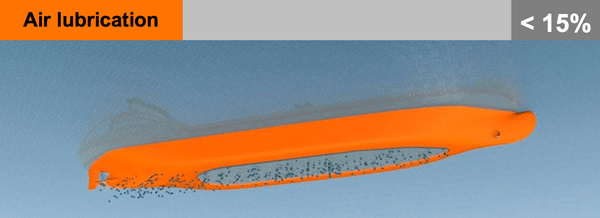

Compressed air is pumped into a recess in the bottom of the ship’s hull. The air builds up a carpet that reduces the frictional resistance between the water and the hull surface. This reduces the propulsion power demand. The challenge is to ensure that the air stays below the hull and does not escape. Some pumping power is needed.

Saving in fuel consumption:

Part 2 of this series focuses on ship propulsion technology.

Join the gCaptain Club for curated content, insider opinions, and vibrant community discussions.

Join the 105,417 members that receive our newsletter.

Have a news tip? Let us know.

Access exclusive insights, engage in vibrant discussions, and gain perspectives from our CEO.

Sign Up

Maritime and offshore news trusted by our 105,417 members delivered daily straight to your inbox.

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up