This milestone reflects Bardex’s commitment to precision, reliability, and on-time project delivery.

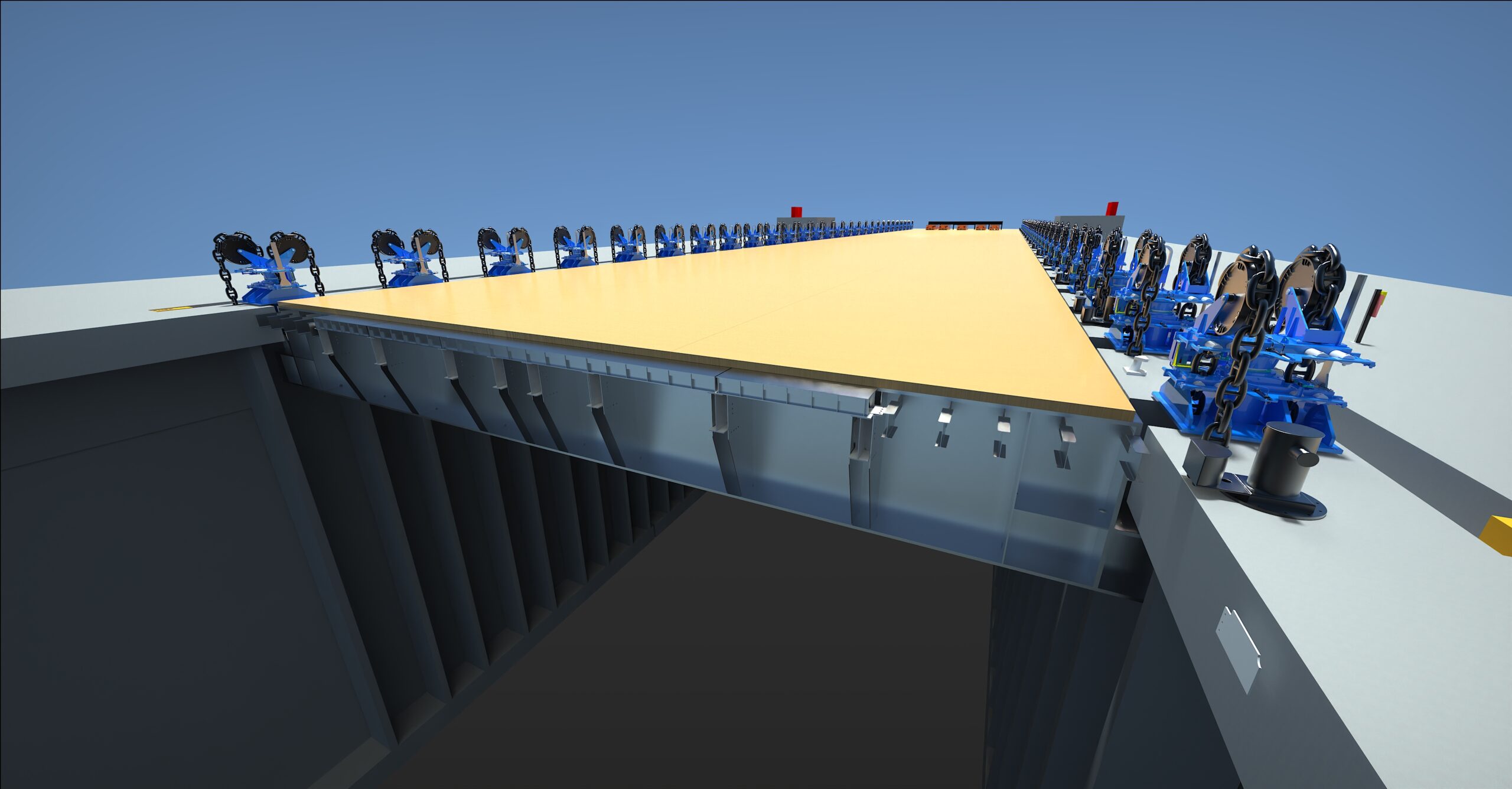

Bardex, in partnership with Irving Shipbuilding, Inc., today announced that production has commenced on the mechanical equipment for the Irving OmniLift Shiplift, marking a critical milestone on the project timeline. This specialized set of equipment, designed and engineered to meet exacting standards, will play a central role in supporting Irving’s River-class destroyer shipbuilding program, a part of the National Shipbuilding Strategy and the most complex Canadian shipbuilding program since World War II.

The move into production reflects Bardex’s ongoing commitment to precision, reliability, and on-time project delivery. Every stage of the build is being carefully managed to ensure the highest quality standards are met, demonstrating the company’s expertise in delivering complex, high-value engineering solutions.

“Advancing into production is a proud milestone that underscores our ability to transform complex designs into reliable, precision-engineered equipment,” said Sarah Finn, Senior Project Manager. “It reflects the strength of our team and partners, whose focus and collaboration ensure we remain on track to deliver successfully on a program of this scale.”

About Irving Shipbuilding, Inc.: Irving Shipbuilding is Canada’s National Shipbuilder, selected in 2011 to build the new fleet of combat vessels for the Royal Canadian Navy (RCN). To date, six Arctic and Offshore Patrol Ships (AOPS) have been delivered to the RCN and a further two are under construction for the Canadian Coast Guard. Construction of the larger River-class destroyer Fleet began in April 2025. The team of 2,400 shipbuilders is proudly based in Halifax, NS, and includes the largest team of apprentices in Atlantic Canada. shipsforcanada.ca

About Bardex Corporation: Bardex provides novel engineering insights and designs, prototypes, and manufactures proprietary equipment to solve the marine industry’s heaviest challenges. For over 60 years – and 300+ projects for shipyards, ports, and the offshore energy industries – the Bardex mindset has always been to be a trusted, collaborative partner whose first step in any project is to understand exactly what the client needs to accomplish. That approach has produced more than 20 patents, many repeat clients, and countless innovations that make the seemingly impossible possible, while improving safety, efficiency, and our clients’ profitability for a diverse range of applications. Bardex manufacturing facilities are ISO 9001, ISO 14001, and ISO 45001 certified. To learn more, visit https://www.bardex.com, and follow them on LinkedIn to stay in touch.

Join The Club

Join The Club