Houthi Video Shows Sinking of M/V Magic Seas in Red Sea

Yemen’s Houthi militants have released propaganda footage appearing to show the Greek bulk carrier M/V Magic Seas sinking in the Red Sea following their attack on July 6. The vessel...

Incidents always have a human factor. Fathers are lost at sea leaving friends, family, wives and sometimes young children behind. Media reports and incident investigations or official reports may highlight the financial loss or the operational downtime but it takes an exceptionally sad case to shine light on the human factor, the loss of loved ones. The loss of the Bourbon Dolphin is such a case.

Back in October Maritime Accident Casebook told us:

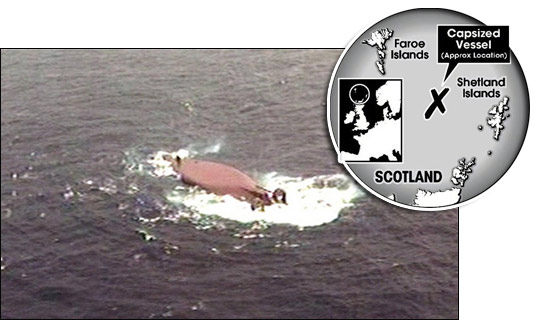

Six months after her capsize near the Chevron drilling rig, Transocean Rather, 85 miles west of the Shetlands on April 12 this year, a preliminary report on the AHTS Bourbon Dolphin incident and the loss of eight lives, including a 14 year old schoolboy has been released. It may raise more questions than it answers and those may have to wait until the official Norwegian report is issued next year.

Of those on the bridge when she capsized, only the second mate, Geir Syversen, survived. His testimony indicates that problems began at a very early stage and emergency systems triggered just before the capsize did not work.

This week the incident report has been released and gCaptain forum member TEngineer gives us the bulletpoint details of the Bourbon Dolphin Incident Report;

Key conclusions are:

The master was given 1½ hours to familiarise himself with the crew and vessel and the ongoing operation. In its safety management system the company has a requirement that new crews shall be familiarised with (inducted into) the vessel before they can take up their duties on board. In practice the master familiarises himself by overlapping with another master who knows the vessel, before he himself is given the command.

• The Norwegian classification society Det norske Veritas (DNV) and the Norwegian Maritime Directorate were unable to detect the failures in the company’s systems though their audits.

• In specifying the vessel, the operator did not take account of the fact that the real bollard pull would be materially reduced through use of thrusters. In practice the “Bourbon Dolphin” was unsuited to dealing with the great forces to which she was exposed.

• The mooring system and the deployment method chosen were demanding to handle and vulnerable in relation to environmental forces.

• Planning of the RMP was incomplete. The procedure lacked fundamental and concrete risk assessments. Weather criteria were not defined and the forces were calculated for better weather conditions than they chose to operate in. Defined safety barriers were lacking. It was left to the discretion of the rig and the vessels whether operations should start or be suspended.

• In advance of the operation no start-up meeting with all involved parties was held. The vessels did not receive sufficient information about what could be expected of them, and the master misunderstood the vessel’s role.

• The procedure demanded the use of two vessels that had to operate at close quarters in different phases during the recovery and deployment of anchors.

• The increased risk exposure of the vessels was not reflected in the procedure. The procedure lacked provisions for alternative measures (contingency planning), for example in uncontrollable drifting from the run-out line. Nor were there guidelines for when and in what way such alternative measures should be implemented and what if any risk these would involve.

Video of the capsized vessel

Below is the initial media report and the simulation of the incident but first be sure to look at the official report, the press conference and MAC’s commentary.

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Stay informed with the latest maritime and offshore news, delivered daily straight to your inbox

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up