Major Cocaine Bust: UK Border Force Seizes Record Shipment at London Gateway

In one of the UK’s largest drug seizures of the past decade, UK Border Force officers have seized cocaine with an estimated street value of £96 million (USD 130 million)...

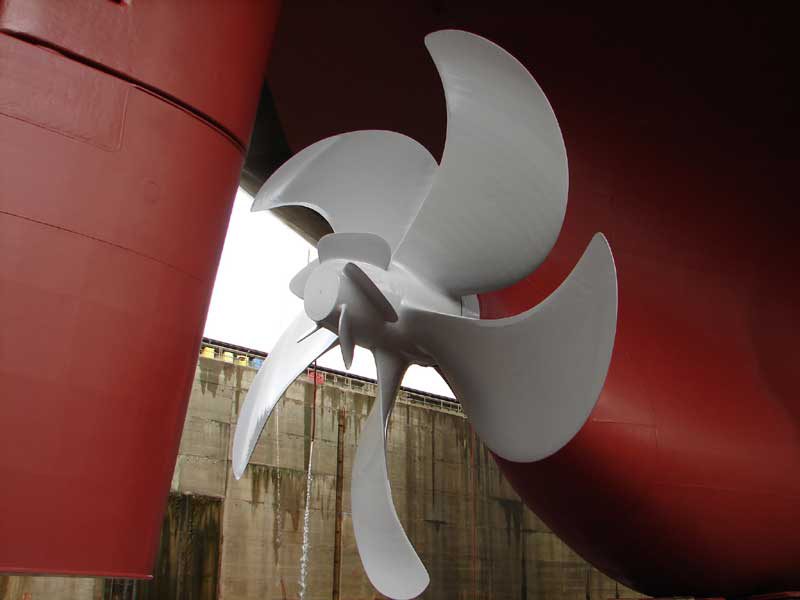

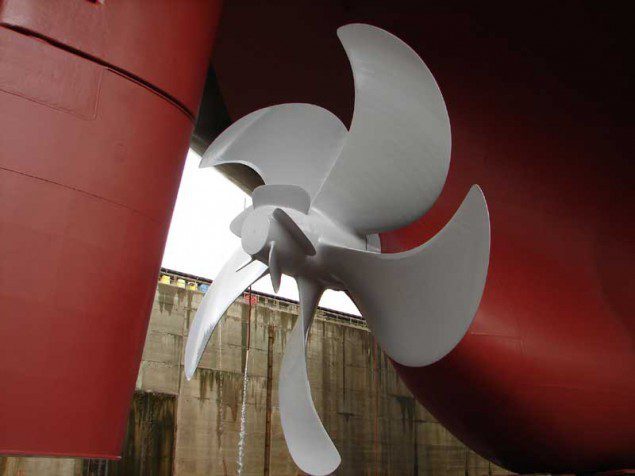

Appendages to the propulsion system at the stern of a vessel can offer ship owners and operators an easy and relatively painless solution to improving fuel efficiency without the need to order new and expensive ‘eco-ships’. With many products offering the prospect of a relatively short return on investment, the path to greater sustainability can be embarked upon sooner rather than later.

The ability to improve propulsive efficiency with mechanisms and devices added in front or astern of the propeller, is currently one of the surest ways to save fuel on a ship; many of the devices are well-developed and tested with extensive in-service data to support the claims and marketing hype of the manufacturers.

Propeller efficiency comes down to simple physics; unfavourable wake flow from the hull into the propeller as well as energy losses from propeller rotation will reduce the potential thrust that can be gained from a propeller functioning in fully optimised conditions. In an effort to counteract this, appendages and supplements to propeller systems have been invented to create the conditions that are most conducive to obtaining maximum thrust from the propeller.

Ducts, fins, nozzles, bulbs and an array of other devices exist to propel vessels at reduced power and faster speeds.

One of the oldest and yet most enduring of propeller appendages, the Kort Nozzle, has proved the inspiration for many of the devices that are available on the market for commercial vessels nowadays. The Kort nozzle was named after its German inventor, Ludwig Kort, who demonstrated in the 1930s that encasing a propeller with a foil-shaped covering could improve propeller efficiency on vessels.

Nowadays , the Kort nozzle is still actively employed on vessels but only those that require high thrust and travel at slow operating speeds, such as tugs and trawlers. This is because the nozzle actually adds drag and at speeds above 10 knots, can negate the additional thrust it provides for the propeller.

However, over the last decade or two, technology has progressed to allow larger commercial vessels, such as tankers and container vessels, to benefit from the science behind the Kort nozzle, which is fundamentally based on accelerating the flow of water into the propeller, thus reducing pressure and propeller thrust.

The Mewis Duct and Wake Equalizing Duct (WED) are two examples of fore-propeller appendages that are based on the essential science of the Kort nozzle but have been adapted for the larger scale commercial vessel.

Since its introduction to the market in 2010, the Mewis Duct has gained attention from ship owners and builders alike; 62 vessels are currently fitted with the Duct with a further 250 on order. One tanker operator in 2011, after seeing power savings of 6% achieved in model tests overseen by MARINTEK, had sufficient confidence in the device to sign a contract for 22 tankers to be fitted with it. Other known ships to have employed the duct are bulkers and container feeder vessels.

Of course, at a time when balance sheets are the primary concern of many businesses, the investment needs to be the right one with a manageable and balanced element of risk attached. With the Mewis Duct, an innovative approach to neutralising this risk has been adopted by Becker Marine to instill confidence in the buyer: the company offers a form of guarantee for the performance of the device by promising a full refund of installation costs and cancellation of contracts if the device does not give fuel savings of at least 4.5%. If such savings are achieved, the ROI is usually one year or less for the device.

For additional understanding of the exact savings that can be achieved with different vessel types, try the CTech fuel savings calculator. A more mature product on the market from the 1980s, Schneekluth’s Wake Equalizing Duct (WED) has seen over 1,500 applications to marine vessels. Also placed to the fore of the propeller with the aim of accelerating water in-flow, it is ideally suited to vessels with full hull forms, such as tankers and containers operating under 19 knots.

Schneekluth confidently advertises an optimum saving of 12%. However, the key to fuel savings claims made by manufacturers is to have them supported by in-service data from ship operators already employing the technologies. The headline 12% saving is primarily based on model tests that were conducted on E3 tankers in the Hamburg Ship Model Basin, HSVA, where an 11.8% reduction was recorded.

Evidence of the savings potential in real-time operation is far lower than this headline figure, with Hamburg Süd documenting fuel savings of 3.5% across four 2,500 TEU vessels fitted with the device. Despite representing a far lower percentage than the optimum saving potential, a 3.5% reduction still signifies a noteworthy annual fuel reduction of 550 tons per ship according to the container shipping company.

Ducts are however not the only devices that can be added in front of a propeller to improve efficiency; DSME’s Pre-Swirl Stator offers an alternative to the water channeling effects of ducts and nozzles.

In development for more than a decade, the Pre-Swirl Stator, which consists of a number of stator blades attached to the boss end of the hull in front of the propeller, actually adds to the ship’s resistance instead of increasing forward thrust. However, the asymmetric swirl generated by the blades creates a more favourable wake in which the propellers can rotate, thereby increasing efficiency.

As with the ducts, the device is especially suitable for the larger hull forms, evident on container and tanker vessels. Its first installation on a 320,000 DWT VLCC, owned by Kristen Tankers who have since been rebranded as Maran, saw fuel consumption reduced by 4% and that with a slight increase in speed as well. A large European container company has also recently embarked on installing the device across its range of 10 post-panamax vessels, and is already noticing reductions in fuel consumption and emissions alike.

The savings details of this and other studies can be found within the Fathom-Ctech database. Register Here.

Equally efficient and cost effective, both in installation and operation, are devices that can be placed to the aft of the propeller. Two of these devices, the Propeller Boss Cap Fin (PBCF) and Propeller Cap Turbine (PCT), can be added to the propeller’s rear in place of the normal boss cap; both perform the identical function of recapturing some of the rotational energy generated by the propeller.

The Propeller Boss Cap Fins consists of small fins attached to the propeller cap whilst the Propeller Cap Turbine (PCT) comprises a number of hydrofoil shaped blades integrally cast into the hub cap.

The PBCF, first developed and manufactured at the end of the 1980s, has had over 2,000 installations worldwide, and is perhaps evidence that the manufacturer’s savings claims of 3-5% are credible. Indeed, one large worldwide tanker company has verified these results with Fathom; they did however note that the PBCF’s effectiveness was reduced at slower steaming speeds.

Along with the fore-propeller appendages available on the market, the PBCF and PCT are relatively low-cost and non-complicated additions to a propulsion system. Indeed the operator that spoke with Fathom stated that the return on investment on the PBCF came within the first year, whilst attachment of the device to the propeller was completed within two days without the need to dry-dock.

So, it is apparent that fuel savings are achievable from the implementation of appropriate yet fairly simple and easy-to-install devices. With the ever increasing cost of bunker fuel, these devices now offer short return-on-investments, firmly establishing their business case.

Without the need to send a fleet to scrap and invest in new eco-design ships feeling their way on to the market, proven propeller appendages, both mature and new, are currently available to help drive costs down and improve the long-term outlook for owners and operators.

The devices mentioned in the article are by no means an exhaustive list of the propulsion enhancers available on the market. For further information on other propeller modifications, appendages, rudder devices and a whole host of fuel-saving technologies and products, membership of Fathom-CTech is available at a monthly rate.

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Stay informed with the latest maritime and offshore news, delivered daily straight to your inbox

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up