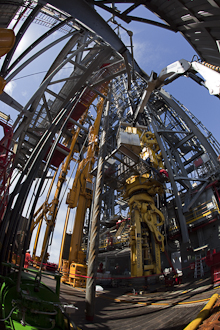

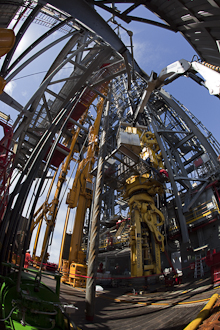

The Bureau of Ocean Energy Management (BOEM), formerly known as the MMS, released two new directives today under an “emergency rule-making process”. Their new “Drilling Safety Rule” and the “Workplace Safety Rule” take a detailed look at offshore drilling operations, from both a technical and an HSE standpoint, respectively.

The Bureau of Ocean Energy Management (BOEM), formerly known as the MMS, released two new directives today under an “emergency rule-making process”. Their new “Drilling Safety Rule” and the “Workplace Safety Rule” take a detailed look at offshore drilling operations, from both a technical and an HSE standpoint, respectively.

In a surprising move, Michael R. Bromwich, director of the BOEM, has opened the floor to public discussion and “will accept and consider public comments submitted within 60 days of the rule’s publication”.

Speaking with DOI Press Secretary Kendra Barkoff, specifics of how the Department of the Interior and BOEM plan to gather this industry commentary will follow in the next few days.

Below is the “Drilling Safety Rule” in it’s entirety. Please feel free to start this commentary on the gCaptain forum and we’ll make sure your feedback is heard.

THE BUREAU OF OCEAN ENERGY MANAGEMENT,

REGULATION AND ENFORCEMENT

Office of Public Affairs

FACT SHEET

THE DRILLING SAFETY RULE

An Interim Final Rule to Enhance Safety Measures for Energy

Development on the Outer Continental Shelf

The Bureau of Ocean Energy Management, Regulation and Enforcement (BOEM) is submitting to the Federal Register for publication the interim final Drilling Safety Rule. The Drilling Safety Rule will be effective immediately upon publication.

The Drilling Safety Rule imposes requirements that will enhance the safety of oil and gas drilling operations on the Outer Continental Shelf (OCS). It addresses both well bore integrity and well control equipment and procedures.

Well bore integrity provides the first line of defense against a blowout by preventing a loss of well control. It includes the appropriate use of drilling fluids and the well bore casing and cementing program. Provisions in the rule addressing well bore integrity are:

- Making mandatory the currently voluntary practices recommended in the American Petroleum Institute’s (API) standard, RP 65 – Part 2, Isolating Potential

- Flow Zones During Well Construction (an industry standard program)

- Requiring submittal of certification by a professional engineer that the casing and cementing program is appropriate for the purposes for which it is intended under expected wellbore pressure

- Requiring two independent test barriers across each flow path during well completion activities (certified by a professional engineer)

- Ensuring proper installation, sealing and locking of the casing or liner

- Requiring approval from the BOEM District Manager before replacing a heavier drilling fluid with a lighter fluid

- Requiring enhanced deepwater well control training for rig personnel.

Well control equipment includes the Blowout Preventer (BOP) and control systems that activate the BOP. Provisions in the rule on well control equipment include:

- Submittal of documentation and schematics for all control systems

- Requirements for independent third party verification that the blind-shear rams are capable of cutting any drill pipe in the hole under maximum anticipated surface pressure

- Requirement for a subsea BOP stack equipped with Remotely Operated Vehicle (ROV) intervention capability (at a minimum the ROV must be capable of closing one set of pipe rams, closing one set of blind-shear rams, and unlatching the Lower Marine Riser Package)

- Requirement for maintaining a ROV and having a trained ROV crew on each floating drilling rig on a continuous basis

- Requirement for auto shear and deadman systems for dynamically positioned rigs

- Establishment of minimum requirements for personnel authorized to operate critical BOP equipment

- Requirement for documentation of subsea BOP inspections and maintenance according to API RP 53, Recommended Practices for Blowout Prevention Equipment Systems for Drilling Wells

- Require testing of all ROV intervention functions on subsea BOP stack during stump test and testing at least one set of rams in initial seafloor test

- Require function testing auto shear and deadman systems on the subsea BOP stack during the stump test and testing the deadman system during the initial test on the seafloor

- Require pressure testing if any shear rams are used in an emergency.

This Drilling Safety Rule is issued under an emergency rulemaking process consistent with Administrative Procedure Act (APA) requirements. The equipment, systems and improved practices stipulated in the rule are immediately necessary for the safety of OCS oil and gas drilling operations and the protection of the environment.

While the rule is effective immediately upon publication, BOEM will accept and consider public comments submitted within 60 days of the rule’s publication. The agency will then either publish a new rule with modifications in light of comments received or publish a notice that will confirm the rule as final with no additional changes.

This rule is based upon recommendations contained in Secretary Salazar’s May 27th, 2010, Safety Measures Report to the President and codifies ongoing requirements of Notice to Lessees No. 2010-N05 (NTL 5).

BOEM intends to address additional provisions considered appropriate in light of the Deepwater Horizon explosion in additional rulemakings in the coming months.

Join The Club

Join The Club

The Bureau of Ocean Energy Management (BOEM), formerly known as the MMS, released two new directives today under an “emergency rule-making process”. Their new “Drilling Safety Rule” and the “Workplace Safety Rule” take a detailed look at offshore drilling operations, from both a technical and an HSE standpoint, respectively.

The Bureau of Ocean Energy Management (BOEM), formerly known as the MMS, released two new directives today under an “emergency rule-making process”. Their new “Drilling Safety Rule” and the “Workplace Safety Rule” take a detailed look at offshore drilling operations, from both a technical and an HSE standpoint, respectively.