In Part 2 of this series on shipping efficiency technology, we look at new ship propulsion technologies and design concepts aimed at cutting operating costs, while at the same time reducing ship emissions. (Source: Wärtsilä)

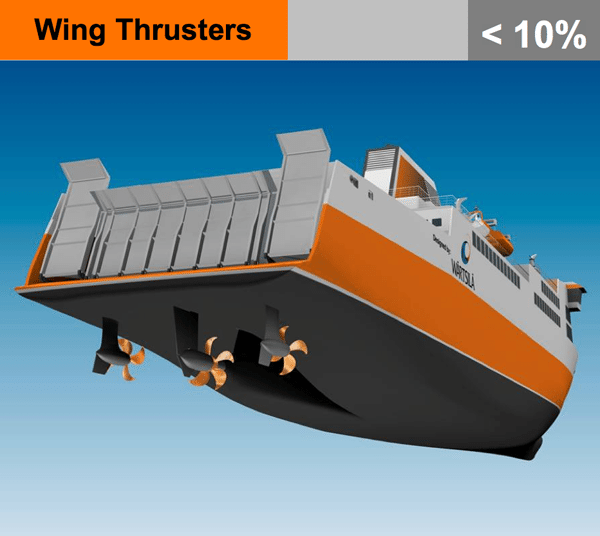

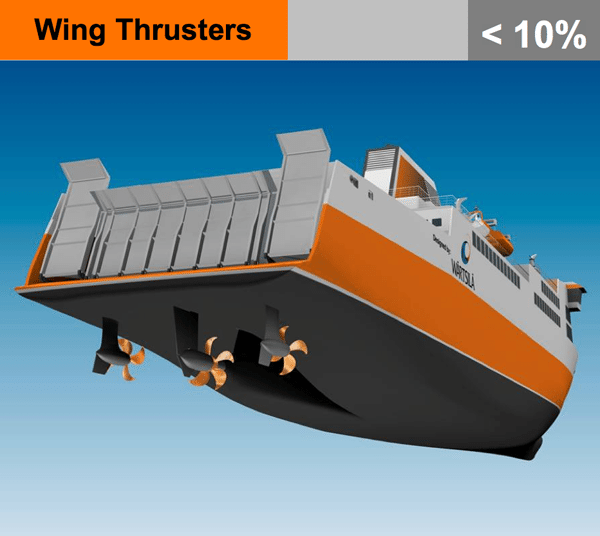

Installing wing thrusters on twin screw vessels can achieve significant power savings, obtained mainly due to lower resistance from the hull appendages.

The propulsion concept compares a centre line propeller and two wing thrusters with a twin shaft line arrangement.

Result: Better ship performance in the range of 8% to 10%. More flexibility in the engine arrangement and more competitive ship performance.

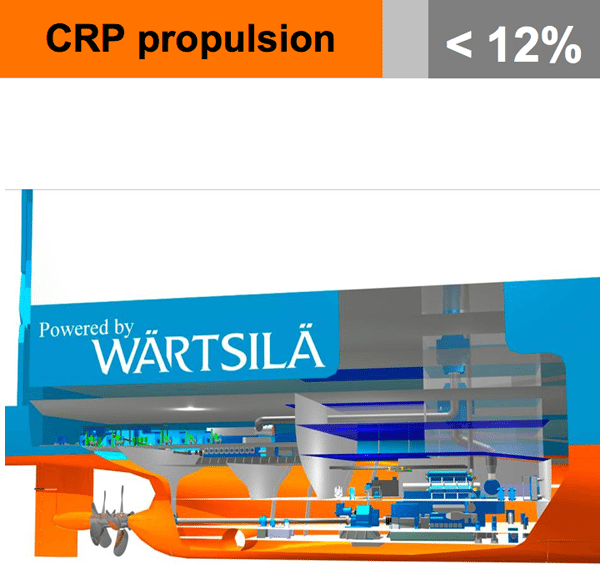

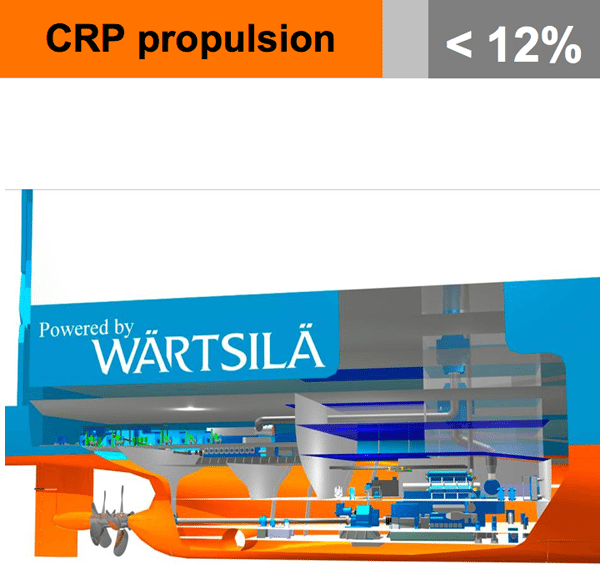

Counter rotating propellers consist of a pair of propellers behind each other that rotate in opposite directions. The aft propeller recovers some of the rotational energy in the slipstream from the forward propeller. The propeller couple also gives lower propeller loading than for a single propeller resulting in better efficiency.

CRP propellers can either be mounted on twin coaxial counter rotating shafts or the aft propeller can be located on a steerable propulsor aft of a conventional shaft line.

CRP has been documented as the propulsor with one of the highest efficiencies. The power reduction for a single screw vessel is 10% to 15%.

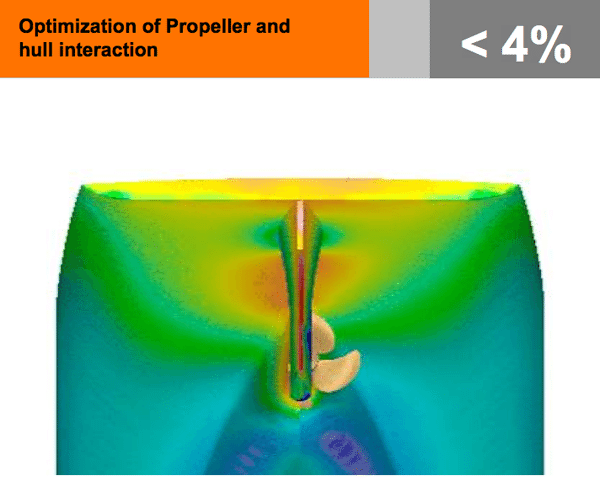

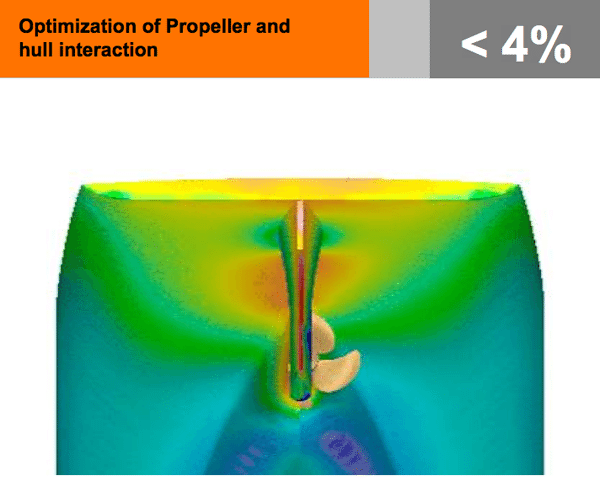

The propeller and the ship interact. The acceleration of water due to propeller action can have a negative effect on the resistance of the ship or appendages. This effect can today be predicted and analyzed more accurately using computational techniques.

Redesigning the hull, appendages and propeller together will at low cost improve performance by up to 4%.

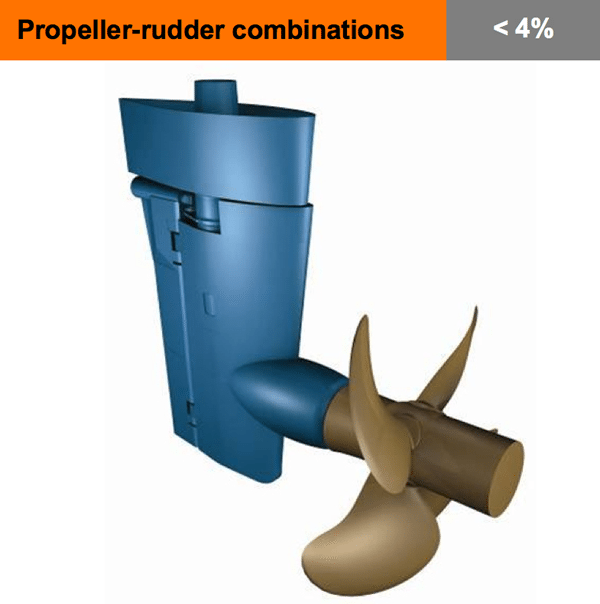

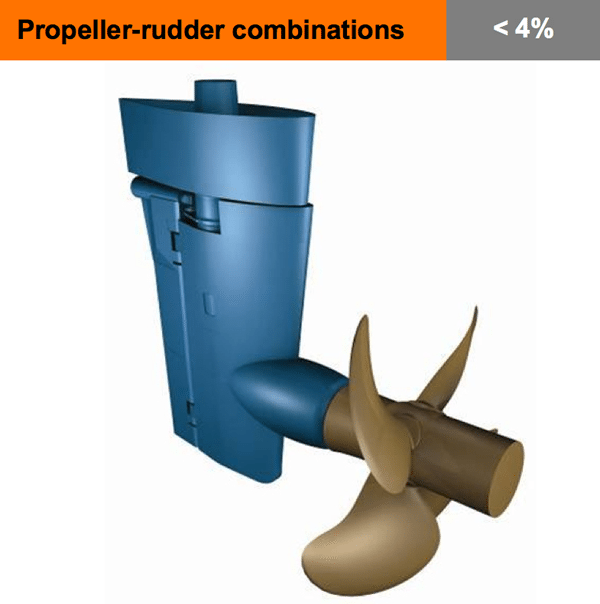

The rudder has drag in the order of 5% of ship resistance. This can be reduced by 50% by changing the rudder profile and the propeller. Designing these together with a rudder bulb will give additional benefits.

Improved fuel efficiency of 2% to 6%.

Advanced blade sections will improve the cavitation performance and frictional resistance of a propeller blade. As a result the propeller is more efficient.

Improved propeller efficiency of up to 2%.

Winglets are known from the aircraft industry. The design of special tip shapes can now be based on computational fluid dynamic calculations which will improve propeller efficiency.

Improved propeller efficiency of up to 4%.

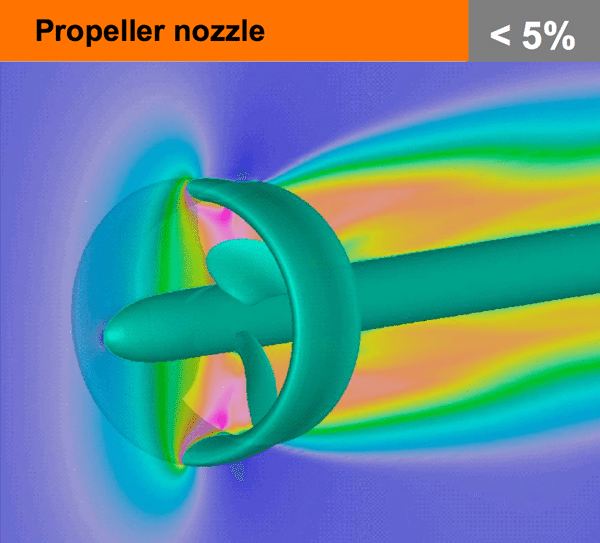

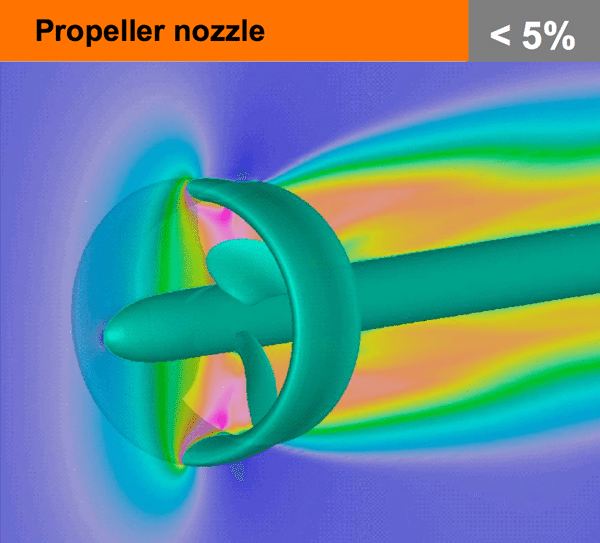

Installing nozzles shaped like a wing section around a propeller will save fuel for ship speeds of up to 20 knots.

Up to 5% power savings compared to a vessel with an open propeller.

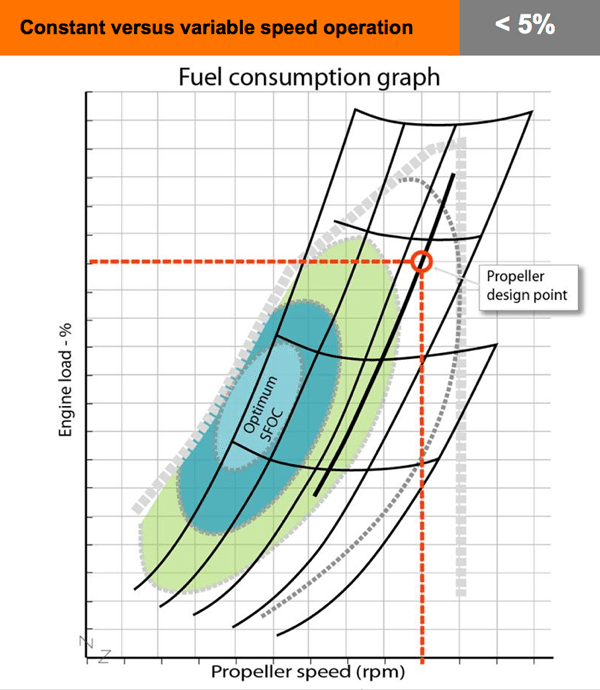

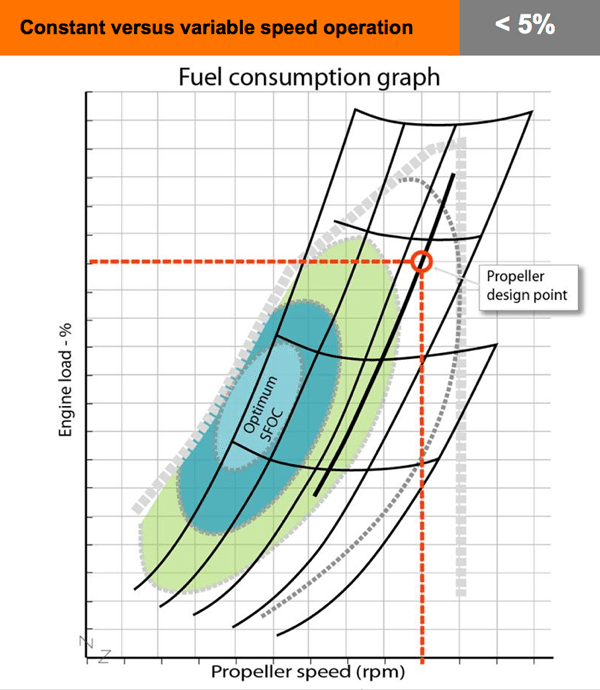

For controllable pitch propellers, operation at a constant number of revolutions over a wide ship speed reduces efficiency. Reduction of the number of revolutions at reduced ship speed will give fuel savings.

Saves 5% fuel, depending on actual operating conditions.

Wing-shaped sails installed on the deck or a kite attached to the bow of the ship use wind energy for added forward thrust. Static sails made of composite material and fabric sails are possible.

Fuel consumption savings:

- Tanker ~ 21%

- PCTC ~20%

- Ferry ~8.5%

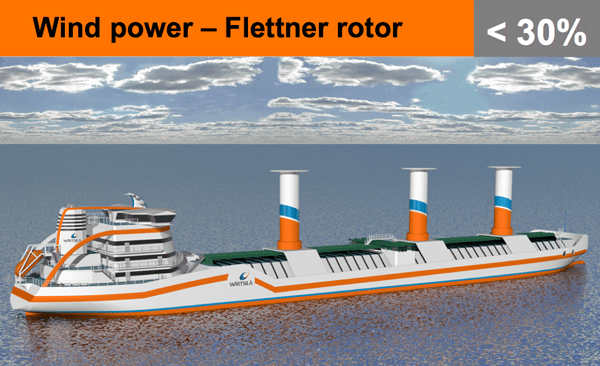

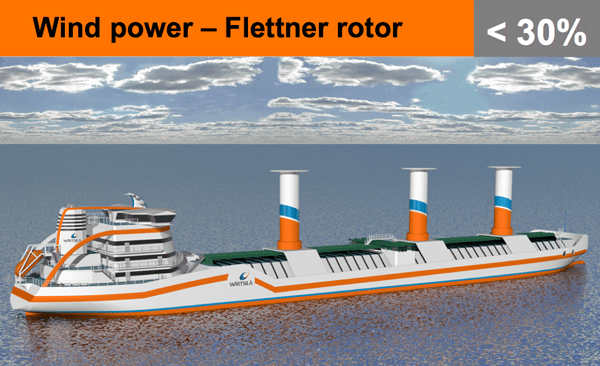

Spinning vertical (Flettner) rotors installed on the ship convert wind power into thrust in the perpendicular direction of the wind, utilising the Magnus effect. This means that in side wind conditions the ship will benefit from the added thrust.

Less propulsion power is required, resulting in lower fuel consumption.

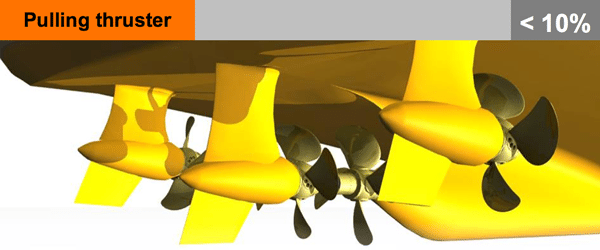

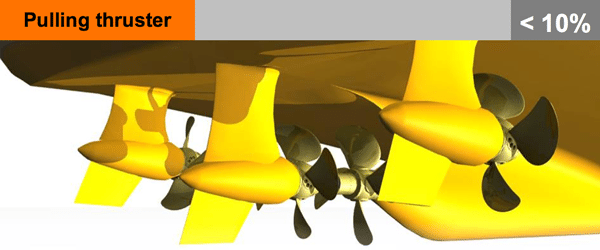

Steerable thrusters with a pulling propeller can give clear power savings. The pulling thrusters can be combined in different setups. They can be favorably combined with a centre shaft on the centre line skeg in either a CRP or a Wing Thruster configuration. Even a combination of both options can give great benefits. The lower power demand arises from less appendage resistance than a twin shaft solution and the high propulsion efficiencies of the propulsors with a clean waterflow inflow.

The propulsion power demand at the propellers can be reduced by up to 15% with pulling thrusters in advanced setups.

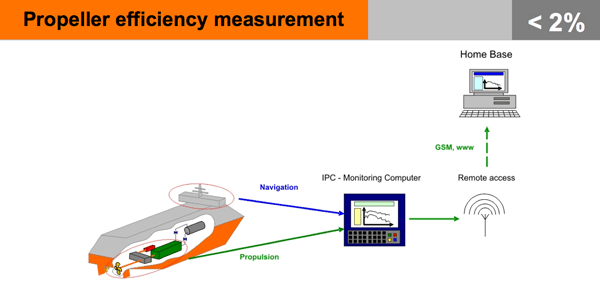

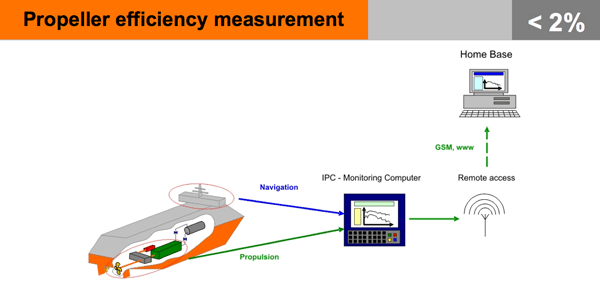

Measure performance data on board to save fuel. The measurements taken will include propeller performance data such as speed through the water, propeller torque and propeller thrust.

Accurate measurement of propeller data will enable fuel savings in operation. Experience shows that this can reduce fuel consumption by as much as 4%.

In Part 3, we’ll be taking a look at technology related to the ship’s machinery systems…

Unlock Exclusive Insights Today!

Join the gCaptain Club for curated content, insider opinions, and vibrant community discussions.

Join The Club

Join The Club