Indian Navy Battles Engine Room Fire on Tanker in Gulf of Oman

The Indian Navy stealth frigate INS Tabar has responded to a distress call from the Pulau-flagged tanker MT Yi Cheng 6 in the Gulf of Oman on Sunday after the...

The damaged James T. Wilson fishing pier with debris on the deck of the barge is depicted in this photo taken Nov. 17, 2019. Photo Credit: U.S. Coast Guard

The failure of a weld ultimately led to a barge breaking loose from its mooring and heavily damaging a pier in Hampton, Virginia, the National Transportation Safety Board said in a Marine Accident Brief issued Thursday

The incident occurred November 17, 2019. when sometime before sunrise, a construction barge broke free from its mooring in stormy weather and drifted about two miles to the south before it contacted and damaged an entertainment pier and grounded on a beach just north of a fishing pier in Hampton, Virginia.

Emergency responders were notified but were unable to stop the barge’s continued movement down the beach where it ultimately contacted the James T. Wilson fishing pier. The contact caused two of the pier’s forty-foot concrete spans to collapse, according to facts presented in the Marine Accident Brief.

Nobody was aboard the barge or on the pier when the accident occurred. No one was injured in the accident, which resulted in more than a million dollars of damage to the pier and about $38,000 to the barge.

“The National Transportation Safety Board determines that the probable cause of the contact between the barge YD 71 and the James T. Wilson Fishing Pier was a shackle pin in the mooring arrangement working itself free in heavy weather, leading to the barge’s uncontrolled drift,” the NTSB stated as the probable cause.

The NTSB describes the mooring arrangement in the excerpt below:

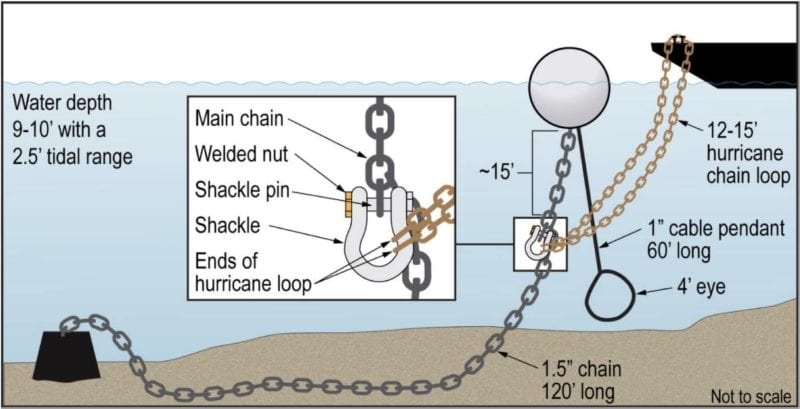

Coastal Design & Construction Inc. owned several moorings located approximately 800 feet offshore and just north and outside of the channel to the Salt Ponds. Each mooring consisted of a 4,500–5,000 pound anchor weight, 120 feet of 1.5-inch chain, and a mooring ball. Barges were moored to the bottom chain with a 60-foot-long, 1-inch cable pendant with a 4-foot eye. The eye was typically looped over the forward bitts on the barge. Additionally, each mooring had a 12- to 15-foot loop of chain, called a hurricane loop, that was shackled through one link of the bottom chain. The mooring was set in 9 to 10 feet of water, with a hard, sandy bottom, and a tidal range of 2.5 feet. The mooring pre-dated the construction project but was inspected and found satisfactory in August 2019 for this work.

The hurricane loop was shackled to the bottom chain 15 feet below the mooring ball. The shackle’s crown was passed through each bitter end of the hurricane loop. The shackle pin was passed through a link at the bottom chain with the center stud removed and held in place with a nut. The nut was welded to the shackle pin, all the way around to keep it from backing out.

The eight-page Marine Accident Brief 20-35 is available here.

NTSB accident reports in all modes of transportation can now be accessed through CAROL, the NTSB’s new accident investigation search tool: https://go.usa.gov/x7Rnj.

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Stay informed with the latest maritime and offshore news, delivered daily straight to your inbox

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up