Major Cocaine Bust: UK Border Force Seizes Record Shipment at London Gateway

In one of the UK’s largest drug seizures of the past decade, UK Border Force officers have seized cocaine with an estimated street value of £96 million (USD 130 million)...

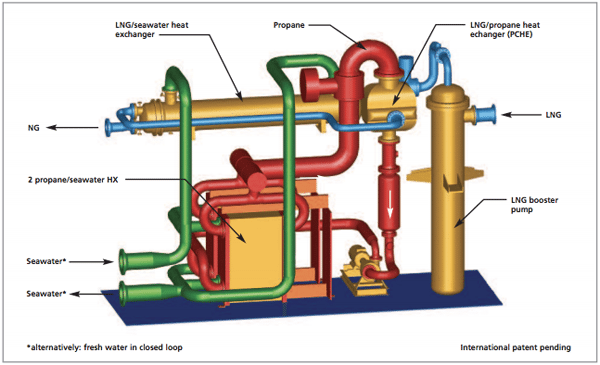

Hamworthy’s regas module at Sinopacific, image courtesy Hamworthy

Hamworthy Oil & Gas Systems has secured a contract to supply its innovative LNG regasification technology for the third Hoegh LNG Floating Storage and Regasification Unit (FSRU) under construction at Hyundai Heavy Industries.

Here’s how it works:

Via Hamworthy:

In this system, LNG is heated by propane in a closed loop and the propane is heated by seawater. In situations where the seawater is too cold to supply all the required heating energy, additional heat can be introduced.

The cascade concept is recommended instead of directly heat exchanging with seawater. LNG heat exchanged directly with seawater increases the risk of freezing the seawater in the heat exchanger. Propane as a secondary medium is suggested because of its thermodynamic properties with a low freezing point.

A HAZID analysis has been carried out with DNV to identify risks related to the design and operation of the regasification system. For example, it was concluded that the cascade system is a safer system than the pure seawater based. LNG enters a cryogenic pump capable of producing the required send-out pressure (e.g. up to 130 bar has been studied). LNG at the required discharge pressure is heated in two stages.

In the first stage LNG is heated from -160°C to -10°C in a compact printed circuit heat exchanger with propane as a heating medium.

In the second stage, LNG can be heated further using seawater as a heating medium in a shell and tube heat

exchanger.In the LNG/Propane heat exchanger, heat is exchanged against propane circulating in a closed loop. The propane enters the heat exchanger at approx. 0°C at 4.7 bar as gas. In the heat exchanging process propane is condensed, and leaves the exchanger in a liquid state at approximately -5°C. The propane in the closed loop is then pumped by the circulating pump and heated against seawater in titanium semi welded plate heat exchangers. In these heat exchangers, the propane is evaporated and heated to 0°C before returning as gas to the printed circuit heat exchanger.

Working together with Sinopacific Offshore and Engineering (SOE), Wartsila Hamworthy will design and supply the system concept whilst the key equipment and fabrication will be supplied by SOE.

This partnership agreement follows on from the contract to supply a propane-seawater regasification system for the first two 170,000m3 capacity vessels signed in November last year.

The floating regasification market is experiencing significant uptake and Höegh have projected annual growth in the LNG market of 6-7% over the coming few years.

Sveinung Støhle, Hoegh LNG’s President and Chief Executive, was quoted as saying: “Our strategy to expand in the floating regasification market worldwide remains firm and we believe in strong continued growth in this segment.”

Reidar Strande, LNG Business Unit Director, Hamworthy Oil and Gas Systems said: “This contract for Hoegh LNG follows on from the joint project with SOE in supplying our regasification module for the converted Golar Khannur. The module concept was a fast-track project allowing the regasification system to be almost complete before lifting onboard the vessel, with very few interfaces. Delivery of this equipment took place in November 2011.”

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Stay informed with the latest maritime and offshore news, delivered daily straight to your inbox

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up