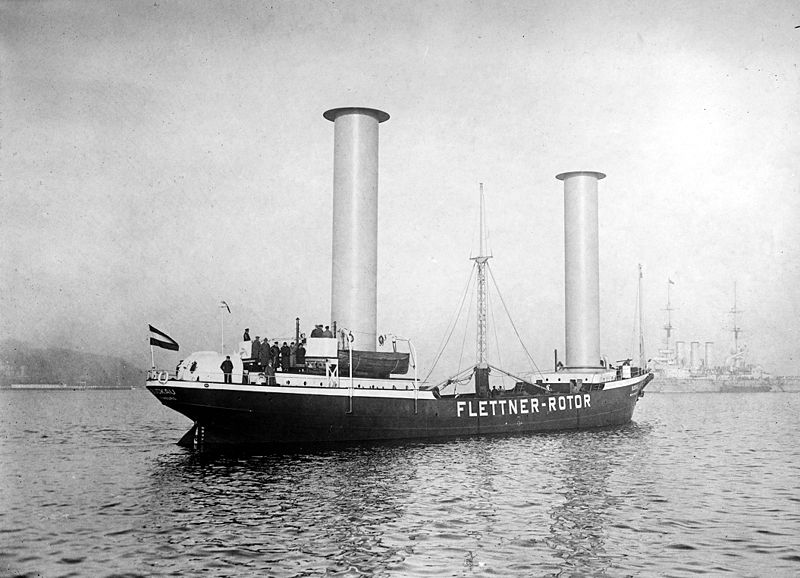

Buckau, the first ship to use Flettner rotors, via Library of Congress

In February 1925, the Buckau, a schooner outfitted with cylindrically-shaped, rotating masts 15 meters tall and 3 meters in diameter, crossed the North Sea from Danzig to Scotland to prove the concept of using the Magnus Effect to propel a vessel at sea.

The system was designed by German engineer Anton Flettner and the concept was proven valid.

Over the years however, diesel propulsion took hold and Flettner’s concept never took hold on the global merchant shipping scene.

Fast forward 90 years and the idea is now being reborn amid high bunker prices and a highly competitive commercial shipping landscape.

Over the past three years, Switzerland-based company Thiiink has evolved the Flettner rotor concept with support from partners Lloyd’s Register (LR), and a group of European engineering companies including – Airbus, Huisman, Constellium, Schaeffler, Bosch, Liebherr and Walter Hunger – and an oil major, which, according to Thiiink CEO Jorn Winkler, “has agreed to do long-term charters for vessels with rotors installed.”

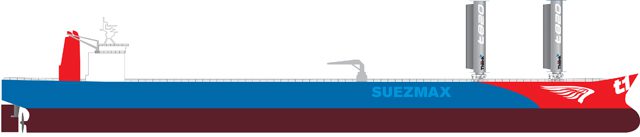

The initial plan, according to a report today by Lloyd’s Register, is to install two, 47-meter tall Flettner rotors, each with a sail flap attached, on board an LR2 product tanker or Suezmax in 2015.

While utilizing this system on 110,000 dwt tanker during a transatlantic voyage from the Cabot Strait off the coast of eastern Canada to the English Channel, the added thrust from the Flettner rotors could potentially reduce a vessel’s main engine output by around 28% according to Thiiink. Further calculations show that the main engine output can be reduced by almost 40% if voyage planning is optimized in accordance with the Flettner rotors effect.

When it comes to achieving the most out of this technology, there are a lot of new variables that come into play however.

With wind angles on the beam of the ship, the rotors will generate a significant amount of forward thrust, however this will result in a narrower angle of attack on the vessel’s propeller blades, in turn making them less efficient. If a vessel has a controllable pitch system, the optimized pitch and revolutions of the propeller blades while using the rotors in different wind conditions and directions would have to be considered with any vessel routing solution.

If the vessel which is to be retrofitted is using a fixed pitch propeller, the efficiency gains would certainly still be positive while using such a system, however not as positive as they could be if the blade angles themselves could be optimized while underway.

In addition, the lateral force created on the bow by the rotors would have a direct affect on the rudder angle needed to keep the vessel sailing in a straight line. The greater the angle needed, the more drag created, thus reducing the overall potential efficiency gains.

Furthermore, forecasted winds and wind angles based on voyage plans are only as good as the data provided. Even when coupled with highly sophisticated software, someone still needs to make the “tactical” decision of where to turn the ship given a multitude of possible options based on what may or may not happen with the weather and currents. As any offshore yachtsman can tell you, the right decision is hardly ever clear.

LR notes the spinning cylinders will be software-controlled by the bridge watchstanders and be hydraulically folded onto the vessel’s deck during adverse weather conditions or while entering port, but for the UK-based classification society, their involvement is not necessarily about the efficiency gains from the rotors themselves.

“LR’s approach to the classification of Flettner rotors is based on the understanding that the rotors themselves are not essential for the safe operation of the ship. If they are to be installed on an LR classed ship, LR needs to be satisfied that they would not adversely affect the safe operation of the ship or the safety of its crew either during normal operation of the rotors or following failure,” commented Darshana Godaliyadde, Project Lead and Specialist of LR Marine, Engineering Systems.

Join The Club

Join The Club