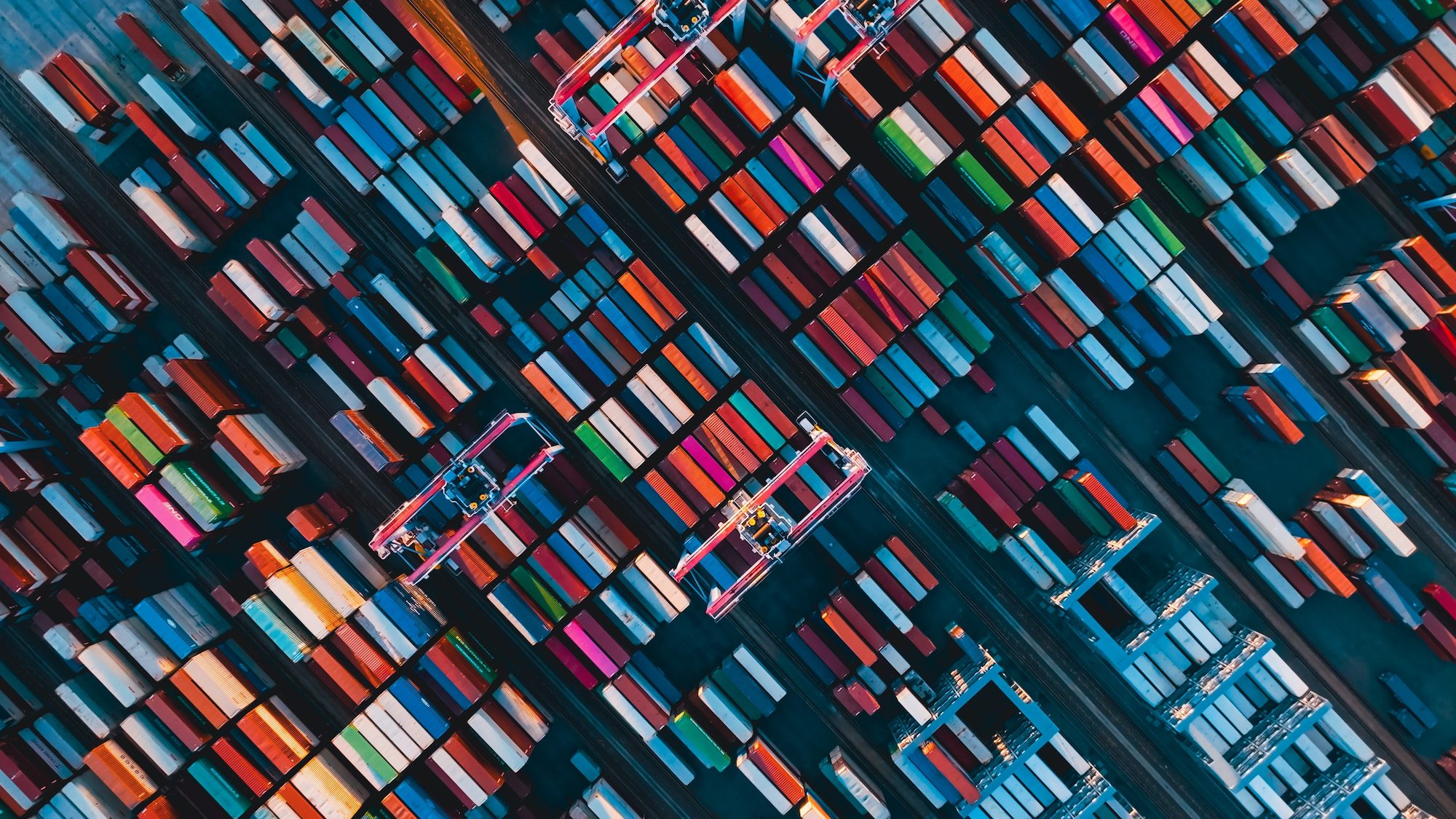

With the specter of renewed Trump-era tariffs looming large over global supply chains, industries are already strategizing how to shield their supply chains from potential disruption.

President-Elect Donald Trump has pledged to impose blanket tariffs of up to 20% on all imports into the U.S., with an even more stringent 60% to 100% tariff on goods from China.

Moody’s Senior Director of Supply Chain Strategy, John Donigian, warns of the possible “resurgence of the Trump administration’s previous approach to tariffs,” highlighting the likelihood of increased duties on imports from key manufacturing countries. This shift could usher in a new era of complexity for supply chains, compounding existing challenges wrought by post-pandemic disruptions and geopolitical tensions.

The impact of such tariffs would be far-reaching, with Donigian noting, “For global supply chains, this scenario would mean higher costs, potential delays, and pressure for businesses to reconsider sourcing strategies.”

Donigian warns that industries particularly vulnerable to these anticipated changes include electronics, automotive, retail, and pharmaceuticals, with each sector facing unique challenges. Electronics and technology firms may face slow and costly production shifts due to their complex global sourcing needs, while the automotive industry, heavily reliant on global parts suppliers, could experience significant cost increases and delays. Retail and consumer goods sectors also might see impacts on consumer prices and inventory levels. Lastly, pharmaceutical and medical device companies could struggle with regulatory standards and quality control when relocating production.

In response, companies may be compelled to pivot their supply networks, potentially shifting production closer to North America or even repatriating manufacturing to the United States.

To navigate these turbulent waters, Donigian outlines several mitigation strategies, advising companies to “diversify suppliers across regions, implement dual sourcing strategies, and build strategic inventory buffers.”

Donigian also suggests leveraging “free trade zones, bonded warehouses, and duty drawback programs” to offset tariff costs. For companies considering reshoring, investments in automation and innovative manufacturing technologies could help balance higher labor costs.

As businesses brace for potential changes, Donigian emphasizes the importance of cross-functional planning to ensure alignment between procurement, logistics, and risk management teams. This holistic approach may be crucial for effectively navigating the complex challenges posed by shifting trade policies and their impact on global supply chains.

As companies reevaluate their supply chain strategies, expect in the coming months to see a significant reshaping of global manufacturing and distribution networks.

Join The Club

Join The Club