South Africa’s Transnet, Union in Talks to Avoid Strike

(Bloomberg) — The biggest labor union at South Africa’s state-owned port and rail company are starting final talks with a third-party arbitrator to resolve a wage dispute and stave off...

Graphic representation of the Nautic wetfish trawler design, courtesy of HB Grandi/Nautic)

Three new wetfish trawlers ordered last August by Icelandic fishing company HB Grandi will feature a full MAN Diesel & Turbo propulsion system including 6-cylinder L27/38 main engines, four-bladed, 3.8-meter, ducted Alpha VBS 860 propellers and a SCR (Selective Catalytic Reduction) system to enable compliance with IMO Tier III NOx emission requirements.

The three vessels are under construction at Celictrans Deniz Ltd., a Turkish shipyard that is also in the process of building two pelagic fishing vessels for HB Grandi due for delivery this year.

Vilhjalmur Vilhjalmsson, CEO of HB Grandi said: “When we decided to renew our fresh-fish fleet, we immediately focused on the task of curtailing the ships’ power requirements, both in terms of the propulsion plant as well as electricity production, so as to make the exhaust gas as clean as possible.”

Nautic – based in Reykjavi?k – is designing the new vessels, which will replace three wetfish trawlers currently in service. The vessels are scheduled for delivery in May 2016, late-2016 and spring 2017, respectively.

Propulsion package characteristics

The new HB Grandi wetfish trawlers will enjoy the benefit of several features to optimise operation. These include employing a floating-frequency concept that increases their flexibility and economical part-load pattern with an up to 17% lower engine/propeller speed and a commensurately lower fuel consumption.

MAN Diesel & Turbo’s new, advanced Alphatronic 3000 generation propulsion-control system will also be installed aboard the trawlers and, among other characteristics, features tailored ‘dual-propeller load curves’ for optimizing towing/trawling and free-sailing conditions.

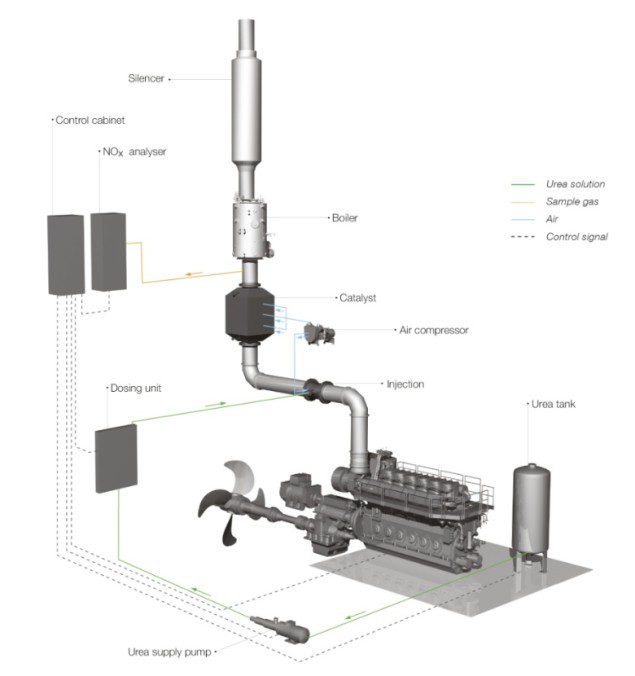

Selective Catalytic Reduction

SCR is the most tested and approved system for achieving NOx reduction rates up of to 90%. SCR involves the injection of ammonia or urea, into the diesel engine’s exhaust stream. The urea decomposes into ammonia and carbon dioxide, with the ammonia subsequently reacting with NOx and oxygen in the presence of a catalyst, transforming into the ecologically-benign constituents of water and nitrogen.

In order to optimise the SCR process at part load, the engine is specified with a turbocharger bypass as part of the exhaust gas temperature system that ensures sufficiently high temperatures.

SCR plant description

MAN Diesel & Turbo’s SCR system is available in fourteen different sizes, in this way fully covering its entire portfolio of medium-speed engines. The system has been devised as a modular kit of components for reasons of simplicity and to minimise costs.

A special feature of the system is its communication with the engine control system that optimises the temperature for the SCR system at individual load- points.

A further special feature of the system is its continuous NOx-emission control that saves urea and avoids ammonia slip.

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Stay informed with the latest maritime and offshore news, delivered daily straight to your inbox

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up