Indian Seafarers Freed After Months of Detention at Yemen’s Ras Isa Port

India says it has secured the release of more than 150 seafarers who were stranded at Yemen’s Ras Isa Port, according to the Directorate General of Shipping. All 11 vessels...

Construction of the world’s largest ship is picking up speed. Recently, the very first propeller was loaded onto the Maersk Salalah container ship in Hamburg bound for the DSME shipyard in Okpo, South Korea. The shipyard will build all 20 of the Triple-E vessels, the first to be delivered in July 2013.

Construction of the world’s largest ship is picking up speed. Recently, the very first propeller was loaded onto the Maersk Salalah container ship in Hamburg bound for the DSME shipyard in Okpo, South Korea. The shipyard will build all 20 of the Triple-E vessels, the first to be delivered in July 2013.

With a diameter of 10m and a weight of about 70 tons, the giant, four-bladed propeller for the first Triple-E was loaded onto Maersk Salalah. Two of these propellers will provide the thrust for the 400-meter-long Triple-E’s.

With a diameter of 10m and a weight of about 70 tons, the giant, four-bladed propeller for the first Triple-E was loaded onto Maersk Salalah. Two of these propellers will provide the thrust for the 400-meter-long Triple-E’s.

Instead of one large six-blade propeller, like the one seen on the left in the photo, research at Maersk Maritime Technology has concluded that the Triple-E’s will be more energy efficient with two four-bladed propellers.

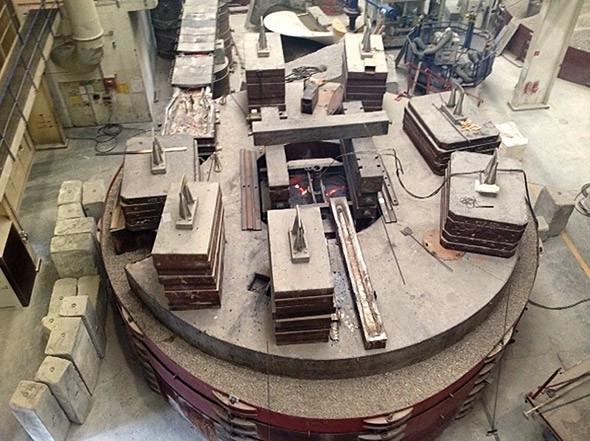

Manufactured by Mecklenburger Metallguss GmbH (MMG) in Germany, the propellers are cast in moulds with 500 tonnes of weight placed on top to counter the buoyancy of alloy as hot as 1,190-degree Celsius.

Manufactured by Mecklenburger Metallguss GmbH (MMG) in Germany, the propellers are cast in moulds with 500 tonnes of weight placed on top to counter the buoyancy of alloy as hot as 1,190-degree Celsius.

At MMG, the liners and bushings are created in a process called centrifugal casting whereby the molten material is casted in a fast rotating cylindrical die. The released centrifugal force generates a pressure on the liquid metal which is approximately 30 times higher than under normal gravity conditions.

The metal is forced centrifugally to outside until the directional solidification of the metal progresses from the outside toward the bore. The result is a defect-free structure of the cylindrical casting. In comparison with other casting methods, the mechanical properties are improved by same chemical composition of the alloy.

The outer diameter is determined by the particular die; the inner diameter by the quantity of the casting material.

The cast of the propellers take just 10 minutes. Then they have to cool for 10 days.

The cast of the propellers take just 10 minutes. Then they have to cool for 10 days.

Maersk Salalah will deliver the first propeller to the Daewoo Ship Manufacturing & Engineering shipyard in Okpo, Korea, in mid-November.

– via Maersk Line

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Stay informed with the latest maritime and offshore news, delivered daily straight to your inbox

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up