Shedding Light on “Hot Work” Safety Gaps Offshore

On a relatively mild November morning, a fire broke out on an oil platform about 12 miles off the Louisiana coast, sending a column of black smoke into the sky....

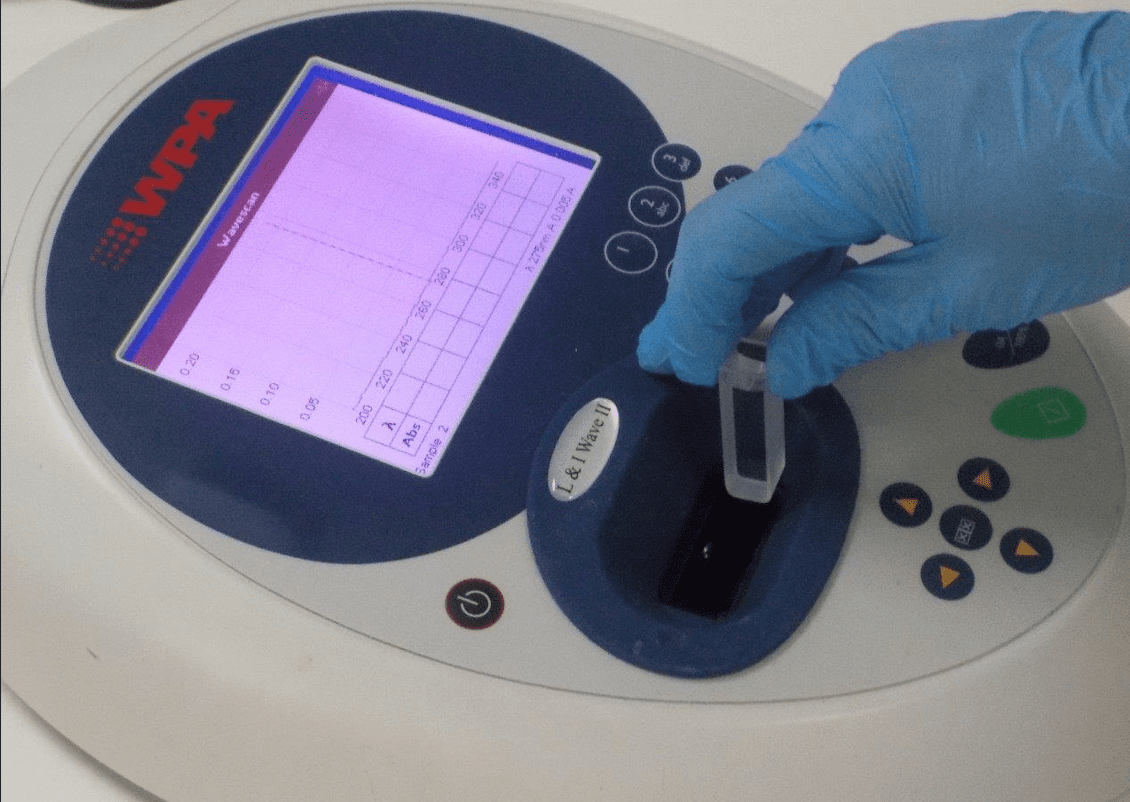

MOL Chemical Tankers has equipped its operating vessels with spectrophotometer that allow seafarers to monitor tank cleaning operations at any time in the process, without having to enter the confined spaces of the cargo tanks. It has seen strong interest from Charterers in its plugged-in ‘washing water analysis’ process, jointly developed with a chemical consultancy, which has proven superior to traditional wall wash inspection.

Chemical carriage as a highly specialised operation requires constant monitoring and testing of tank condition prior to loading, specifications for which Charterer’s supply data based on the long-accepted Wall Wash Test.

Historically, chemical tankers are inspected by third-party surveyors prior to loading the next nominated cargo, and in many cases that involves tank entry and the taking of wall wash samples to determine cargo tank suitability. The sampling involves “washing” a small area of the tank to remove any residual contaminants and Surveyors (and ship’s crew during the cleaning operation) must enter each tank to carry out this testing.

Given the tanks must meet wall wash specifications prior to arrival at a loading port, seafarers are required to make multiple confined space entries during each tank cleaning operation.

“Confined space entry has accounted for a number of fatalities on board tankers in past years. We have achieved the reduction of enclosed and confined space entry by shifting the focus of the testing from condition on the bulkhead to the condition of the wash water. We are absolutely committed to minimise this risk in the future.” said Dorte Creaven, General Manager, MOL Chemical Tankers Europe A/S.

This way of monitoring tank cleaning operations is known as Wash Water Analysis and the process utilizes a spectrophotometer that uses ultraviolet light to measure the absorption by contaminants in a wash water sample.

Another advantage of Wash Water Analysis is that it is possible to monitor the tank cleaning process Live during the actual cleaning.

With this, the actual washing of tanks can be reduced by a measurement of the wash water rather than a fixed time of Tank Cleaning and physical inspection prior to moving to the next phase.

Captain Martin Hislop, Global Marine Leader, MOL Chemical Tankers Europe A/S points out: “The very act of having to pass a wall wash inspection can lead to over-cleaning of vessels, which is proven to significantly increase environmental impact in terms of:

Furthermore, the washing water analysis process ensures greater accuracy of the whole cleaning status, including that in the entire tank and the line which is not the case for the traditional methods.

With this process in use Charterers can see the benefits of the vessel being cleaned to a high level of certainty with clear evidence enabling self- certification of the Tank Clean Certificate. Vessels can then arrive at the loading berth with the tanks fully pre-approved and, if required, inerted which removes a level of personnel exposure, proves an environmental benefit in reduced time at berth as well as allowing terminal planning to achieve a greater throughput of vessels.

“Both Charterers and Operators are able to have a much better flexibility in the port and a much better port turn-around as it is not required to wait for the 3rd party surveyor to take the wall wash test, get same analysed in the lab and await the result which sometimes can take up to 8-12 hours.” Ms. Creaven said.

The list of MOLCT’s customers includes many of the largest chemical suppliers in the world, which have their own KPI’s relating to safety, sustainability, and environmental impact, all of which are positively impacted by the washing water analysis process.

Ms. Creaven commented: “Our objective for the remainder of 2022 is to invite all of our customers to join us on our safety journey. Our goal is to work with responsible Partners/Customers who place safety and environmental impact at the fore front of chemical transportation. We are committed to achieving the Environmental Vision established for the entire MOL Group and when we can get all our customers onboard with accepting the washing water data instead of the wall wash test, we will be able to minimize our CO2 emissions substantially.”

“We can benefit from using our experienced officers and crew’s competences and knowledge to self-certify the tanks instead of having to accept a 3rd party surveyor to decide whether the cargo tanks are ready for loading, as we have up to 50 years of knowledge and experience in cleaning tanks onboard the vessels within the officers and crew onboard our vessels.” Captain Hislop said.

And a final comment from Captain Hislop and Ms. Creaven:

“We want our customers to do business with MOLCT because they trust our name and recognise that our expertise ensures we will meet and exceed all of their expectations, at the same time always safeguarding the welfare of our seafarers, so that they can come home to their families when their work is done.”

“The most positive endorsement of this (washing water analysis) initiative has so far come from our customers, many of whom have already adopted Wash Water Analysis replacing the wall wash inspection, and in so doing, have successfully loaded and discharged significant volumes of high purity chemical cargoes.”

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up