World’s Biggest Ship Lift Opens in China

Officials in China have began testing the world’s largest ship lift at the massive Three Gorges Dam in Central China. The shiplift can lift vessels up to 3,000 tons across...

Classification society ClassNK and Nakashima Propeller Co. this week announced the world’s first installation of a carbon fiber reinforced plastic (CFRP) propeller on the main propulsion system of a merchant vessel.

The CFRP propeller, which was manufactured by Nakashima Propeller, was installed in May on the Taiko Maru, a domestic 499 GT chemical tanker owned by Sowa Kaiun YK at the Marugame-based Koa industry Co. in Japan. The propeller was manufactured with support from ClassNK, which granted approval for the design and manufacturing process, as well as provided research and funding support as part of the ClassNK Joint R&D for Industry Program.

Research and development on the use CFRP propellers was supported by the Nippon Foundation and the Japan Ship Machinery & Equipment Association (JSMEA) from 2007 to 2011, followed by a joint research project carried out in 2012 by Nakashima Propeller Co., Ltd, the University of Tokyo School of Engineering, Japan’s National Maritime Research Institute (NMRI), NYK Line, MTI Co., Ltd., Imabari Shipbuilding Co., Ltd, and ClassNK as part of ClassNK’s Joint R&D for Industry program.

The research found that CFRP exhibits the same, if not superior strength to the aluminum-bronze composite materials used in conventional propellers. Due to its ultra-light weight however, propeller shafts can be manufactured with smaller diameters, contributing to a significant reduction in weight and fuel costs.

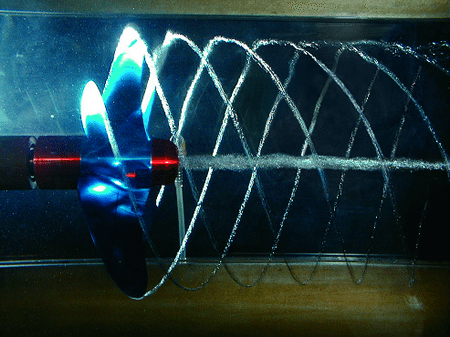

The sturdy yet thin blades of the CFRP have been designed with an increased diameter similar to the wings of a Boeing 787 aircraft, ClassNK said in a statement. This should allow CFRP propellers to achieve even greater efficiency when employed for maritime use and the potential for further performance improvements continues to be explored via testing model tank testing.

The Taiko Maru had already previously installed CFRP propellers in its side thrusters in September 2012. Based on the successful performance, Sowa Kaiun YK made the decision to extend use of the CFRP propeller technology to its main propulsion system, making the vessel the first in the world to use a CFRP for its main propulsion system.

During sea trials the CFRP required 9% less horsepower to operate compared to conventional aluminum-bronze propellers, and expansion of their use on merchant vessels is expected to contribute to better fuel economy and greater efficiency in operations, according to ClassNk and Nakashima.

As part of the testing, ClassNK carried out rigorous fatigue testing and material testing to assess the basic mechanical properties of the propeller, as well as conducted static load testing on full-scale propeller blades to determine the adaptability of the propeller for marine-use prior to approving the CFRP propeller for use as part of the merchant vessel’s main propulsion system,

ClassNK also carefully evaluated the manufacturing process and quality control systems for the 2.12m diameter CFRP, and expert ClassNK surveyors further assessed mechanical properties and results of stress analysis tests for each component during the vessel’s construction, as well as verified the installation of the system during construction.

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up