By vrihu / Shutterstock

By Michael Carr – I worked at bracing myself under the ship, trying to steady my body against the hull while inserting the foam lance’s fabric-covered tip into the icebreaker’s sea chest. Adding air to my Unisuit pressed me against the hull. I held the 5 ft long foam lance with both hands, with legs spread and finally found a stable position.

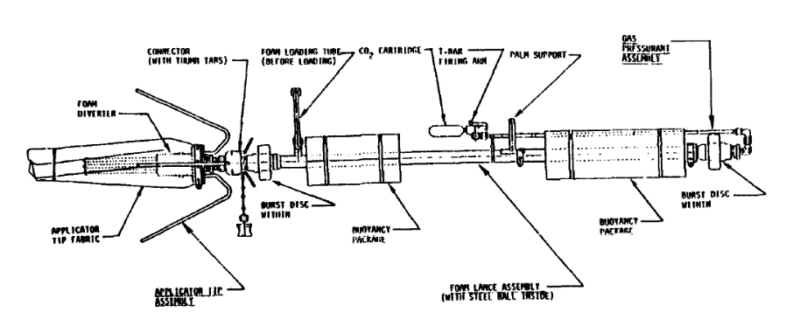

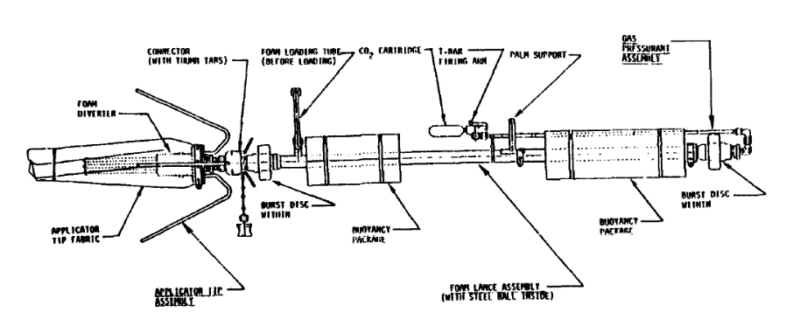

Now I could “pull the trigger” on the lance and inflate the foam plug. It was not really a trigger but a lever which punctures a high-volume CO2 cylinder. And then, as best described in the lance’s operations manual:

“… feeding carbon dioxide gas through a gas expansion tube into the rear of the lance, at this point the rear rupture disc breaks and pressurant gas enters, driving a chrome steel ball against the pressurized foam mix, when the pressure gains 300 psi the front rupture disc gives way and the polystyrene foam exists the lance, and a polystyrene matrix forms, expanding and forming a solid ball… “

This explosive process takes less than 2 seconds. You activate the lever and there is a BAM and WHOOSH and the solid polystyrene ball is formed. It conforms to the shape of the hole and becomes immediately solid and unmoving.

You have one shot, one trigger pull to get this correct. I was not, at this moment, thinking about the chemistry and science behind the lance, but instead focused on getting the lance’s bag lined up correctly in the ice breaker’s sea chest.

We had only one lance. The Coast Guard 140 ft icebreaker needed to open its sea chest and repair cracked welds from inside the ship. The Chesapeake Bay was covered in ice, this winter was exceptionally cold, and ice extended from the northernmost C & D Canal, all the way south to Norfolk VA.

“Send your divers to Yorktown VA, we need you to plug the ice breaker’s sea chest so they can repair cracks and get back to breaking ice”. That was the mission we received. Figure it out, get it done.

We could have gone with a standard outside hard patch but trying to fit a patch to the icebreakers curved hull would have been time-consuming and difficult. Working in freezing conditions, with air and water temperatures below freezing would really challenge our abilities.

We elected to try using the foam lance. One shot, but if we did it correctly the lance would seal the sea chest and repairs could be done that day. The lance had never been used in freezing conditions. It might not inflate. We called the Coast Guard Research and Development Center.

“Do you think it will inflate in freezing conditions?”

“Wow, good question. It should, but it might inflate slower. We recommend you pull the activation lever as fast as possible. Let that gas pressure increase quickly.”

So here I was under the icebreaker, shivering in my drysuit, holding the lance with two mitt covered hands. Very little dexterity, ice forming around me, and trying to keep the lance perpendicular to the ship’s hull.

“One shot, one kill,” I thought. Line up the lance, push it against the hull, pull the lever, don’t hesitate. Steady breathing.

BAM, WHOOSH, BANG. I pulled the lever, the CO2 shot into the lance, the polystyrene bag inflated. I waited, then poked the bag, it was hard as a rock. I checked the edges of the sea chest; the foam bag overlapped the edges. Popping the kamlock fittings on the foam plug I removed the lance and gently attempted to wiggle the plug. Was it really holding? It did not move; it’s expanded foam and water pressure holding it in place.

“Damn,” I thought, “I think its holding”.

Inside the icebreaker engineers removed the sea chest cover and found it dry. Welding commenced to repair cracks caused by vibrations due to nearly continuous icebreaking operations. We took a break on the ship’s mess deck drinking coffee and warming up.

Within a few hours, the cracks were welded. “You can take the plug out now” came the word from the ship’s engineer.

Down we went under the ship, and after a fair amount of wiggling, banging, cutting and cursing we remove the plug, which immediately shot to the surface once free of the sea chest opening.

We then stood on the dock and watched the ice breaker steam out into the York River, heading back to breaking the ice.

“I love those guys at the R & D Center, we need to order more foam lances!” and I sure am glad that foam expanded!

Join The Club

Join The Club