When joining a new vessel as a DP operator it is important to look at the most recent FMEA in order to better understand the vessels capabilities, as well as its restrictions.

But what exactly is an FMEA & how was it developed?

What is an FMEA?

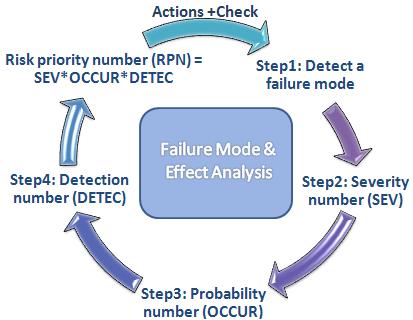

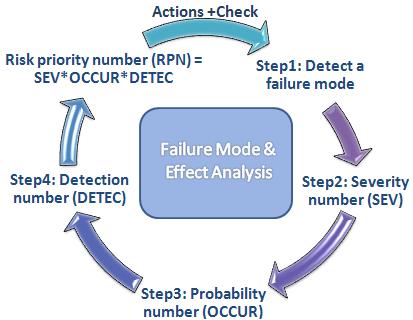

Learning from each failure can be costly & time consuming. FMEA is a systematic method of studying failure. This ensures that time is not wasted & the root of the problem is quickly determined. It is used to Identify methods to eliminate or reduce the chance of that failure occuring in the future.

It should be noted that an FMEA is a Living Document that is used to anticipate & prevent failures from occuring. As such it must be continuously updated as changes in the system occur.

FMEA stands for Failure Mode Effect Analysis. Failure Mode is defined as the manner by which a failure is observed. It describes the way the failure occurs.

FMEA trials will be conducted onboard a DP vessel by a competent third party, working with the ships crew, whenever a major change has taken place. An example would be a thruster overhaul in dry dock. It should also be updated whenever:

â–ª At the beginning of a cycle (new product/process)

â–ª Changes are made to the operating conditions

â–ª A change is made in the design

â–ª New regulations are instituted

â–ª Customer feedback indicates a problem

History

The FMEA discipline was developed in the United States Military. Military Procedure MIL-P-1629, titled Procedures for Performing a Failure Mode, Effects and Criticality Analysis, is dated November 9, 1949. It was used as a reliability evaluation technique to determine the effect of system and equipment failures. Failures were classified according to their impact on mission success and personnel/equipment safety.

Later it was used in the aerospace industry to avoid errors in small sample sizes of costly rocket technology. The Apollo Space program is an example.

Then in the 70’s it was introduced to the automotive industry by the Ford Motor Company.

DNV & ABS adopted the requirement for FMEA in the late 1970’s – early 1980’s.

The Process

Over the vessels life it will undergo a number of FMEA’s, each with diffeen requirements.

1. As the vessel is designed, the processes & components undergo an initial Design FMEA

2. The vessel is brought into service & the FMEA is proofed.

3. That FMEA is built upon as the vessels early trials & experiences are integrated.

4. As a mature working vessel, the FMEA only needs to be updated when major changes have taken place.

Objectives

A Failure Modes and Effects Analysis (FMEA) is required by class for any Dynamically Positioned (DP) vessel for Class 2 or Class 3.

The objective of an FMEA, as applied to a DP vessel, should be to provide a comprehensive, systematic and documented analysis to establish the important failure modes with regard to station keeping. The analysis must seek to determine any failure modes that can affect the station keeping as a whole and cause a position loss. The possible modes of position loss are:

• Drive off

• Drift off

• Large excursion

The analysis seeks to find any single point failure in any of the total DP system that can cause any of the position losses stated. The FMEA of a DP vessel is based on a single failure concept under which each system’s subsystems and parts are assumed to fail by one probable cause at a time. It must in effect make sure that the stated worse case failure for the vessel cannot be exceeded by any single failure.

It is also customary to include a single act of mal operation as a possible single failure. This is assessed when a mistake is easy to make due to system layout where a single act has severe consequences. ‘Single act’ is a subjective definition and is generally taken to mean the operation of a single button, lever or switch.

The analysis must also consider hidden failures; this is a failure of a back up or standby without an alarm so that a second failure is not realized until the initiating single failure has occurred. For instance a standby pump being faulty; or a UPS having a faulty battery and being unable to take load when required. It must also consider that on some vessels that are in continuous operation, such as drilling vessels, will have some equipment may be down for maintenance for long periods of time.

Scope

The DP system onboard ship includes all compontents required to support & keep the vessel on position. Each of these must be covered in an FMEA, as a failure could come from any sector.

Areas to be addressed include:

- DP Control System

- DP PRS

- Power Management & Distribution

- Thrusters & Propulsion

- Human Factors.

The Human Factor

The inclusion of the Human Factors is interesting, but that can be taken as a single point failure as well. This can be addressed in the FMEA but looking at:

- Capability Plots

- Vessel Footprint

- Communication Systems

- Operator Training & Competance

- Operator Experience

- Working Conditions

- Checklists

- Operations Manuals

- Standing Orders

A Tool for New Joiners

Looking at the vessels most recent FMEA can aid a new joiner to a vessel in quickly getting up to speed on its capabilities & limitations. By identifying the potential problem areas & noting the areas that perhaps have been addressed but not yet rectified, the operator will gain an nderstanding of how that vessel operates.

A Tool for Old Hands

With the ever increasing reliability of shipboard systems (due in large part to the FMEA process), the only time many personnel will see a major failure with the DP system is when it is simulated during FMEA testing. This makes it an essential part of the training process for ships crew.

Join The Club

Join The Club