Iranian Ship Linked to Houthi Attacks Heads Home Amid Tensions

(Bloomberg) — An Iranian ship that’s been linked to Houthi attacks in the Red Sea is returning home, removing a prominent asset in the area as the Islamic Republic braces...

Scanned from RADM Smith’s scrapbook of his trip aboard the dirigible Graf Zeppelin over the Arctic in 1931. Photo via USCG.mil

[contextly_sidebar id=”MhI7lwjN4axzYF31JodkPBp13Okmt2wh”]100 years ago, when “aeroplanes” were an interesting new invention, the age of the Zeppelin was taking off from Friedrichshafen, a quaint village along the shores of Lake Constance in southern Germany.

In that day and age, the term shipyard had to be qualified as Friedrichshafen was home to an airship-yard, with hangars large enough to fully enclose a hydrogen-filled Zeppelin 128-meters in length.

These “ships” were high technology for the day, requiring innovations in lightweight, yet strong construction and bespoke engines and transmissions. With few suppliers available to support this new industry, airship pioneer Ferdinand von Zeppelin founded Luftschiffbau Zeppelin GmbH, from which a number of companies spawned. This included engine manufacturer Luftfahrzeug-Motorenbau GmbH in 1908 and gear manufacturer Zahnradfabrik in 1915. These two companies were led by Wilhelm and Karl Maybach and Max Maag, respectively, and later evolved to become MTU (Motoren- und Turbinen-Union) and ZF Group.

MTU is perhaps a more familiar name for those in the maritime and offshore industry as it reflects the brand name of the power system aboard thousands of ships worldwide, however attached to nearly every MTU engine is a gear box made by ZF.

In fact, attached to tens of thousands of ship engines, car engines, wind turbines, trains and countless other industrial applications worldwide are gearboxes by ZF. Upon a visit to their headquarters last week in Friedrichshafen I found out the company employs over 71,000 people worldwide with over 18.4 billion euros in sales last year. In May, the company acquired US-based TRW Automotive adding bringing roughly 60,000 new employees and 12 billion euros in additional turnover under the ZF brand.

Surprisingly, Wilfried Meichle, Key Account Manager Sales within ZF’s Marine Propulsion Systems group notes that their marine sector business provides only about one percent of the turnover within ZF Group. This includes their portfolio of azimuth and tunnel thrusters, transmissions, fixed pitch propellers and electronic control systems.

In North America, ZF holds the top market share of azimuth thrusters, however these are primarily targeted for tugs, pushboats and hybrid power applications of up to 5,000 horsepower notes Meichle. The offshore support sector is largely above those horsepower ratings.

Worldwide, 19,800 ships operate with ZF transmissions coupled to any number of different engines including MTU (now Rolls-Royce), Caterpillar, Doosan, Wartsila, MAN and others.

Here’s an inside look at where some of those transmissions and gears are built:

Above, raw materials come in from the foundry and are subsequently machined into whatever gear configuration is required by the client, however the process does not end there.

Next, the gears needs to be quenched in an oil bath and CO2-filled atmosphere in order to increase the hardness of the material to roughly 62 Rockwell.

Once the material is hardened, further tweaking is needed to ensure each gear is perfect. ZF notes that only microns of material is taken off the face of each gear at this stage, but it makes the critical difference between a noisy transmission and one that functions silently and effortlessly.

Materials such as the shafts pictured below are only hardened to around 40 Rockwell.

A milled and polished shaft is precisely gauged to ensure it is exactly the right size.

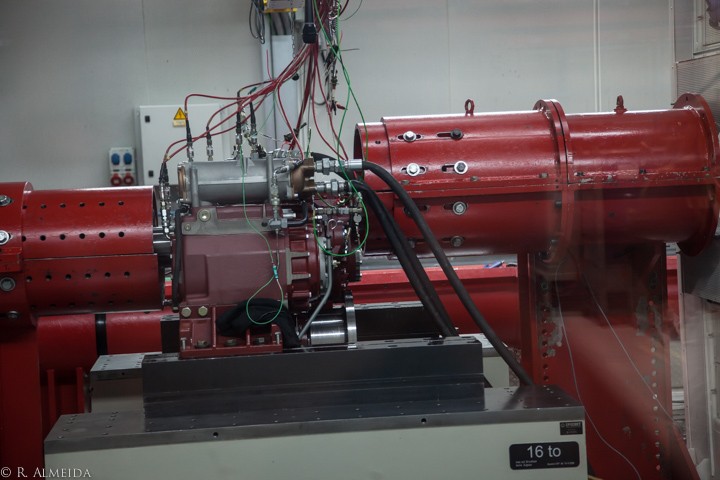

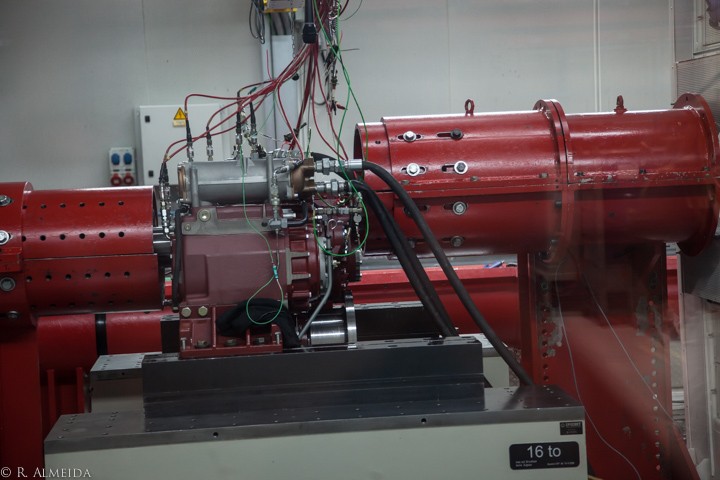

After assembly, the transmissions are tested thoroughly to ensure minimal vibration and noise. In the facility pictured below, the entire room is isolated on an air cushion from the rest of the building to ensure any vibration or noise as a result of the test is due to the transmission itself and not the surrounding environment.

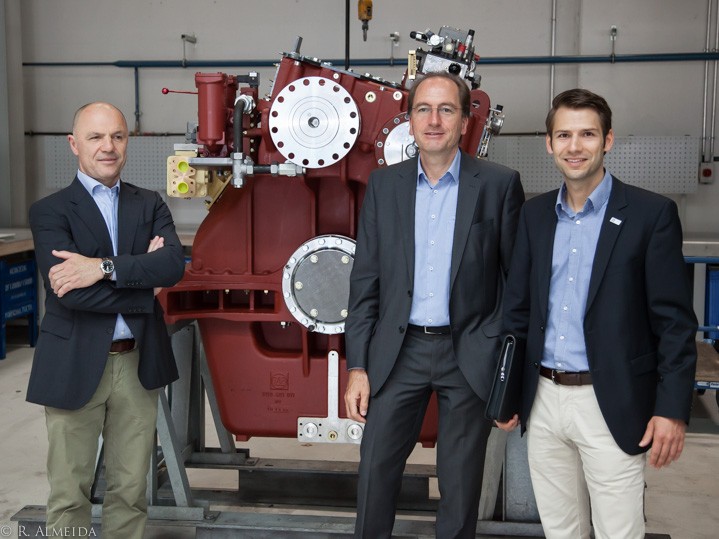

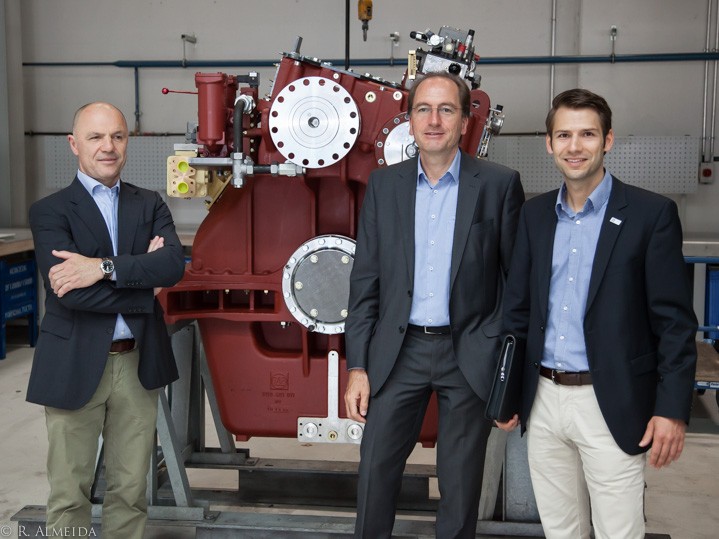

Completed transmissions await shipment to the client (below)

From ZF’s first beginnings 100 years ago building planetary gear systems for air ships, to today’s ultra modern transmissions for high horsepower applications, the company’s distintive trademark has found itself on millions of transmissions around the world. The ZF brand is unique in many respects to others in this industry in that it has managed to keep its footing throughout the challenges of the past century and a devastating world war to perfect what it originally set out to do.

Join the gCaptain Club for curated content, insider opinions, and vibrant community discussions.

Join the 105,960 members that receive our newsletter.

Have a news tip? Let us know.

Access exclusive insights, engage in vibrant discussions, and gain perspectives from our CEO.

Sign Up

Maritime and offshore news trusted by our 105,960 members delivered daily straight to your inbox.

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up