Stena Immaculate Sold for Repairs After Fatal North Sea Collision

Stena Bulk has announced that the oil tanker Stena Immaculate has been sold to a buyer who will undertake repairs at Desan Shipyard. Prior to the transfer, the vessel was...

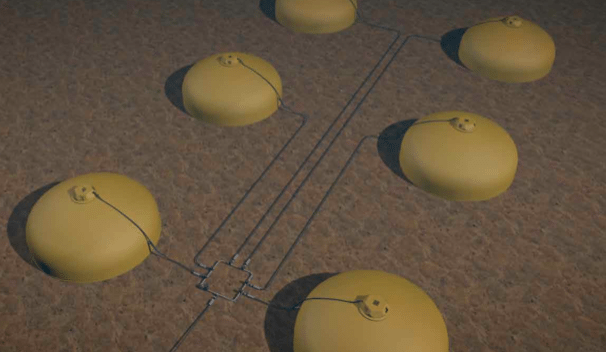

Fuel bladder in Afghanistan, image via Kongsberg

For the past nine years or so, the U.S. Army has been using giant bladders to store the fuel needed to run their vehicles in Afghanistan. Exposed to the elements day and night they are still in good condition according to rubber and plastics specialist ContiTech.

The concept of storing fuel in giant bladders has recently caught the attention of the offshore oil and gas industry, particularly Kongsberg, Statoil, Lundin, Det Norske and the Norwegian Research Council.

When offshore oil and gas fields are created, the produced oil has to be delivered to shore either via pipeline or to some sort of floating storage facility like an FPSO.

Considering the surface of the sea can be quite hostile from a corrosion and fatigue standpoint and people are needed to man these facilities, as well as the ever-present risk of collision at sea, engineers are pondering the question, “why does this storage facility need to float?”

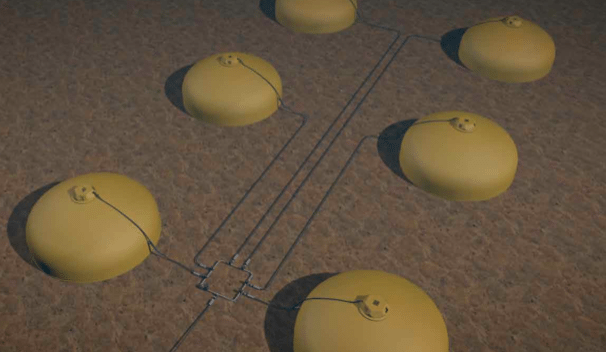

In a presentation today in Houston, Kongsberg notes they have been doing some looking into this and are working on a new concept involving a “Flexible Subsea Storage Unit” where processed crude oil from a subsea oilwell is routed to a giant, 125,000 barrel bladder on the seafloor, protected inside a 30 meter tall dome.

Kongsberg notes this new system would be largely maintenance-free and be completely unaffected by the weather or surface ice conditions found in the arctic. In addition, the dome that protects and houses the collapsable bladder would include an integrated leak detection system and because it would be open to the pressure of the surrounding seawater, there would be no issues with regard to hydrostatic pressures at depth.

Additionally, because there would be no oil/water interaction, there would be no emulsification layer formed.

Once filled, a buoy would then be used to transfer the crude from the unit to a tanker as shown in the following image:

In a conversation with DNV GL Executive Vice President Arthur Stoddart he notes that this concept, although interesting, will likely not be for everyone.

He brings up the point that in some areas, the conditions of the seafloor may not be conducive for such a storage facility and he also notes that such a system would absolutely have to work at all times with little to no maintenance.

Perhaps its possible that one day such a type of storage facility will replace FPSOs as a means to store hydrocarbons from a producing well before being transferred to a ship. For now however, the engineers at Kongsberg as well as their industry colleagues are working to perfect the concept.

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up