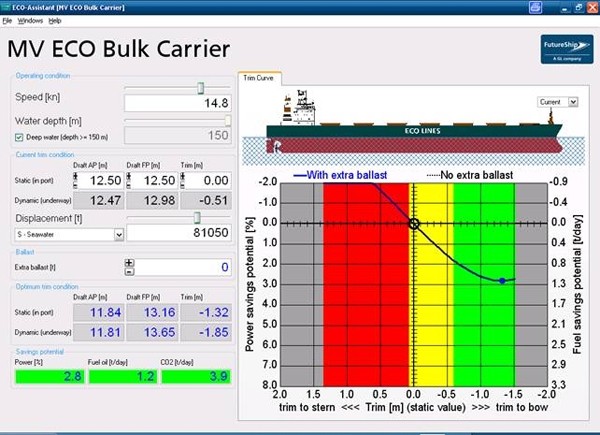

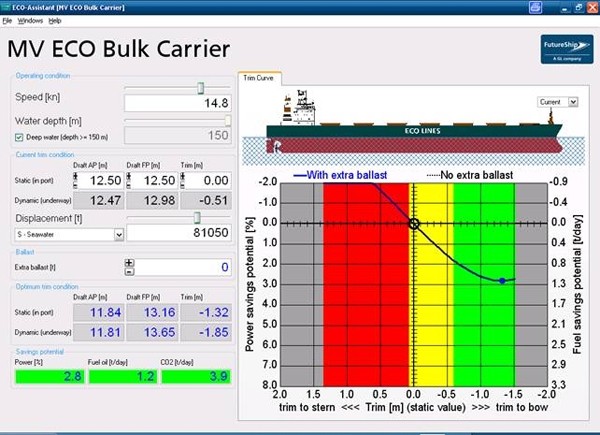

A screen shot of Germanischer Lloyd’s Eco-Assistant, a tool to help ship captains maximize the fuel and power efficiency of their vessels.

In times of increasing fuel prices and environmental awareness the fuel efficiency of ships is becoming more and more important. Computational Fluid Dynamics (CFD) provide a powerful tool to predict the behavior of a vessel in situations such as loading in waves, maneuverability or resistance.

The main use of these tools has, to date, has been during the design phase of vessels. Today, however, advanced applications are bringing these applications on board ships, where CFD models using pre-calculated results can be used to find the optimum trim and draft of the vessel or to predict ship motions.For newly built ships it is becoming essential to optimise fuel efficiency wherever possible to ensure competitiveness in the market. Even for existing ships, modifications to increase fuel efficiency can have short payback periods.Such modifications can include, for example, modernisation of the main engine to increase its fuel efficiency, or replacing the bulbous bow with a new shape to reduce resistance for slow steaming operation. Although the payback period for such modifications might be short, capital investment is required to realise the modifications.Another option is to increase fuel efficiency without modifications to the vessel by increasing operational efficiency, an approach requiring much less capital investment. Operational efficiency has many aspects which can be investigated to reduce fuel consumption.

One such aspect is to help the crew to sail their vessel at optimum trim for the current operating condition. The influence of trim on fuel consumption has been known for quite some time (an example of such an optimisation tool is ECO-Assistant from Futureship).

There is no global optimum trim for a vessel, however. Besides the specific hull shape, the optimum value depends on the operating parameters, such as speed, displacement and water depth.

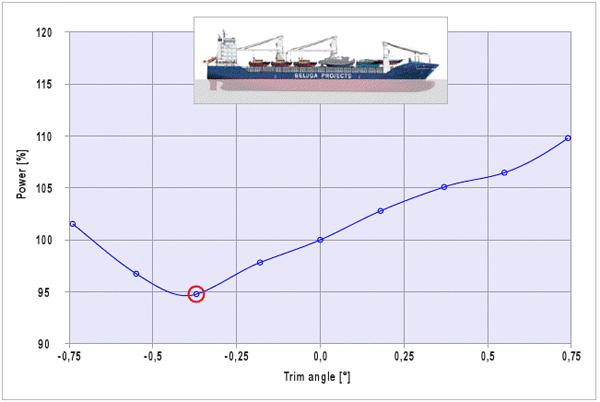

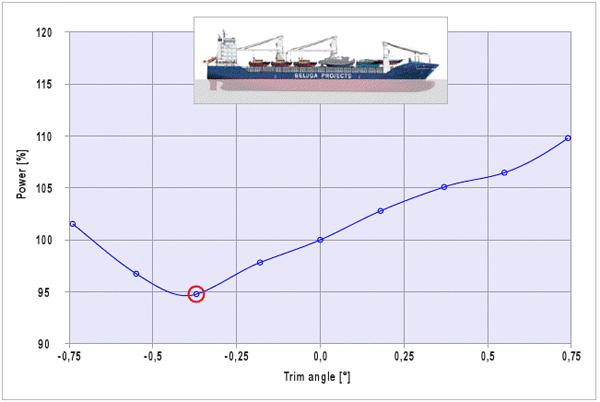

The diagram shows the required power to achieve the target vessel speed for different trim angles in one specific operating condition. For the investigated trim angles between -0.75° and 0.75° the required power varies by 15%. The optimum trim for this condition is -0.4°, which results in a power reduction of 5% compared to level trim. Take, for example, a 5,100 TEU containership with 250 days at sea and a HFO price of 400 USD/t. In this case, a 5% reduction in resistance will save approximately 590,000 USD and reduce CO2 emissions by 4,800 t per year.

Compared to trim assistance tools based on logged operational data, decision support systems which purely rely on pre-computed CFD-databases do not require interfacing with the onboard systems, or sensors to monitor operational parameters. These newly developed tools rely solely on the database input of pre-computed values and the operational parameters entered by the crew.

This gives such systems the advantage that they can be installed on any computer on the vessel. No additional hardware and measurement equipment is required, which makes non-interfacing tools very cost effective.

Vessel specific hydrodynamic data is required for the full range of operational conditions specified by the parameters speed, displacement (mean draft) and water depth. This results in a four-dimensional trim matrix.

About 3,500 data points are required to fill the trim matrix. It is therefore not economical to obtain the full trim matrix of the ship specific performance data through towing tank tests, as this would mean 3,500 trials.

Instead, CFD is utilised where the 3,500 calculations take about 2 weeks in the office. The complexity of the problems that are analysed using CFD are in many cases greater than in the aerospace industry. Only the use of parallel computing makes such intensive calculations possible today.

The further use of on-board tools using pre-calculated results, promises greater optimisation in ship operations, further improving fuel efficiency, reducing emissions and enhancing safety.

– by Dr. Torsten Büssow, Vice President, Head of GL Maritime Software

Join The Club

Join The Club