Emma Maersk’s Wärtsilä-Sulzer Super Ship Engine – Part 2

A look "under the hood" of the World's Largest container ship ever built. The engine that powers the Emma Maersk.

It’s been an interesting and tumultuous year in the maritime and offshore sector with both regulatory and commercial drivers contributing to really interesting innovations in the sector.

Here are a few that caught our attention, in no particular order:

1) Hullvane

The naval architects at Van Oossanen in the Netherlands are marketing a foil appendage that is installed on the transom of a vessel which utilizes the upward flow of water coming off the bottom of the hull to capture otherwise unused thrust potential. On certain vessels the company has observed efficiency gains of up to 20 percent while the stern essentially surfs on its own stern wave. Read more about it here.

2. Highly ductile steel plate

Japanese engineers at Steel & Sumitomo Metal Corporation, Imabari Shipbuilding Co, and Japan’s National Maritime Research Institute have introduced new steel technology on board a newly launched 206,600 deadweight ton bulk carrier at Imabari Shipbuilding.

About 3,000 tons of steel plate, called NSafe®-Hull, was installed on this vessel with the ability to withstand greater plastic deformation and achieve higher ultimate strength before fracture. Read more here.

3. SBM Offshore’s Very High Pressure Swivel

Producing oil and gas from ultra-deepwater reservoirs requires equipment that can handle extremely high pressures, not only that, but for facilities like weather-vaning FPSOs, this pressure must be maintained within a system that pivots about a fixed point in the ocean.

Not an easy task.

The engineers at SBM Offshore came up with a swivel that will enable internal operating pressures of 12,000 PSI (830 bar) to be maintained within the the turret on the FPSO. This technology is needed to help provide the water or gas injection pressures needed to keep hydrocarbon-rich formations such as the Lower Tertiary producing. Read more here.

4. Hydrogen / Carbon Dioxide Floating Production Storage and Offloading Concept

During the process of producing hydrocarbons from an offshore well, hydrogen gas and carbon dioxide are also produced in significant quantities as a byproduct. Japanese firms Chiyoda and Mitsubishi Heavy Industries, with support from ClassNK’s Joint R&D for Industry Program, have come up with a new vessel concept that utilizes steam reforming and shift conversion to extract these gases and store them until they can either be transported off the vessel or re-injected back into the reservoir to help maximize the production of the field. Read more here.

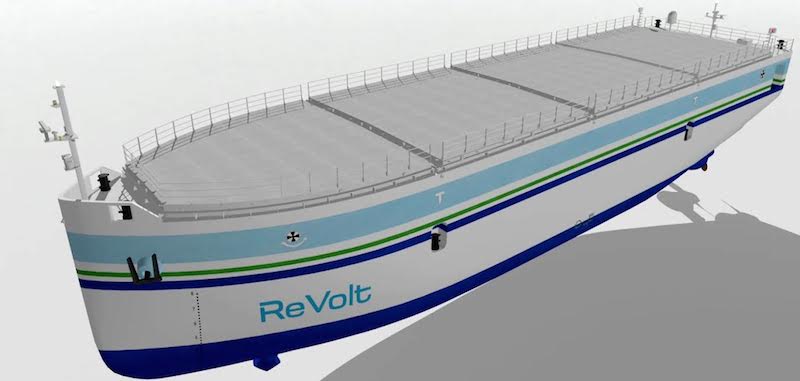

5. DNV GL’s ReVolt Concept

In September, DNV GL released details of a new concept ship design for the short sea shipping market which is battery powered, highly efficient, and, you guessed it, unmanned.

Instead of using diesel fuel or even LNG, ReVolt is fully powered by a 3000 kWh battery, thus reducing operating costs by minimizing the number of high maintenance parts such as rotational components. DNV GL says that, at least in concept, the vessel has a range of 100 nautical miles before a recharge is needed and if the energy required is harnessed from renewable sources, this would eliminate carbon dioxide emissions.

Read more about it here.

6. U.S. Navy Laser Weapon System (LaWS)

The U.S. Navy deployed its first laser weapon system aboard USS Ponce this year, and it was everything we hoped it would be.

The at-sea tests were described as “historic” because not only did they show a laser weapon working aboard a deployed U.S. Navy ship, but also because the LaWS actually worked seamlessly with existing weapon systems.

The prototype focuses the light from six solid-state commercial welding lasers on a single spot, according to a July 31 Congressional Research Service report. It “can effectively counter surface and airborne threats, to include small boats” and drones, said 5th Fleet commander Vice Admiral John Miller. Not only that, but firing it costs about a dollar a shot, according to the Navy.

Watch the video here.

7. MOL Comfort Disaster Explained

The top story on gCaptain in November was a technical article on what likely caused the spectacular loss of the containership MOL Comfort last year. Dr. Ingrid Marie Vincent Andersen from the Danish Technical Institute, was studying the hydro-elastic structural response of containerships similar to the MOL Comfort and had discovered some very interesting details. Surprisingly, her studies had begun well before the loss of the MOL Comfort and were the subject of her PhD thesis.

Read about what her studies showed here.

8. Ulstein’s X-Stern Concept

From the makers of the unmistakable X-Bow hull design reminiscent of a modern-day viking ship, the Norwegian shipbuilding group Ulstein unveiled its X-STERN™ concept this year for vessels that need to maintain station while operating stern-to in a harsh seaway.

The main characteristic of the X-Stern is a sloping and higher stern, which allows for a sharp stern shape where the transom plate is replaced by a pointed stern. According to Ulstein, this results in increased station keeping, reduced wave response, improved crew safety and comfort, and reduced power consumption. Read more about it here.

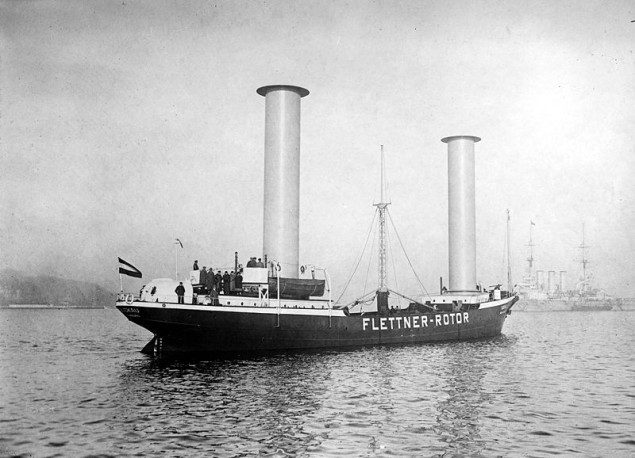

9. Flettner Rotors on an Oil Tanker

In February 1925, the Buckau, a schooner outfitted with cylindrically-shaped, rotating masts 15 meters tall and 3 meters in diameter, crossed the North Sea from Danzig to Scotland to prove the concept of using the Magnus Effect to propel a vessel at sea.

The system was designed by German engineer Anton Flettner and the concept was proven valid.

Over the years however, diesel propulsion took hold and Flettner’s concept never took hold on the global merchant shipping scene. Fast forward 90 years and the idea is now being reborn aboard an LR2 product tanker or Suezmax oil tanker. Read about it here.

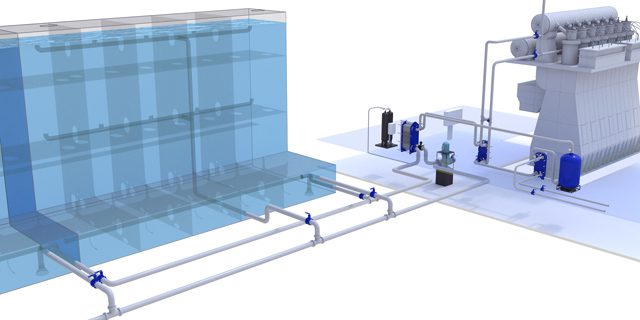

10. Pasteurizing Ballast Water

“Nobody thought it was possible,” commented Kim Diederichsen, CEO of BAWAT AS, a Danish company that created the first type-approved ballast water treatment system utilizing the pasteurization process.

In simple terms, his system cooks and then deoxygenates the ship’s ballast water to kill all the critters that enter the ballast tanks while in port. The vast majority of other ballast water treatment systems, of which there are many, utilize in-line mechanical filtering and UV radiation to eliminate these organisms. Read more about it here.

11. Battery Power

An incredible amount of effort is being put into creating fuel-efficient vessels these days and battery power is coming on strong as means to store energy and provide peak power when needed instead of ramping up and ramping down main engines. For dynamically-positioned vessels, the idea is a no brainer and is gaining traction.

One of the main sources of this technology is Canada’s Corvus Energy which supplies a modular and scalable power system for offshore vessels such as the the Edda Ferd and short sea ferries for Denmark’s Scandlines. Read more here.

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up