Superior tension fatigue, creep life, abrasion resistance and temperature performance – read why Dyneema® SK78 is the fiber of choice for mooring lines

The maritime sector is changing. New mooring guidelines, high safety standards, mounting cost pressures, and increasingly large vessels are just some of the challenges facing operators today.

At the same time, the sector is growing fast, adding pressure to ensure mooring operations are as quick, smooth, and safe as possible.

Mooring ropes made with Dyneema® SK78 provide the reliability to deliver cost-effective, safe and efficient mooring in ever more challenging conditions.

What to look for in mooring lines

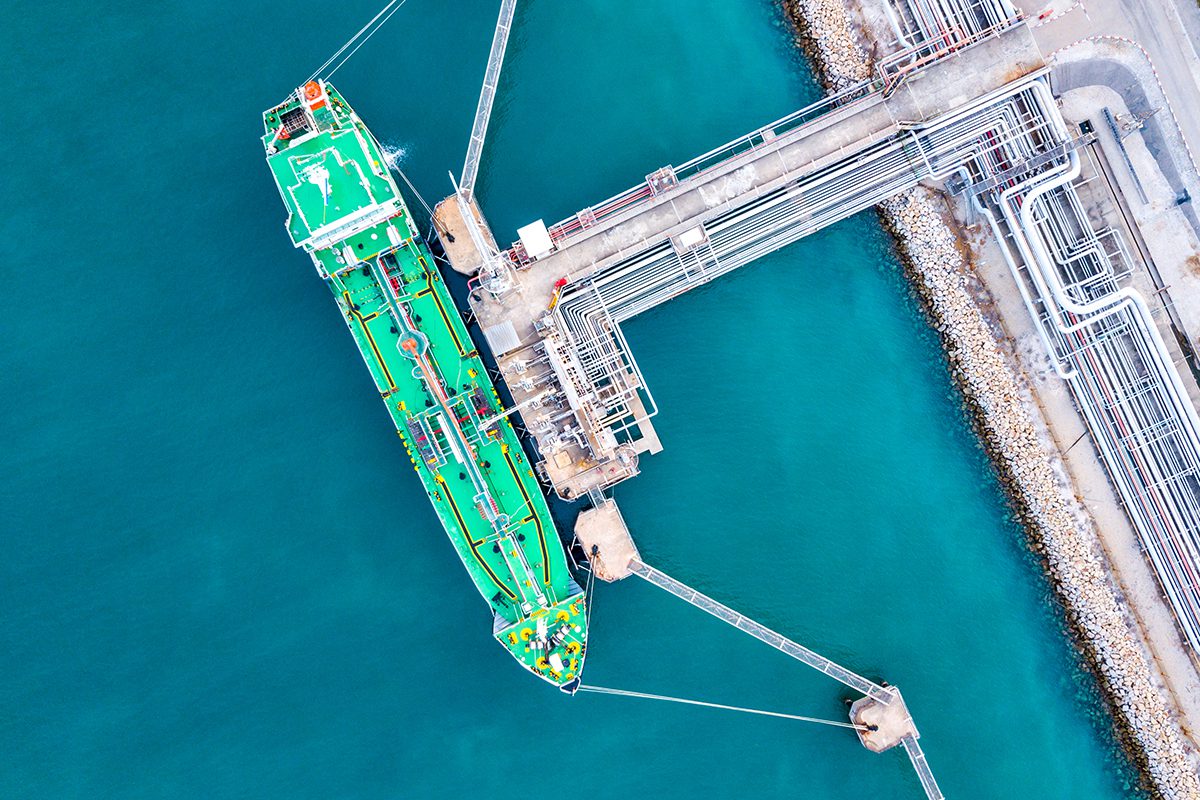

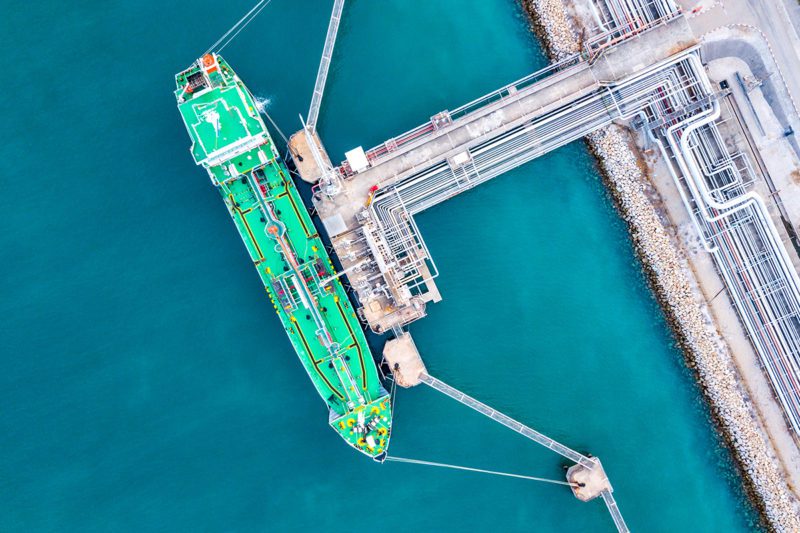

Mooring is a complex operation. Whether securing a huge liquified natural gas (LNG) carrier in the heat of the Middle East, or mooring a freight vessel in frigid Arctic conditions, there are a number of key factors operators need to consider when selecting fiber for mooring lines.

Tension fatigue: Even when moored, wind, waves, and currents keep a ship in constant motion. This movement places stress on the lines, but also means that the tension being placed on them changes all the time – contributing to material fatigue and reducing service life. Dyneema® SK78 is designed to stand up to these pressures by offering at least 3x the fatigue performance of generic HMPE fibers.

Creep life: All HMPE fibers are sensitive to long-term loads, meaning that mooring lines made with the material will elongate proportionally with time. This is known as creep, which can ultimately reduce strength and the lifetime of a line. Dyneema® SK78 offers up to 4x the creep performance of generic HMPE fibers, while accurate performance modelling can further extend the safe service life.

Abrasion resistance: Whether being run through a fairlead or over a capstan, mooring lines are subject to severe abrasive forces that can reduce service life. Ropes made with Dyneema® SK78 have a proven abrasion lifetime that is 4x longer than that of generic HMPE lines, which can be further enhanced by applying a proprietary coating.

High and low temperature performance: Ships are moored in every part of the world, meaning that temperature performance should play a central role in line selection. Dyneema® SK78 performs well at -40C, and even with short-term exposure up to 100°C the ropes keep their performance. The rope temperature models developed by DSM allow for accurate prediction of rope core temperatures in static and dynamic conditions. Thanks to the properties of SK78 and this temperature model, lines made with Dyneema® SK78 can be used at higher operating temperatures than generic HMPE.

Low environmental footprint: Of all high-performance fibers, Dyneema® delivers the lowest carbon footprint per unit strength. Not only is 75% of Dyneema® fiber production based on renewable electricity, longer service life means less material use over the lifetime of a vessel.

Dyneema® SK78 performs exceptionally, but why is this superior performance required in the first place?

Two different fibers, a gulf in performance

Failure to select the right fiber or construction can severely compromise the performance of mooring lines. For BW Fleet Management, this realization came too late to stop seven HMPE mooring lines failing on a single vessel during a mooring operation in Spain. These persistent failures led to a switch to Samson AmSteel®-Blue lines made with Dyneema® SK78. In their first two years of use, the new lines didn’t suffer a single failure.

Based on the experience of other users like COSCO, BW Fleet Management can look forward to many more years of exceptional performance. Since installing mooring lines made with Dyneema® on the COSPEARL LAKE in 2008, the COSCO owned ship has logged more than 11,200 mooring hours. In all this time and in every port, the COSPEARL LAKE has moored using the same original 22 mooring lines made with Dyneema® fiber.

Discover more about Dyneema® SK78

It’s clear that selecting the right mooring ropes is essential to mooring performance. Our premium fiber rope partners are dedicated to making durable, strong and safe mooring and towing ropes with Dyneema® SK78 in accordance with MEG4 guidelines.

Find your nearest mooring and tow rope supplier here, or alternatively, get in touch with our maritime industry experts.

For more detail on the exceptional performance of Dyneema® SK78, read our technical guide.

Tags:

Join The Club

Join The Club