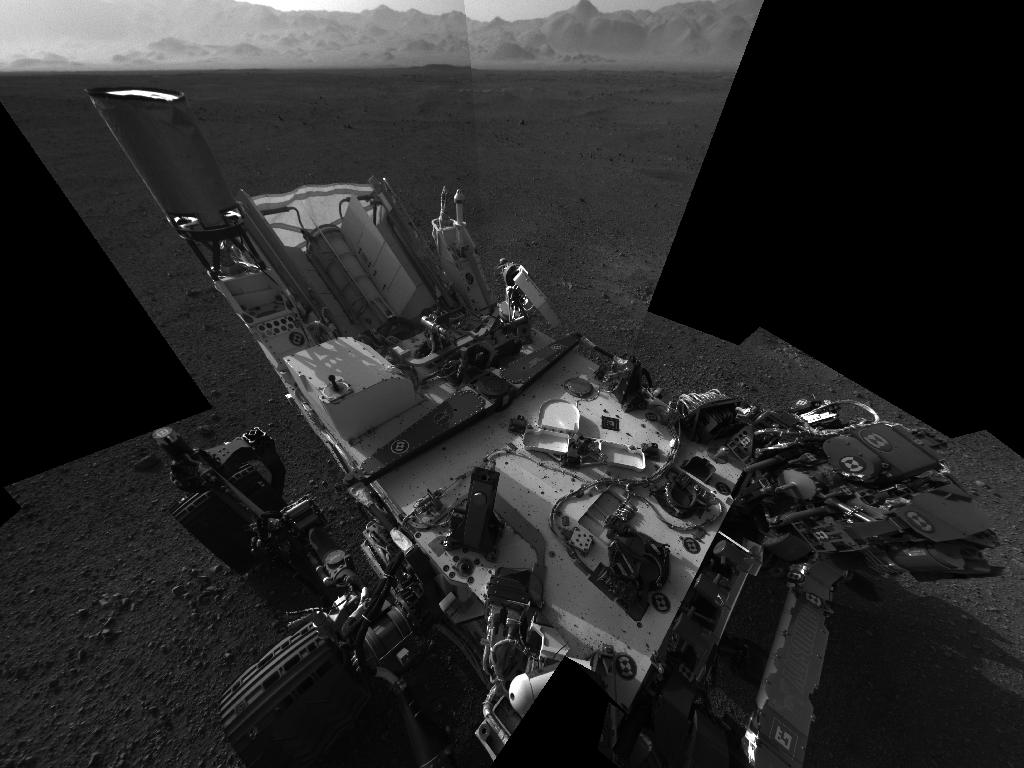

This full-resolution self-portrait shows the deck of NASA’s Curiosity rover from the rover’s Navigation camera. Image credit: NASA/JPL-Caltech

It has been said that the technology used to drill ultra-deepwater oil and gas wells rivals that of NASA. Sometimes those comparisons are more literal than you might expect. Here’s the story of how the offshore oil and gas industry is looking at NASA’s Mars Curiosity rover for tips to help with the exploration of the world’s deepest wells.

(Bloomberg) — NASA’s Mars rover has something to teach the oil industry.

Traversing the Red Planet while beaming data through space has a lot in common with exploring the deepest recesses of earth in search of crude oil and natural gas. Robotic Drilling Systems AS, a Norwegian company developing a drilling rig that can think for itself, signed an information-sharing agreement with NASA to discover what it might learn from the rover Curiosity.

The company’s work is part of a larger futuristic vision for the energy industry. Engineers foresee a day when fully automated rigs roll onto a job site using satellite coordinates, erect 14-story-tall steel reinforcements on their own, drill a well, then pack up and move to the next site.

“You’re seeing a new track in the industry emerging,” says Eric van Oort, a former Royal Dutch Shell Plc executive who’s leading a new graduate-level engineering program focused on automated drilling at the University of Texas at Austin. “This is going to blossom.”

Apache Corp. and National Oilwell Varco Inc., both Houston- based, along with Norway’s Statoil ASA are among the companies working on technology to take humans out of the most repetitive, dangerous, and time-consuming parts of oil field work.

“It sounds futuristic,” says Kenneth Sondervik, sales and marketing vice president for Robotic Drilling Systems. He compares it to other areas that have become highly automated, such as car manufacturing or cruise missile systems.

Tough Sell

Until recently, robots have been a hard sell in an industry that has long relied on human ingenuity, says Mark Reese, president of rig solutions at National Oilwell Varco.

“In the past, it’s been all about, ‘We need more and more people and experience, and that’s the only way to accomplish this task,’” Reese said.

The 2010 BP disaster in the Gulf of Mexico helped shift attitudes, says Clay Williams, chief financial officer at National Oilwell Varco. Eleven men were killed when the Deepwater Horizon rig caught fire and sank. Statoil has projected that automation may cut in half the number of workers needed on an offshore rig and help complete jobs 25 percent faster, says Steinar Strom, former head of a research and development unit on automation at the Norwegian company.

Robot Deckhands

Robotic Drilling Systems is designing a series of robots to take over the repeatable tasks now done on rigs by pipehandlers, deckhands and roughnecks. Its blue, 10-foot-tall robot deckhand has a jointed arm that can extend about 10 feet, with 15 or so interchangeable hands of assorted sizes. The robot is anchored in place to give it better leverage as it lifts drill bits that weigh more than a ton and maneuvers them into place.

The Sandnes, Norway-based company also is collaborating with researchers at Stanford University on a three-fingered robot hand embedded with sensors that give it a touch delicate enough to pick up an egg without crushing it.

The Mars rover is designed to collect data and take action on its own based on programmed reasoning. As a step in that direction, some companies are working on technology that will make drill bits more intelligent and able to respond instantly to conditions they encounter, such as extreme temperatures or high pressures.

National Oilwell Varco, the largest U.S. maker of oilfield equipment, and Schlumberger Ltd., the world’s largest oilfield services provider, have developed drill pipe wired with high- speed data lines to allow the bit to feed information to workers at the surface.

Thinking Bits

Apache, the third-largest U.S. independent oil and natural- gas producer by market value, is writing software that will essentially allow the drill bit to think for itself, communicating directly with equipment at the surface that controls speed and direction.

Graham Brander, the company’s director of worldwide drilling, sees it working much like a plane on autopilot, flying on its own with a human on standby, ready to assume the controls if necessary.

“That’s what I view very much as the automation model for the oil and gas business,” he says.

Other breakthroughs are taking place onshore, where producers are racing to drill tens of thousands of wells in U.S. shale fields. On a recent morning in north Houston, Johnny Alverson, a senior foreman at rig builder Drilling Structures International Inc., fired up an 1,800-horsepower John Deere engine and picked up a remote control box as big as a car battery as he prepared to move a 167-foot-tall drilling rig without the aid of a crane.

With the push of a couple of buttons on the remote, the green light lit up next to “walk” and the rig slowly heaved itself up five inches off the ground on four large, flat feet. The $20 million monster can move at a rate of a foot a minute. Says Drilling Structures Executive Vice President P.J. Rivera: “You start to feel good about yourself when you can pick up a million pounds with the flick of a thumb.”

-By David Wethe. Copyright 2012 Bloomberg.

Editorial Standards · Corrections · About gCaptain

Join The Club

Join The Club