World’s Longest Subsea Power Cable Sparks Up

By Rachel Morison (Bloomberg) –The first megawatts of electricity will flow between Norway and the U.K. Wednesday along the longest submarine power cable in the world. Once fully operational Britain...

Updated: September 12, 2016 (Originally published June 25, 2013)

An interesting trend in recent years has been the increase in high spec supply vessels ordered to service the offshore oil and gas industry, in addition to larger vessels needed to support ultra-deepwater subsea pipelay and construction projects.

Imagine a crane 10,000 feet up in the sky, hanging a wire down to the ground and picking up a fully-loaded mining truck like the Caterpillar 797F pictured below.

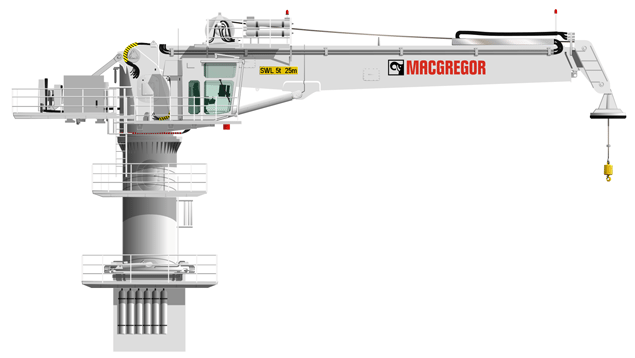

That’s pretty much what we’re talking about here, except that the cranes such as this MacGregor offshore crane is attached to a ship floating in the ocean

MacGregor has even unveiled a design for a 900-ton active heave compensated crane, pictured below:

The only pieces of gear that I can think of which would challenge the capacity of such an enormous crane would be if a deepwater blowout preventer got dropped, but to be sure, a crane of this size would create its own market, which it already has. In May, Sealion Shipping placed a 22 million euro order for this crane which is to be installed on their new multi-purpose offshore construction vessel currently being built at Hyundai Heavy Industries. MacGregor notes that the driving factor for larger cranes such as this has been the widespread use of larger and heavier subsea modules being used in the design of deepwater subsea oilfields, in addition to the additional weight of the lifting cable being used.

“This is the first subsea crane of this capacity and design that has ever been been ordered,” says Frode Grøvan, Director, Sales and Marketing for Advanced Load Handling. “At a time when subsea modules are getting larger and heavier and operations are being conducted at ever greater depths, a sophisticated crane on this scale equips the new vessel to meet the ever increasing demands of the offshore construction market.”

I spoke with Mr. Grøvan at the NorShipping conference in Oslo the other week and he pointed out an important factor in the usage of high-spec, ultra deepwater cranes… the weight of the cable becomes a highly limiting factor that reduces the capacity of the crane during deepwater lifts.

To compensate for that issue, crane manufacturers like MacGregor are turning to a high strength material called Dyneema. Used in the mooring lines for ultra-deepwater oil and gas production units like Shell’s Perdido Spar, on board tugboats, and in the sails and rigging of offshore racing sailboats, replacing thousands of feet of heavy wire rope with Dyneema is a solution to the weight issue.

The Dyneema rope isn’t spooled on to the crane however, it’s used more like a really long leader on fishing tackle and only a short amount of the wire rope is lowered into the water.

Besides going ever larger, offshore cranes are being designed to do things that are increasingly more complicated, with narrower margins for error. Nowhere else is this more apparent than in the offshore wind sector.

Siem Offshore approached MacGregor with requirements for a one-of-a-kind crane with the ability to land containers of tools and equipment on small, high platforms such as the top of offshore windmill foundations, with little margin for error.

Designed especially for the 74 meter Siem Moxie, an infield supply vessel (ISV) under construction at Fjellstrand shipyard in Norway, this new crane has some amazing features that enables it to accomplish its mission in significant wave heights of up to 3 meters.

While operating from the DP3-controlled Siem Moxie, the crane will have active-heave compensation (AHC) to keep loads vertically on target, but for a rolling ship in a 3 meter seaway, AHC wasn’t going to cut it. To solve the problem, MacGregor engineered a hydraulically actuated two-directional motion compensation system employing four high-speed hydraulic cylinders at the base of the crane. With the AHC and the two-axis motion compensation system tied into the ship’s motion reference unit (a gyro), the system allows full three-axis (x, y and z) compensation which keeps a suspended load fixed in a selected position within the crane’s operational parameters.

With the three-axis compensation activated, the jib’s luffing and slewing controls remain fully functional. “This makes precise load positioning possible without shutting down the compensation mode or moving the vessel,” Mr. Grøvan says.

“While a similar operational end result might have been achieved by making use of the crane’s luffing and slewing functions to control the position of the head of the jib, it would have resulted in a more complex solution and it would have been difficult to achieve the required speed of response.”

MacGregor notes that the crane can also be used for a variety of other purposes, including ship-to-ship operations.

Under normal circumstances, the constant tension function is used to compensate for the motion of a second vessel when lifting a load from its deck. “When the hook has been connected to the load with a slack wire, the crane operator activates constant tension. The wire is pulled in by the winch and kept at a pre-tensioned level until the operator is ready to lift the load off the second ship by deactivating constant tension and pulling the wire in at full tension,” notes Grøvan.

The crane has a safe working load of 5 tons at a 25m outreach and features a telescopic jib, operated by a hydraulic rack-and-pinion system, to achieve the required combination of lifting height and compactness when not in use.

Delivery of the crane is scheduled for January 2014.

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up