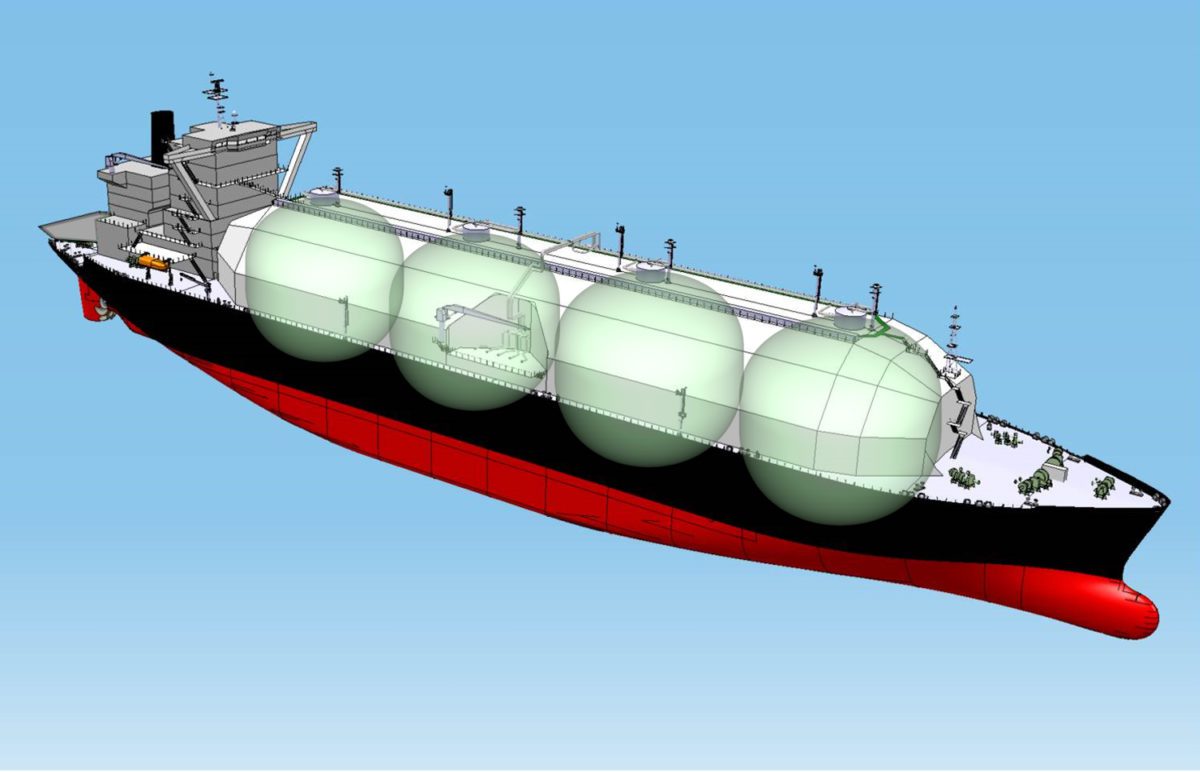

An illustration of a “Sayaringo STaGE” LNG carrier design. Image: MHI

Tokyo-based Mitsubishi Heavy Industries said Wednesday it has secured two orders from Japanese clients to build next-generation LNG carriers to transport U.S. gas.

MHI says that one LNG carrier each will be delivered to two joint ventures that Chubu Electric Power Co. has established with Mitsui O.S.K. Lines (MOL) and Nippon Yusen Kabushiki Kaisha (NYK Line), respectively.

The vessels will be built to the so-called “Sayaringo STaGE” design, which achieves significant improvements in both LNG carrying capacity and fuel efficiency through the adoption of a more efficient hull structure and an innovative hybrid propulsion system.

Both vessels on order are scheduled for completion and delivery in 2018, at which point they will be put into service for transporting North American-produced shale gas primarily from the Freeport LNG Project in Texas, an initiative in which Chubu Electric Power is participating.

The two orders were received through MI LNG Company, Limited, a joint venture between MHI and Imabari Shipbuilding. The vessels will be constructed at MHI’s Nagasaki Shipyard & Machinery Works.

The vessels will have a length overall of 297.5 meters, width of 48.94m, depth of 27.0m and draft of 11.5m. Each carrier comes with four apple-shaped tanks, an improved version of Moss-type tanks designed with a bulging upper half. Total holding capacity of the tanks will be 180,000 cubic meters (m3).

The adoption of a tank cover integrated with the hull, developed by MHI with support from Aker Arctic Technology, enables a lighter vessel while fully retaining overall structural strength. The new design also reduces wind resistance during navigation.

MHI notes that the vessels will have a width allowing for passage through the expanded Panama Canal.

The LNG carriers on order will also feature a hybrid propulsion system dubbed “STaGE” (Steam Turbine and Gas Engines). MHI say that plant efficiency has been substantially improved through the effective use of the engine’s waste heat for steam turbine, resulting in a highly-efficient propulsion system at a range of speeds.

The latest two orders come on the heels of an order for two Sayaringo STaGE LNG carriers in April, preceded by an order placed in January for two next-generation LNG carriers to transport shale gas produced in North America.

Effective October 1st MHI will launch a wholly-owned ship construction company and transfer all operations in the construction of large-scale commercial ships in the Nagasaki district to the new entity. MHI says that the initiative will focus the company’s shipbuilding structure on the construction of gas carriers, a vessel type that MHI is considered a leading shipbuilder of.

The Freeport LNG Project is underway at the Freeport LNG terminal in Texas and calls for the establishment of a new natural gas liquefaction facility to refine and liquefy shale gas and other natural gases produced in the U.S. at a rate of up to 13.2 million tons per year. The launch of commercial production is scheduled for around 2018.

Join The Club

Join The Club