Part 4 in our series continues on with a look at Dynamic Positioning and how it is used on more conventional, deep sea vessels.

Make sure to look at Part 1, Part 2 & Part 3 as well!

Shuttle Tankers

Used for running product between FPSO’s & the beach, shuttle tankers now conduct the loading on DP, as opposed to the more traditional mooring techniques.

In the past shuttle tankers were conventional single hulled vessels modified for offshore loading. These days they are purpose built DP Class 2 vessels. Generally they will be twin screw with independent rudders, two bow & two stern thrusters, one of which will likely be a retractalbe azimuth type.

3 reference systems will be used for class 2 operations. DGPS in north america is the standard, while in the North Sea DARPS in more commonly used. (FACT CHECK)Artemis & acoustics will make up the other two.

DP operation of these ships is based on the weather vane principle, meaning that the tanker will try to maintain position that keeps the environmental forces at a minimuum, thereby reducing power output.

The artemis can be kept on the FPSO & used as a relative reference so that the shuttle tanker will stay a set distance off, even though both vessels are influenced by the sea state. This helps to prolong the life of the product hose & reduces the risk of the vessels making contact.

Advantages to using shuttle tankers as opposed to pipelines:

- No need for connections of pipelines

- Storage right on the vessel, which can also be DP operated

- No mooring costs

- Easy & quick hookup, connection & disconnection

- Safe distance can be maintained from FPSO

- Weight & cost savings as certain equipment can be relocated or removed from vessel

- Due to weather vaning, the system can operate in extreme conditions

Traditionally a shuttle tanker would be moored either to a buoy or directly to the FPSO. Mooring in DP takes an extra step out of the equation, making the operation intrinsically safer.

Cruise Ships

The cruise industry continues to embrace DP technology.

Due to the high profile nature of the industry, cruise liners have traditionally been on the leading edge of environmental protection policies. There will be an officer onboard strictly in charge of this policy & will ensure that there is Zero Discharge from the vessel.

Cruise liners often trade in tropical locations with fragile marine ecosystems. By utilizing DP instead of anchoring off an island it saves damage & disruption to the subsea environment.

Additionally, with the size of the vessels ever increasing, using DP to aid in docking operations increases the safety of the job & can reduce the time taken to complete the operation.

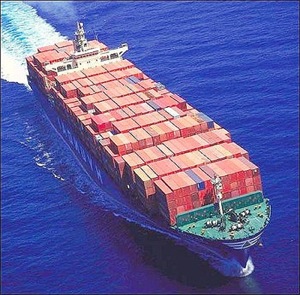

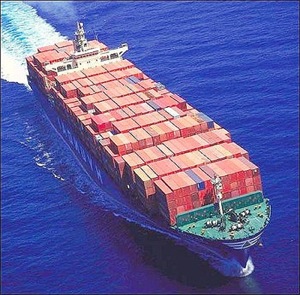

Cargo Vessels

The case for DP onboard cargo ships is much the same for that of the cruise ships.

Reducing anchor usage results in less damage to the marine environment & can allow for a less stressful wait at the pilot anchorage. Cargo ships may need to turn or manouvre in tight quarters to access an assigned dock.

Running DP also reduces the need for tugs which can make the operation run smoother & cost less.

Join The Club

Join The Club