Offshore Giants: The World’s Deepest Wells & Biggest Platforms

When the first offshore well was drilled off the coast of Summerland, California, in 1896, few could have imagined just how far the industry would go. That wooden pier-mounted rig...

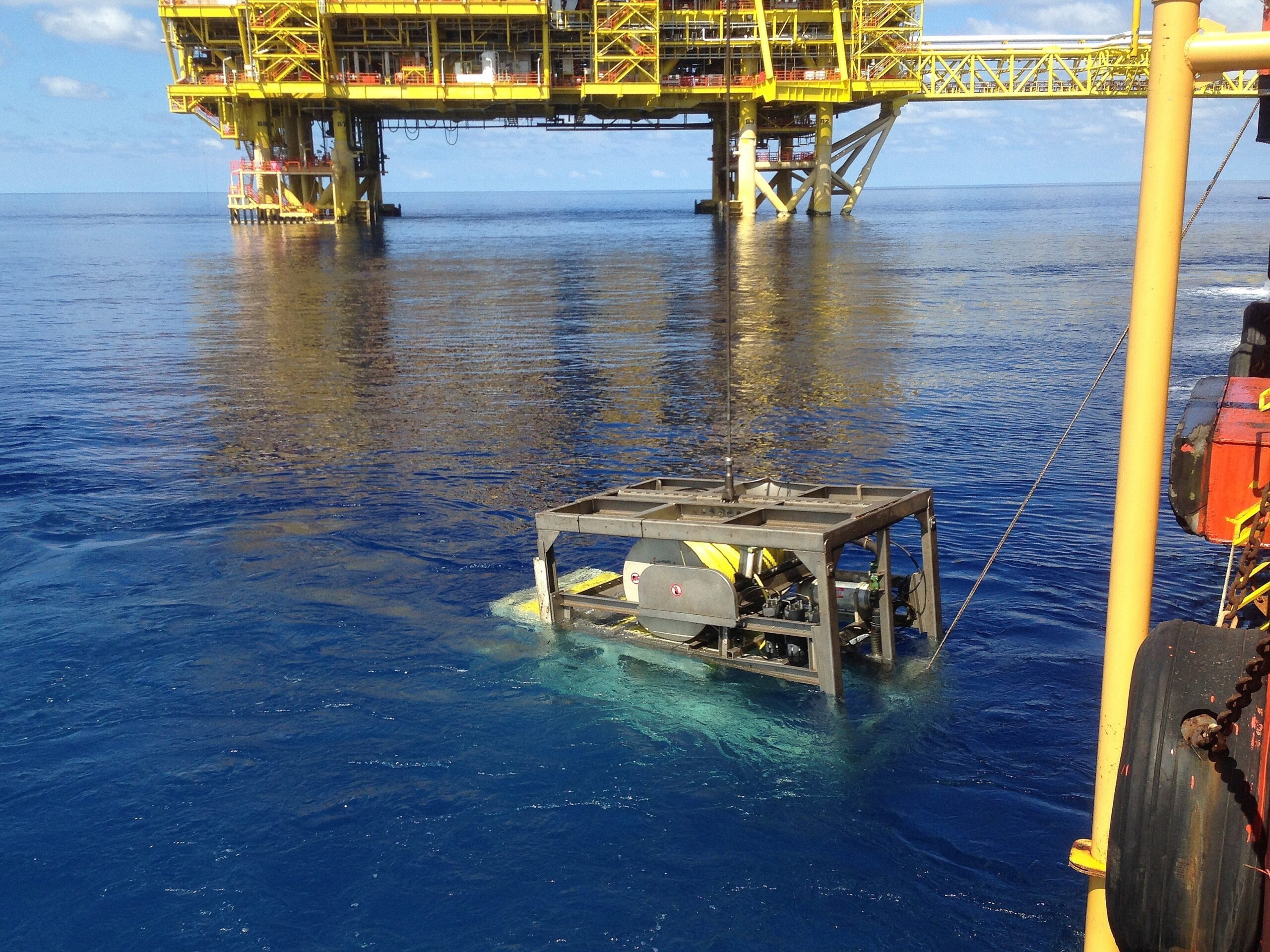

The oil and gas industry has always relied on innovation to explore further, drill deeper, and increase production. Today, one of the most transformative tools in offshore oil and gas operations is the remotely operated vehicle, or ROV—a highly specialized robot designed to work in some of the harshest underwater environments on the planet.

ROVs are helping companies inspect, repair, and maintain vital underwater infrastructure without putting divers in harm’s way. But like every piece of offshore technology, they come with their own set of risks and raise new questions about the future of offshore work.

A remotely operated vehicle is an unmanned, tethered robotic system controlled from the surface, typically from a support vessel or drilling rig. The tether usually provides power, communication, and control signals to the ROV, although some deepwater ROVs may be battery powered, with the tether primarily used to transmit images or other information. When used in offshore oil and gas operations, ROVs are equipped with cameras, sensors, robotic arms, and specialized tools for various underwater tasks.

ROVs are controlled by pilots or technicians stationed on the surface. They can operate thousands of feet below the surface, withstand extreme pressure and temperatures, and work for long periods—making them invaluable in deepwater oil and gas operations where divers cannot safely reach.

ROVs have proven essential in some of the highest-stakes offshore operations in history. They played a critical role in monitoring and capping the well during the Deepwater Horizon disaster, performing tasks no human diver could have safely attempted at such depths. ROVs were also instrumental in surveying and assessing damage after Hurricane Ida and other Gulf of Mexico storms, helping operators inspect risers and subsea infrastructure when conditions made diver intervention impossible.

Beyond the oil and gas industry, ROVs have made historic contributions, such as locating the wreckage of the Titanic and the Bismarck (both found by the ROV Argo) and assisting in the recovery of the flight data recorder for Air France Flight 447 in April 2011, after it crashed into the Atlantic Ocean in June 2009.

ROVs perform a wide range of tasks essential to offshore exploration, production, and maintenance. Their most common uses include:

Inspection & Surveying

ROVs provide high-definition video, sonar mapping, and real-time monitoring of pipelines, risers, and subsea wells, allowing operators to detect leaks, cracks, or structural fatigue before they lead to major accidents.

Maintenance & Repair

Equipped with hydraulic arms and precision tools, ROVs can clean marine growth from platforms, tighten bolts, cut damaged pipelines, and even replace components—all without human divers entering the water.

Well Intervention & Drilling Support

ROVs assist with installing subsea equipment, operating valves, and supporting drilling operations by clearing obstructions and monitoring wellheads.

Emergency Response

After accidents like blowouts or equipment failures, ROVs may be deployed to cap wells, inspect damaged structures, and help contain spills.

The development of miniature ROVs has introduced even more possibilities, including automated cleaning of underwater surfaces to prevent corrosion and improve operational efficiency.

Perhaps the greatest benefit of ROVs is their ability to take on some of the most dangerous underwater tasks traditionally handled by divers. By replacing or supporting diver-based operations, ROVs reduce exposure to extreme pressure and cold underwater temperatures, minimize the risk of decompression sickness and other dive-related injuries, and allow work in conditions too deep, remote, or hazardous for human intervention.

In many ways, ROVs act as the “eyes and hands” of offshore crews, allowing operators to inspect and repair subsea systems from the surface.

ROVs are operated by specialized personnel known as ROV pilots or ROV technicians. These professionals typically work in control rooms aboard offshore vessels or platforms, using joysticks and computer interfaces to guide the vehicle. ROV pilots undergo rigorous training to handle the complex equipment and troubleshoot problems in real time.

ROV teams typically include:

While ROVs keep divers out of hazardous deepwater environments, they are not risk-free. Incidents related to the lowering or lifting of ROVs using winches and other equipment are one of the most common hazards, as indicated by recent Bureau of Safety and Environmental Enforcement (BSEE) incident reports, including a June 2021 accident involving an ROV technician whose hand was crushed during launch.

ROV operations can create or contribute to other dangers:

ROV pilots may also be exposed to other risks that come with living and working on a fixed platform or vessel: slip and fall accidents on deck, falls overboard, being struck by swinging or falling objects, exposure to toxic chemicals, and even fires or explosions.

For offshore workers, ROVs are somewhat of a double-edged sword. They have taken on some of the most dangerous underwater tasks, but they also introduce new risks and require crews to work around complex, high-voltage machinery. Launch and recovery operations, heavy equipment, and long shifts in stressful environments bring their own hazards, meaning ROVs are not a simple fix for offshore safety.

Workers must be trained not only to operate or interact with ROVs safely but also to recognize the risks these machines bring to decks and launch areas. Employers must ensure safety processes evolve as rapidly as the technology itself.

ROVs have already reshaped offshore operations, and their impact will only continue to grow by:

Looking to the Future: Will ROVs Replace Humans?

Despite their capabilities, ROVs lack human judgment and intuition. Critical decisions—especially during emergencies—still depend on experienced offshore crews. We are most likely to see ongoing collaboration, with ROVs taking on the most hazardous work while humans oversee operations, interpret data, and make key decisions.

In an industry where accidents can have devastating consequences, the safe and responsible use of ROVs will remain just as important as the technology itself. Offshore workers deserve to know that these powerful machines are being used to protect lives and improve safety—not just boost production.

###

Founded in Houston, Texas, by Kurt Arnold and Jason Itkin in 2004, Arnold & Itkin has become the national leader in maritime law. The firm has helped after every major maritime disaster over the past two decades, taking on the biggest companies in the world to find answers and justice for injured seamen, offshore workers, and their families. The firm’s trial attorneys are known for their grit and determination, securing more than $20 billion in verdicts and settlements for clients across the United States.

Sign up for gCaptain’s newsletter and never miss an update

Subscribe to gCaptain Daily and stay informed with the latest global maritime and offshore news

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up