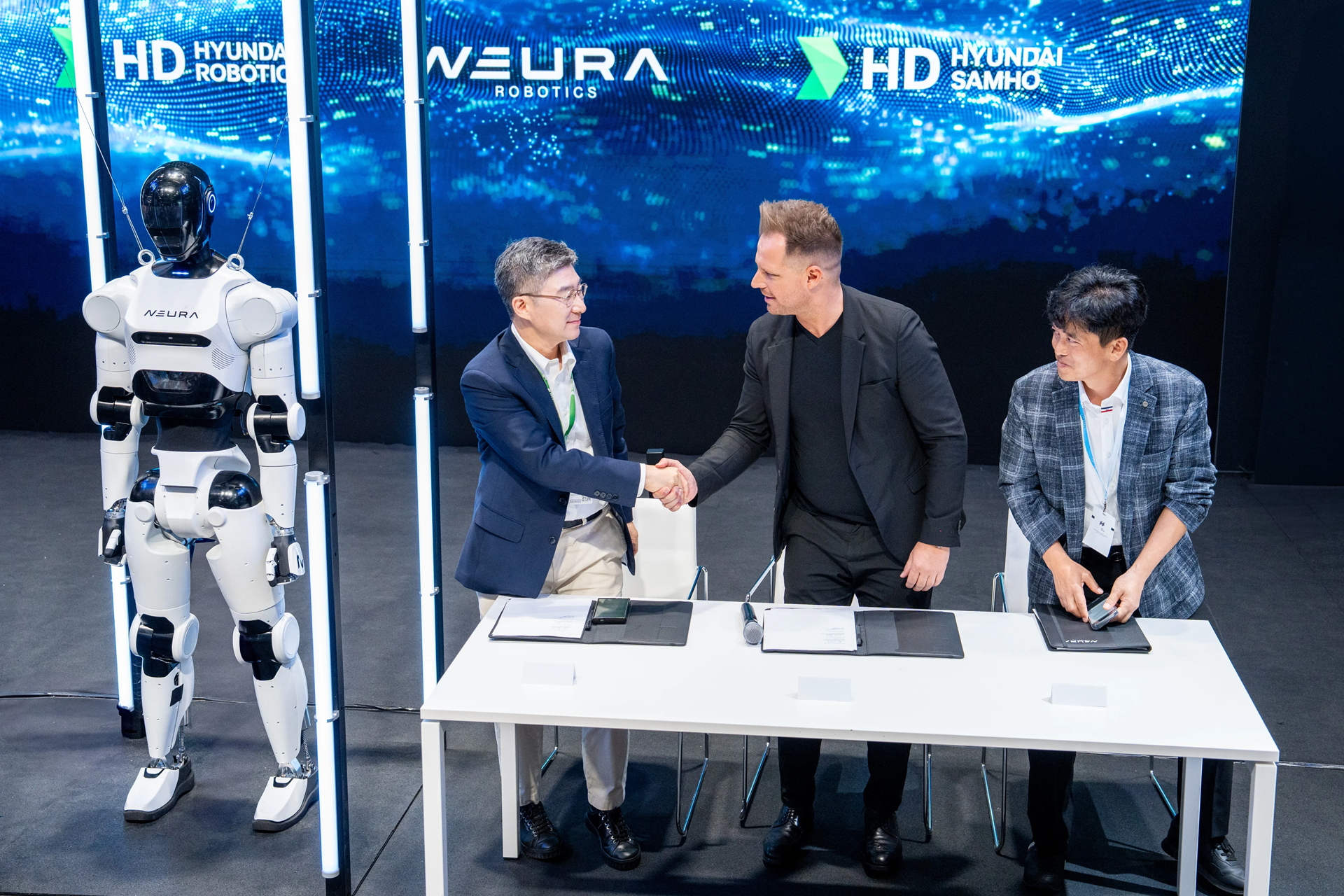

Two units of South Korean shipbuilding conglomerate HD Hyundai have signed a strategic partnership agreement with Germany’s NEURA Robotics to develop specialized humane-like welding robots for the shipbuilding industry.

The agreement, signed in Munich at the end of June, focuses on developing robots capable of navigating the complex environment of shipyards while performing precision welding tasks, aiming to address growing labor shortages while boosting safety and productivity.

Under the terms of the agreement, HD Hyundai Samho will provide testing environments and validate the robots’ practical applicability based on their experience with collaborative robots and automation equipment. HD Hyundai Robotics will contribute technical expertise, including path learning data from years of welding automation experience. NEURA Robotics will leverage its cognitive robotics technology, including its humanoid platform 4NE-1, to develop solutions specifically for shipbuilding applications.

“This agreement will be an important milestone that will demonstrate the infinite possibilities and expandability of cognitive robots in the world’s most demanding environment of the shipbuilding industry,” said David Reger, CEO of NEURA Robotics.

South Korea’s shipbuilding industry has rebounded strongly from the COVID-19 pandemic, but has been grappling with persistent skilled labor shortages.

Sanghun Ryu, Executive Director of HD Hyundai Samho, stated: “We will take a leading role in creating a safer and more productive shipyard environment by applying specialized welding robots that meet the diverse quality requirements of the shipbuilding industry.”

Editorial Standards · Corrections · About gCaptain

Join The Club

Join The Club