Amidst a crazy windstorm this week that briefly grounded a Maersk containership and delayed flights all along the coast of the North Sea, I had the opportunity to visit Royal IHC shipyard and HSM Offshore, two industrial yards located in The Netherlands which are operating on the front lines of the offshore oil and gas industry.

Royal IHC, previously known as IHC Merwede, is a company that specializes in the design and building of offshore construction, dredging vessels and specialized pipelay equipment.

Subsea 7’s 550 ton pipelay vessel Seven Rio was launched last November from the ways at Royal IHC. The vessel has an overall length of 146 meters, beam of 30 meters and is DP-2 equipped. She features a vertical (tiltable) pipelay system with a 550t top tension capacity and twin ROVs which are deployed over the port and starboard sides of the vessel. She is fitted with two under-deck storage carousels, with a capacity for 2,500t and 1,500t of product respectively.

Seven Rio is Lloyd’s Register classed, as the Plimsoll line above shows, and is destined to work for Petrobras at the Libra Project.

For those not familiar, the Plimsoll line is a reference mark on a ship’s hull that indicates the maximum depth to which the vessel may be safely immersed when loaded with cargo. The “F” in this case indicates Fresh Water. A vessel loaded to her fresh water mark will float higher in the water as she moves into salt water due to salt water’s higher density.

Below, the Sapura Jade is one of six new vessels ordered by TL Offshore, subsidiary of SapuraKencana from Royal IHC.

Vessel Particulars:

- Length overall: 155.97m

- Length between perpendiculars: 135.22m

- Breadth: 29.94 m

- Depth: 13 m

- Design draught: 8.3m

- Scantling draught: 8.5m

- Speed: 13.6 kn

- Deadweight 10,800t

- DP Class 2

- Main crane capacity: 250t

- Pipe capacity: 4,000t

- Maximum diameter: 630mm

- Operating depth: 2,500m

- Total installed power: 23,040kW

On the aft deck there is equipment which allows the vessel to load two strings of pipe via the vessel’s two carousels simultaneously, saving a significant amount of time while at the spoolbase.

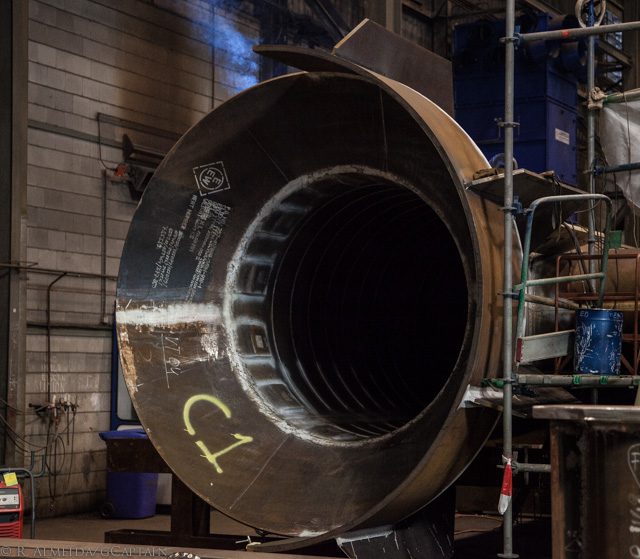

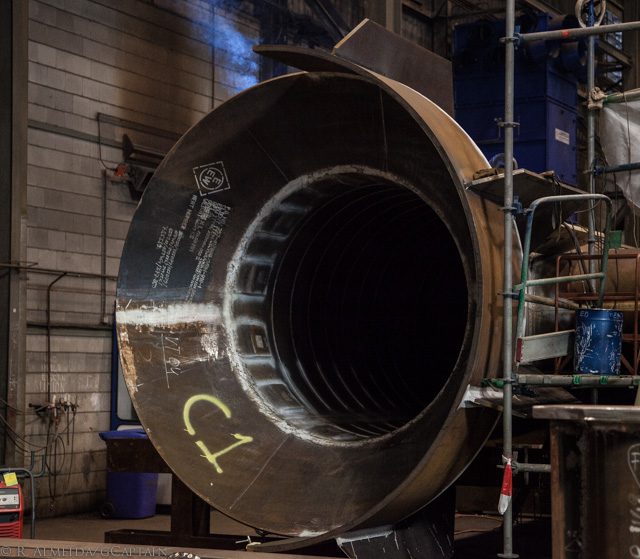

The upside down bow section of a newbuild (above)

The cross section of a newbuild for SapuraKencana.

An air hose is outfitted to the welding mask of a welder at Royal IHC providing fresh air.

For welders, this setup provides a huge safety upgrade while improving their quality of work.

At Royal IHC, there aren’t masses of people running around like ants throughout the yard, much to the surprise of clients such as Petrobras who initially questioned their ability to deliver their ships on time. Nonetheless, via careful planning, their ships have been regularly delivered ahead of schedule.

At Schiedam, and across the inlet from Damen Ship Repair is HSM Offshore, a company that specializes in the building of topsides facilities and jackets for fixed offshore facilities.

Below, Jaco Fleumer, HSM Offshore’s Business Development Manager points to the 1800 ton Flyndre Cawdor process module which is under construction for Aker Solutions in support of Talisman Sinopec Energy UK ‘s Clyde platform in the U.K. North Sea.

The module will receive and process the hydrocarbons from Maersk Oil UK’s Flyndre and Cawdor fields, which are being developed with subsea manifolds and a flowline to the Clyde platform.

In the background stands the 1100 ton topside of the Petrogas E&P Netherlands A18 platform, which will be installed in the Dutch North Sea late summer 2015 to develop a shallow gas field.

A welder’s arc reflects on the walls of the shed where parts of the jacket (substructure) for the Petrogas A18 platform is being built. This platform will be installed in 44 m water depth in the northern sector of the Dutch North Sea.

Join The Club

Join The Club