Choosing The Right Mix Of Forecasts For Offshore Planning

Getting a reliable mid-term picture of the weather can affect a company’s bottom line. See how you can gain forecast confidence beyond the standard period of accuracy. With volatile oil...

Benny Cenac, CEO of Cenac Marine Services and Houma native, takes great pride in continuing his family’s multigenerational business and legacy. One of his family businesses, Houma Machine & Propeller, is a renowned propeller shop, selling and repairing ship propellers of various sizes all over the world.

Ship propellers have advanced greatly over the years. Today, the largest propeller has a diameter of 31.5 feet, and sits on the Emma Maersk, one of the longest ships every constructed at a staggering 1,302 feet. The propeller took one and a half years of development and planning before it was completed. Houma Machine & Propeller services propellers up to 15 feet in diameter.

Conventional propellers were attached to the boat by a long shaft. However, they have evolved and now can be fitted on the boat as a compact unit, attached directly to the back of the boat. Benny Cenac, Houma business owner, still finds the conventional propellers attached by a shaft to work the best for some boats and incorporates both this method and the newer method in his work at Houma Machine & Propeller.

Copper and metals are generally used for ship propeller building, because of their resistance to corrosion and because they have good machinability, meaning the ease with which the metal can be cut. Some commonly used metals are aluminum, stainless steel, nickel, and bronze, though most propellers are comprised of some combination of these. Constructing a propeller involves attaching blades to the hub by welding or forging them into one piece.

Benny Cenac’s Houma Machine & Propeller sells propellers for all kinds of ships, from inland river push boats to large, offshore vessels. The type of vessel determines what kind of propeller it should be fitted with: this includes the number of blades, the shape of the blades, the size and number of propellers, and so on.

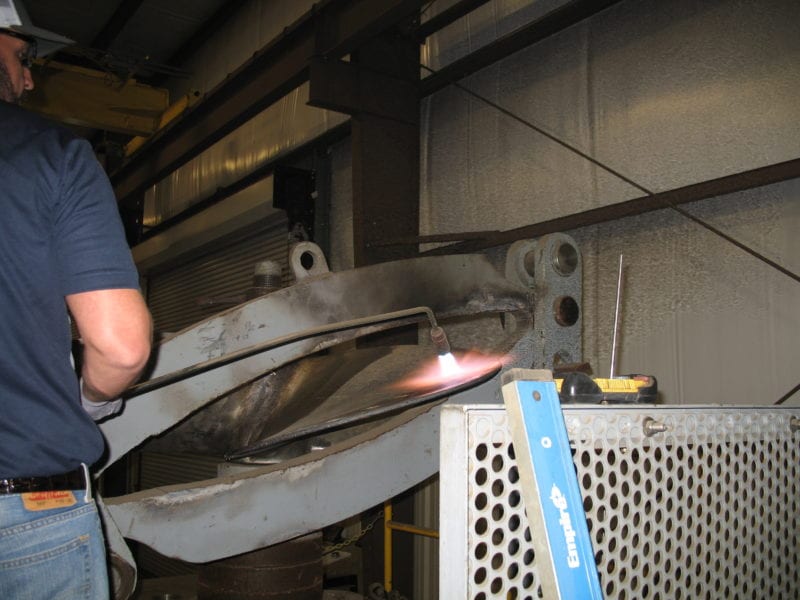

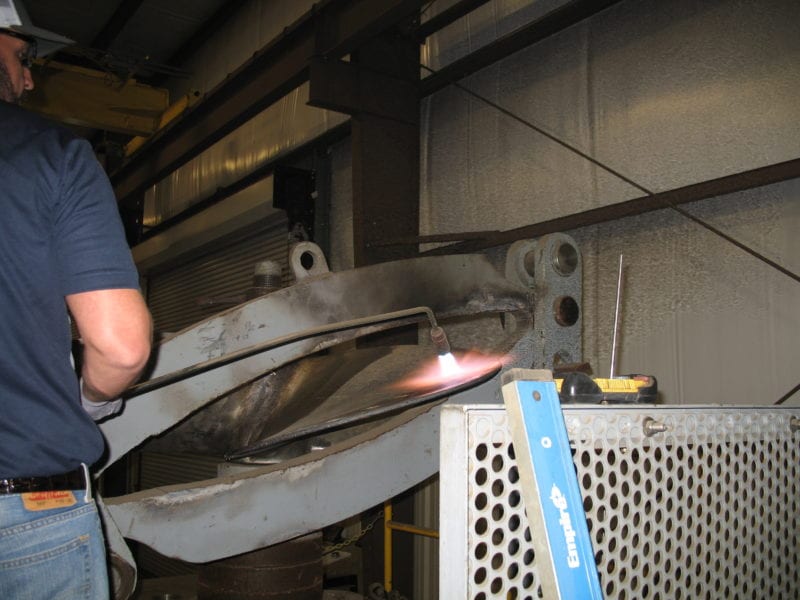

Repairing propellers requires a great deal of expertise. Propeller blades must be in exactly the right shape and perfectly smooth in order to maximize boat speed and efficiency. As a result, the process requires a great deal of hand work, something which Benny Cenac and his team have fully mastered.

Propellers may be brought into Houma Machine & Propeller for repair after corrosion or even from hitting something and breaking. To repair them, propellers are set up on stands, and the blades are heated up until red hot and then beat until flat. Sometimes the blades are even slid into a press if the damage is extensive enough.

The skill and expertise of propeller repair and rehab is acquired through hands-on experience. Benny Cenac’s skilled tradesman take great pride in their hands-on approach to every propeller project. The process is so particular that it cannot be done on a machine. Plus, each propeller is distinctively unique, requiring different care and attention than the next.

Repairing propellers is a long, tedious process. If propellers arenot repaired just perfectly, the whole boat will vibrate so it’s important to the employees at Houma Machine & Propeller that they fix the propellers just right before sending them back out on boats. Houma Machine & Propeller prides itself on repairing propellers so well that, when fitted back onto a ship, the ship runs so smoothly that you could place a nickel on the edge of the ship and it wouldn’t bounce off.

Propellers that have been in use for long periods of time may begin to corrode regardless of how well they were made or taken care of. But Benny Cenac’s prop shop can get these propellers working good as new! His experienced workers can get old propellers shiny and smooth again.

Living among some of the most expansive wetlands in the world and just a few miles away from the coast, working on boats makes Benny Cenac feel like he is contributing positively to his community. Marine and recreational activities play a crucial role in Louisiana’s economy, from fishing to towing and more. Whether he’s helping a local fisherman repair his old propeller or fitting a large commercial vessel with a brand-new propeller, Benny Cenac knows that the work he is doing is positively affecting the lives of local Louisianans.

Join the gCaptain Club for curated content, insider opinions, and vibrant community discussions.

Join the 105,933 members that receive our newsletter.

Have a news tip? Let us know.

Access exclusive insights, engage in vibrant discussions, and gain perspectives from our CEO.

Sign Up

Maritime and offshore news trusted by our 105,933 members delivered daily straight to your inbox.

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up