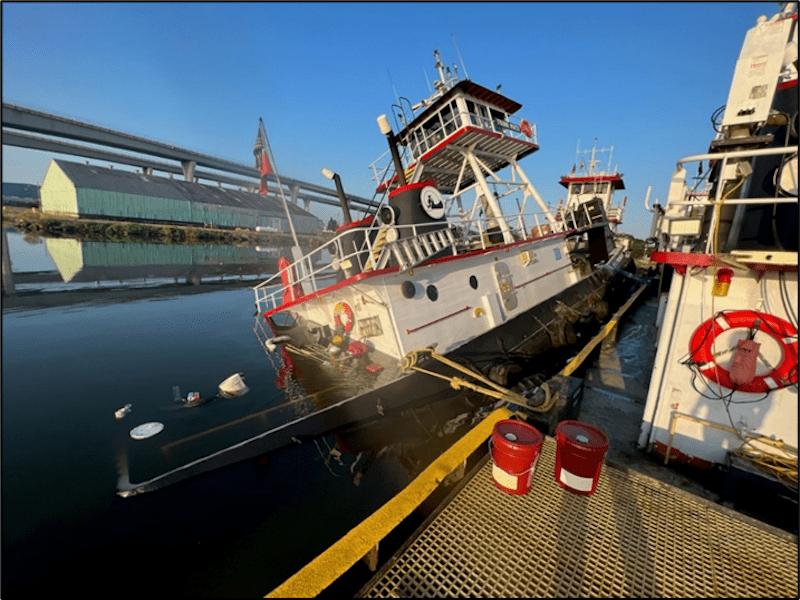

The National Transportation Safety Board (NTSB) says that an obstructed check valve on a bilge pump was the root cause behind the flooding and partial sinking of the towing vessel, Joanne Marie, last year. The vessel was moored and deactivated at a shipyard on the Harvey Canal near New Orleans when the incident occurred.

According to the NTSB, the Joanne Marie was found partially submerged one and a half days after being left unattended at the shipyard. Although no injuries were reported, the incident resulted in over $176,000 in damages.

Investigations revealed a wire nut lodged in a spring-loaded check valve on a bilge pump discharge line. This obstruction caused the valve to stick partially open. Additionally, the overboard shutoff valve before the through-hull pipe was found open. It was noted that the operating company’s procedures did not include instructions to close it upon deactivation.

The report also highlighted that the vessel’s cofferdam overboard discharge pipe was situated close to the water line. This allowed water to enter the discharge line. The combination of the stuck check valve and the open shutoff valve allowed water to overflow the cofferdam and flood the engine room.

The NTSB pointed out the operating company’s inadequate procedures for securing unattended vessels as a contributing factor to the incident. Since the sinking, the company has updated their deactivation checklist to include the closing of the overboard shutoff valve when a vessel is not connected to shore power.

The NTSB report stressed the importance of good marine practice, recommending that owners and operators develop comprehensive safety management systems for unattended or in layup vessels. Such systems should encompass closing through-hull fitting valves and tightening packing glands for propulsion shaft seals. Regular inspections of vessel spaces and installed high-water bilge alarms and fire detection systems can further ensure early detection and mitigation of potential safety risks.

Read the Report: Marine Investigation Report 24-07

Join The Club

Join The Club