Singapore has announced stringent new regulations for bunker fuel quality as it seeks to safeguard its reputation as a world-leading maritime hub. This move comes in response to a significant bunker fuel contamination incident that took place in 2022.

The Maritime and Port Authority of Singapore (MPA) has informed all licensed bunker suppliers about the implementation of enhanced testing parameters for marine fuel batches. These enhancements aim to increase efficiencies and cost-effectiveness by conducting the tests upstream in the supply chain, rather than for each individual delivery.

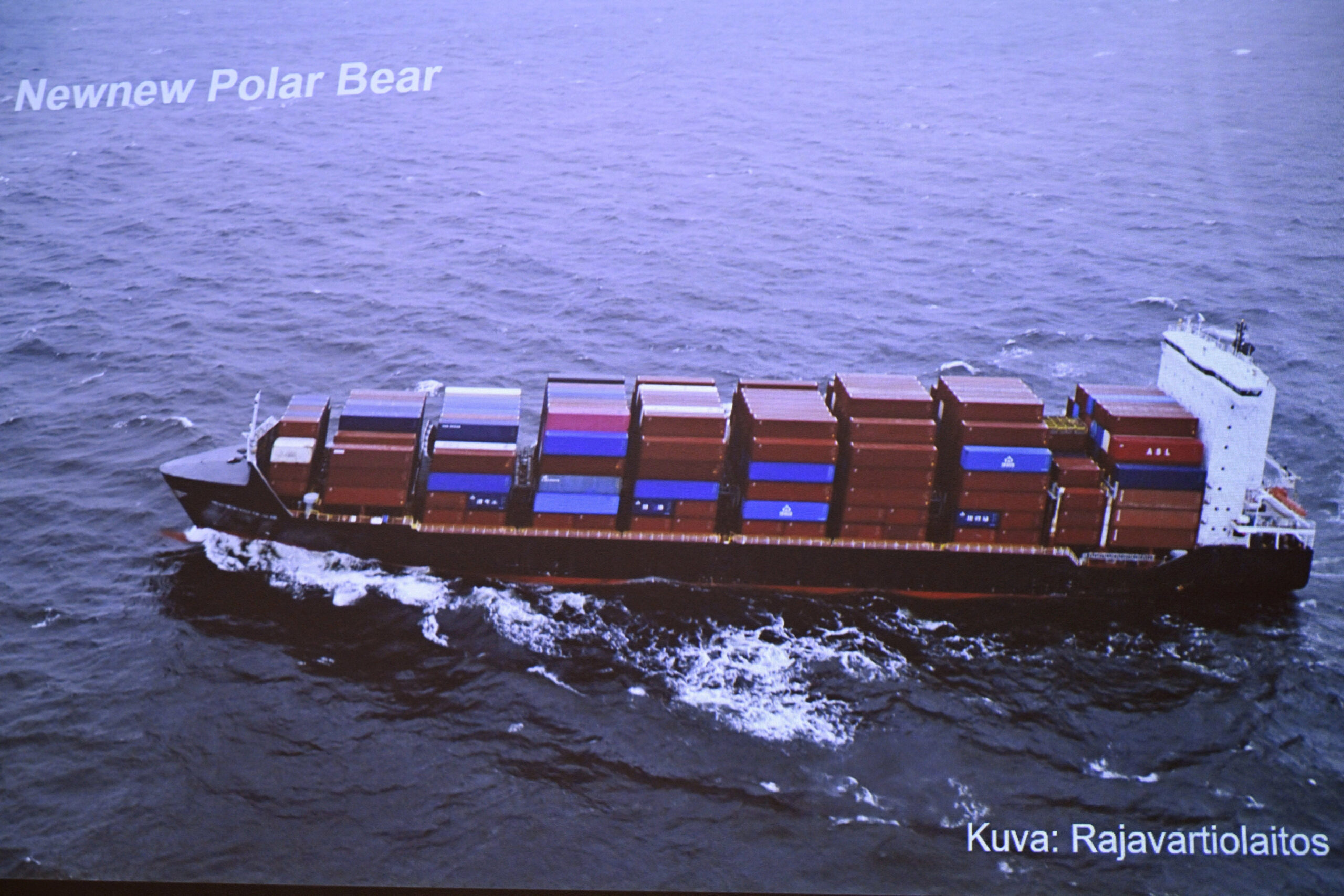

This new policy stems from a bunker contamination incident that occurred in Singapore in February 2022, where around 200 ships were supplied with High Sulfur Fuel Oil (HSFO) containing high levels of Chlorinated Organic Compounds (COC) in the Port of Singapore. An MPA investigation into the contamination revealed that the fuel in question was a blended product supplied by Glencore Singapore Pte Ltd, which was subsequently sold to PetroChina International (Singapore) Pte Ltd and then to about 200 ships in the Port of Singapore before the contamination was discovered. Approximately 80 of the ships reported issues with their fuel pumps and engines.

To address the issue, an Industry Expert Group (IEG), co-chaired by the MPA and Singapore Shipping Association (SSA), was established to boost the quality assurance of bunkers supplied in the Port of Singapore.

The IEG presented its recommendations to the MPA in mid-2023, which have been taken into account for these new regulations. Effective from June 1, 2024, all residual and bio-residual bunker marine fuel supplied in the Port of Singapore must not contain COC above 50mg/kg and must be free from inorganic acids.

For distillate and bio-distillate bunker marine fuel, bunker suppliers must also ensure they are free from inorganic acids. Additionally, residual marine fuels should be free from polystyrene, polyethylene, and polymethacrylate.

The MPA encourages all licensed bunker suppliers to maintain proper test records indicating that the current batch of bunker fuel supplied in the port of Singapore is free from these polymers.

For marine fuel that is blended using different fuel or feedstock batches, the tests must be performed after the blending and before delivery as bunkers in the Port of Singapore. The blending process is not permitted aboard the MPA licensed bunker crafts, and the Certificate of Quality (COQ) must be of the fuel prior loading to the bunker tanker before the product is delivered as bunkers in the port of Singapore.

Read the Maritime and Port Authority of Singapore Circular here.

Join The Club

Join The Club