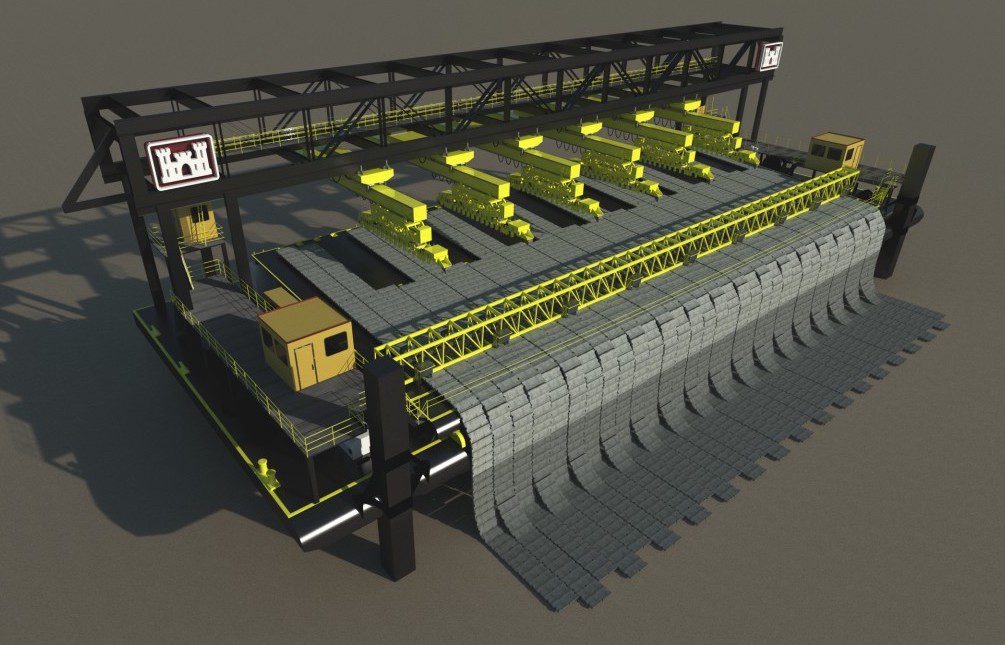

The 188’ x 74’ x 10’ Mat Boat designed by Bristol Harbor Group. Image courtesy BHGI

At the end of each summer, a specialized unit of the United States Army Corps of Engineers get to work on the Mississippi River laying thousands of slabs of concrete “mattress” to help prevent erosion and keep the critical waterway open to navigation.

The USACE Vicksburg District’s Mat Sinking Unit (MSU), which now encompasses around 50 full-time employees and 200 seasonal workers, first started in 1940 and covers a jurisdiction that includes Memphis, Vicksburg and New Orleans. The unit gets work during the months when when river stages are at their lowest, typically August to November, working long hours and living on quarter boats until the operation is complete.

During the 2018 season, the unit placed approximately 200,000 concrete squares along the Mississippi River, protecting against erosion and sloughing that threatens hundreds of billions of dollars worth of commerce that is required to flow freely up and down the Mississippi River System.

Now, nearly 75 years after the launch of the unit, a modernization project is underway that could help double the number of mat squares that can be placed in a season and improve safety for the crew.

The new Mat Boat, measuring 188m long by 74m wide, has been designed by Bristol Harbor Group in partnership with USACE Vicksburg District (MVK), USACE Marine Design Center (MDC), SIA Solutions LLC (SIA), and the National Robotics and Engineering Center (NREC).

NREC is designing the new robotic cranes and tying gantry, which will pick up concrete squares from the supply barge, place them on the Mat Boat’s launch deck, and tie the individual mat squares together to form one large mattress. As more squares are placed on the launch deck, winches payout cable, allowing the concrete fabric to slide down the launch deck. Once the appropriate number of squares have been connected, automatic clamping and tying units will cut the cables and let the mat slide off into the river.

On the current matboat system, crew members are responsible for the dangerous job of aligning, tying, clamping, and cutting the launch all while working on moving deck. But the new robotic systems will take over for much of this work, helping achieve a much faster production rate with greater safety of the crews.

“For 70 years, the Mat Sinking Unit has played a crucial role in protecting the banks of the Mississippi River from erosion, and the importance of that task cannot be overstated,” said Vicksburg District Commander Col. Michael C. Derosier upon closing of the 2018 season. “The Mississippi River serves as a vital commercial waterway and drains 41 percent of the nation’s water. It is the lifeblood of the U.S. economy.”

NREC is currently in the prototype phase of the project, with the first of the lifting arms and a segment of the tying gantry already built and under testing. And with the design now complete, it is now U.S. government to pick a shipyard begin construction of new vessel.

Here’s a video from 2013 explaining the operation:

Unlock Exclusive Insights Today!

Join the gCaptain Club for curated content, insider opinions, and vibrant community discussions.

Join The Club

Join The Club