China Hosts Foreign Naval Officials Amid South China Sea Tensions

By Laurie Chen QINGDAO, China, April 21 (Reuters) – The Chinese Navy on Sunday kicked off a biennial meeting of top foreign naval officials in the port city of Qingdao, in a...

Rolls-Royce provides equipment found on over 30,000 ships in 70 different navies around the world, including nearly every ship in the US Navy. I met up with Jay McFadyen, President – Rolls-Royce Naval Marine Inc at this year’s Sea Air Space Exposition in National Harbor, Maryland.

16 April 2012

RA: Jay, Rolls-Royce has a significant presence in a number of different sectors can you give us an overview of Rolls-Royce’s global business?

JM: We work across four segments, Civil Aero, Defense Aero, Energy and Marine. As part of that, the Marine Sector has been the fastest growing over the past decade. It’s roughly the second biggest piece of the company behind the civil aerospace sector.

Rolls-Royce has the biggest portfolio of marine equipment on board ships in the world, found on 30,000 vessels. We have 70 navies around the world that operate Rolls-Royce equipment, including most of the US Navy fleet operating at least some element of Rolls-Royce equipment on board, particularly controllable pitch propellers.

Within the marine business, which is headquartered in Singapore, we have over 7,000 employees around the world. Our three customer facing business units include Offshore, Merchant, and Naval. We also have a Services business supporting customers in all three.

Naval is the piece that I work in and I have the North American piece of Naval, but we operate globally. Within Naval we have around 800 people supporting our products and our customers around the world, predominantly based in the US and UK, although we have picked up some folks as part of our recent acquisition of ODIM and that’s given us two offices in Canada, one in Peterborough, Ontario, and one in Dartmouth, Nova Scotia.

RA: What is ODIM?

JM: ODIM is a subsea and seismic technology company. The part that falls into our Naval business is specialty handling equipment, such as winches, winch systems for sonar and launch and recovery frames.

RA: Why did Rolls-Royce pursue that?

JM: It was predominantly a strategic acquisition for seismic and subsea and they have some specialty equipment that extends into our offshore supply and support vessel business unit.

RA: I’ve noticed that a lot of the work that Rolls-Royce has been doing in that sector has been full scope. That is, the complete ship design, integrated bridge, as well as providing the engines as well.

JM: Exactly right. Around 60% of the value of the ship is found in the high value parts of the ship, such as the engines and propulsors. We design the ships and provide complete integrated power and propulsion systems, and equipment.

We’re looking at how do we mimic that sort of design and systems integration approach within naval, and we’re doing it with a tug and salvage vessel design which is in service with a number of navies, where we’re providing a vessel that is based on an offshore UT design as well as providing the handling and propulsion systems. The Rolls-Royce UT design is the benchmark for the offshore industry.

Going into the Naval side of the business, we have about 500 of the 800 people worldwide working with the US Navy. The way we like to differentiate ourselves is that we have 500 people that work in North America who wake up every day with their primary goal being to service the US Navy. We have a really dedicated team with a specific target customer and we’re working to solve problems for them.

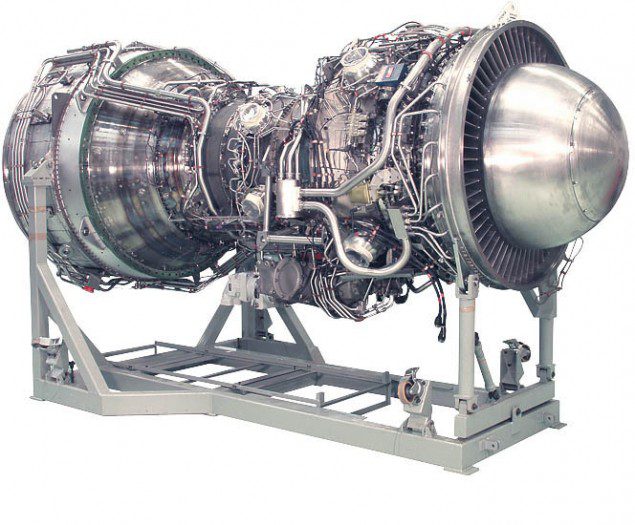

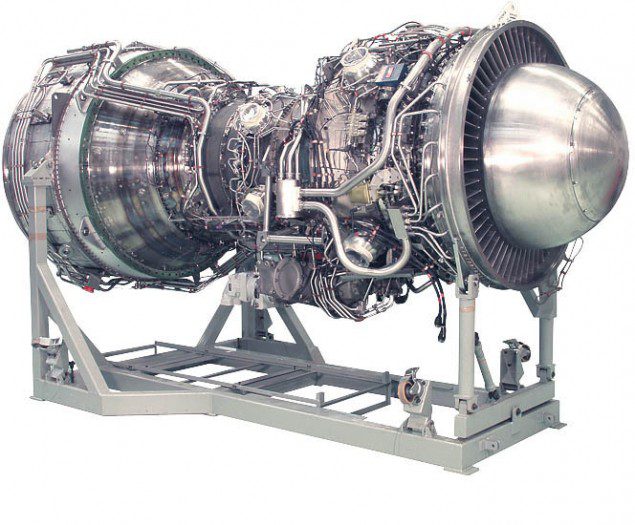

We have a number of different products, but one of the key ones within Naval is the gas turbine. These include the prime movers found on the Freedom-class Littoral Combat Ship and on the DDG 1000 class destroyers, as well as generator sets found on the DDG 51 class destroyer.

RA: Which gensets are on the DDG 51?

JM: The 501 gensets, AG 9140s.

RA: They used to be called something else in the past, weren’t they Allisons?

JM: They were. Rolls Royce purchased Allison back in 1995 and now it’s become a Rolls Royce-branded engine.

We have a gas turbine which we’ve offered as part of a proposal for the Ship-to-Shore Connector, which if successful, would be a new power size for the surface navy. What we’re doing though is taking the AE1107 engine, which powers the V-22 Osprey, and “marinizing” that for surface vessel use.

RA: What kind of changes are needed to “marinize” an engine?

JM: In this case, it’s truly a unique opportunity for us because in the application, it had to be designed to survive in the marine environment so basically from the inlet flange to the exhaust, there are really no changes. The changes are all external to the engine such as the power take-off shaft, the control system, the starter, and the interface to the fuel system. Other than that, it’s identical to the engine that’s on the V-22.

This is a terrific opportunity to the Navy because the Ship-to-Shore Connector and the V-22 would both be operating off the same platforms. So all the LPDs and LHAs, would all have V-22s on the deck, and Ship-to-Shore Connectors in the well deck. The Rolls-Royce engine is serviced through a thru-life support agreement where we have service reps that ride the ships, we have parts that are stocked in the Aviation area, and those assets can be deployed to the Ship-to-Shore Connector, so it makes a ton of sense from a logistics and maintenance perspective that those engines would work together on those platforms.

We’re very optimistic that the Navy will see the benefits there.

RA: Which kind of engines are found on the LPD 17-class ships?

JM: Those ships are diesel powered, but we will be able to take the aviation element of that and apply it to the Ship-to-Shore connector.

One of the other things that we see as part of a global company is that we have a service network that is distributed around the globe. As I mentioned, our Marine headquarters is located in Singapore, we have a Marine service shop in Singapore, and we also have relationships on the Air side with joint ventures around service that can be put to use with the Navy.

This comes into play with the potential forward basing of a handful of Littoral Combat Ships in Singapore, and we have the infrastructure in-country to provide repair and overhaul services there, so that you don’t have to take the MT30s and move them back and forth between there and the US if you need service. We also have trained service reps who can leave our service shop next to the Navy base and provide maintenance support. With the minimal manning structure of the LCS, there just aren’t the people or expertise on board to maintain the MT 30 engines, this work needs to be contracted out. Our assets in Singapore are ideally positioned to provide this service.

RA: So the Navy doesn’t do any sort of maintenance on these engines?

JM: They do MINIMAL work. It’s the day to day checking of filters, fluid levels, but once you get beyond that, they have to contract in a specialist. Considering it’s only 40 sailors on board, and the broad range of equipment found on the LCS, it’s really the only practical option.

RA: Historically, since the LCS program has been around, has the Rolls-Royce MT 30 engine worked out well?

JM: It’s really a relatively low maintenance engine, and very little intervention required to keep it up and running. You do have to perform the standard preventative maintenance activity though, and for that, you do need to bring on contract work to make that happen.

RA: And it hasn’t been a problem getting contract help in from Singapore to get this work done?

JM: Right now, the ship has moved from Milwaukee, to Norfolk, and now it’s home-based in San Diego.

RA: Ok, so it hasn’t deployed yet?

JM: It’s deployed, but it has deployed out of San Diego at this point. The plan is, next year, she’ll go over to Singapore for an eight-month deployment, and that’ll be the first test of whether the vessel can be supported abroad. We’re looking forward to doing what we can to make that successful.

RA: You touched on Rolls-Royce doing full scope work in the offshore community, how much work is being done by Rolls-Royce within the Naval community outside of engines?

JM: Quite a bit. Most US Navy ships have Rolls-Royce propulsion equipment, the old Bird-Johnson propellers, are part of Rolls-Royce, and with the LCS-5, we’ll be introducing a new axial-flow Rolls Royce water jet. So all the LPDs, LHAs, Cruisers, Frigates, DDGs, DDG 1000s, CVNs, they all have Rolls-Royce propellers. We’re doing the bulk of the service work for all the hub internals; the minor blade repair work is handled on-site by the Navy, and some of their contractors, but when it gets more complex, and they have to go into the internals of the propeller, all that work gets done at our factory in Walpole, Massachusetts.

RA: And these are Controllable Pitch Propellers (CPP)?

JM: For the most part. The DDG 1000 and the CVNs are fixed pitch.

RA: The DDG 1000s are fixed pitch?

JM: Because it’s electric-drive, you don’t need CPP. The same goes for the CVNs as they are reactor steam driven.

RA: And from what I hear, DDG 1000 will not have shrouded, nozzle-type propellers?

JM: Right, exactly. Although useful at slower speeds, the shroud increases the vessel drag at high speed.

RA: It’s a quite a different mindset than the commercial industry. It’s all about speed in the Navy, full go all the time.

JM: There’s a growing concern in the Navy about not operating at full speed all the time and trying to conserve energy. More and more, we’re trying to offer energy efficient solutions. The DDG 1000 is a great example of an integrated electric power system because we have two large, 36 megawatt MT 30 engines, and two smaller, MT 5s that are 4 megawatts each, and so all of that actually goes into a single power island. So you run the engines based on the most efficient way to provide the required power. Gas turbines are most efficiently operated at full power, so you basically turn the engines on sequentially so that you’re able to operate most efficiently based on your operational profile. Within that electrical power grid, you’ll pull off what you need for hotel load, combat systems, auxiliary, propulsion etc.

RA: How fast can the ship go with both main engines down and using only the 4 MW auxiliary engines?

JM: To be honest, that’s classified by the Navy but yes, the idea is that you can propel the ship using the smaller engines in a loiter-type scenario.

RA: The cruise industry, and a number of other industries are looking at using DC power as a major onboard system. I know that ABB has been pushing this idea fairly aggressively lately making points on how it would increase power efficiency and reduce the cabling which would both reduce weight and cost. I was wondering if the Naval industry was looking at this?

JM: Let me turn that over to my electrical expert here, Ryan Frommelt

RF: So the Navy has what they call, the next generation, integrated propulsion system road map, and on that road map, DC is on there. DC power is used on the Virginia-class submarine, and they have a very smart system with how they used their steam-turbine derived power.

The surface navy is trying to integrate some of that, and progress along the path to get there, and I think DC is on the path, high frequency AC is on the path, and it’s just a matter of how much they are willing to invest to get there, and what they will be able to do with it.

From a Navy perspective, I think a lot of the things they are faced with is that there are no new ships coming on line. They have to work within DDG 51 and since DDG 51 uses a 450V 60Hz AC system, in order for a big step change into DC, you’re really looking at a new ship.

Since there are no new ships on the books, it’s kind of tough to push through those leapfrog technologies when you’re using that same platform. There’s the Flight III platform, but it’s still a DDG 51-based design.

DC is on roadmap, and how quickly you can get to that checkpoint is a function of how much the Navy is willing to put forth, as well as the new platforms that may or may not be moved forward.

JM: The last thing I really wanted to highlight was our recent joint venture with Daimler, where we’ve joined together to purchase Tognum, which is the parent company of MTU. One of things that was missing from Rolls-Royce’s marine portfolio was a high speed diesel, and this will now give us access to the high speed diesel marketplace. MTU also has a tremendous system integration capability that we think we can leverage to pull together the rest of the Rolls-Royce suite of products that can be put to effective use in naval applications.

RA: Very nice meeting you today Jay, thanks for the opportunity to chat.

Join the gCaptain Club for curated content, insider opinions, and vibrant community discussions.

Join the 105,917 members that receive our newsletter.

Have a news tip? Let us know.

Access exclusive insights, engage in vibrant discussions, and gain perspectives from our CEO.

Sign Up

Maritime and offshore news trusted by our 105,917 members delivered daily straight to your inbox.

Essential news coupled with the finest maritime content sourced from across the globe.

Sign Up